Sheet Metal Fabrication

Services at Prototek

Prototek’s sheet metal fabrication services offer:

- Variety of Production-Grade Materials

- Price Breaks on Large-Volume Orders

- Precision and Repeatabilities

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- 100+ Materials

- 40+ Surface Finishes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

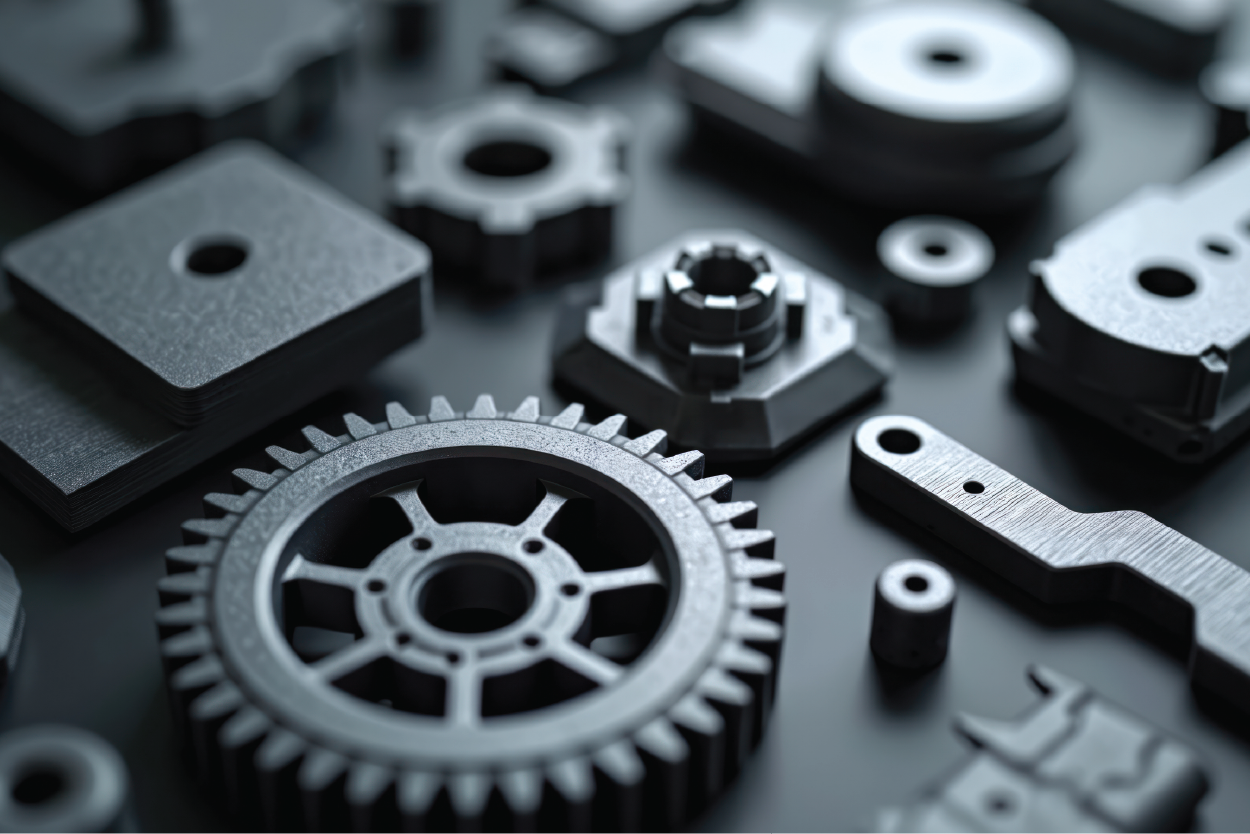

Our Custom Sheet Metal Fabrication Services

Our precision sheet metal services offer custom-made metal parts and components for various industries and applications. Prototek’s skilled engineers and technicians use advanced equipment and techniques to create precise, high-quality products from stainless steel, aluminum, copper, and titanium materials. Additionally, we can manufacture anything from simple brackets and enclosures to complex assemblies and structures. Furthermore, our services include design and engineering support, metal cutting, bending, punching, welding, painting, and finishing. Moreover, we provide rapid prototyping and low-volume production options to meet specific project needs. Most importantly, we deliver cost-effective, reliable solutions that meet our clients’ quality, performance, and turnaround time requirements. Whether it’s a one-off project or a production run, our team is ready to provide exceptional sheet metal fabrication work that exceed expectations.

Bending & Forming

OEM:

Amada

Lead Time:

1 -15 Days

Max Dimensions:

Press Brake Tonnage: 90 tons

Maximum Sheet Metal Bend Length: 10 ft

Sheet Thickness: 0.003 in – 0.375 in

Laser Cutting

OEM:

Amada, Beam Dynamics, Epilog, IPG

Lead Time:

1 -15 Days

Max Dimensions:

120 in X 60 in

Thickness: 0.875 in

Waterjet Cutting

OEM:

Flow

Lead Time:

1 -15 Days

Max Dimensions:

Linear Straightness: ± 0.0021 in

Repeatability: 0.0014 in

Custom Sheet Metal Materials

Prototek Digital Manufacturing offers a wide selection of sheet metal and fabrication materials to meet various manufacturing needs. Our team of skilled professionals is proficient in working with materials such as stainless steel, aluminum, and carbon steel. With our dedication to excellence and innovation, you can depend on our extensive expertise to bring your concepts and visions to life.

Metals

- Aluminum

- Brass

- Bronze

- Copper

- Nickel Based High Temperature Alloys:

- Inconel

- Invar

- Kovar

- Nitronic 60

- Stainless Steel

- Steel

- Titanium

- Tool Steel

Does your project require a material not on our list?

Let us know if your project requires materials that are not on the list! We can accommodate other material requests, but quotes may need more time while we source the material.

Sheet Metal Finishes

After cutting, bending, and forming sheet metal– finishing is the step in precision sheet metal fabrication because it determines the appearance and durability of the final product. Sheet metal fabricators may use various finishing techniques such as painting, powder coating, polishing, anodizing, or plating to provide additional protection against corrosion and wear. The chosen finishing technique depends on the metal product’s intended use and the designer’s aesthetic preferences. For example, a high-quality finish can enhance the product’s visual appeal and increase its value. Overall, finishing is crucial in creating a successful sheet metal fabrication project. Choosing a qualified and experienced sheet metal fabricator like Prototek can ensure the desired result is essential.

High Quality Rapid Prototyping and Production Parts with Sheet Metal Fabrication

Prototek Digital Manufacturing provides high-quality rapid prototyping and production parts using advanced sheet metal fabrication capabilities. Our team of skilled engineers and technicians utilizes the latest technologies to ensure precision, efficiency, and cost-effectiveness for all your manufacturing needs. Additionally, we offer services such as laser cutting, waterjet cutting, and press brake operations to accommodate projects of varying scales. Whether you need small batches or high-volume production, you can rely on Prototek to bring your ideas to life with exceptional quality and quick turnaround times.

Learn More About Prototek's Sheet Metal Fabrication Services

Through our resources, you can discover the complexities of Sheet Metal Fabrication and gain insights into creating top-notch designs specifically tailored for this cutting-edge technology.

Rapid Prototyping: Bridging Ideas and Reality

In today's fast-paced world, rapid prototyping makes turning innovative ideas into products easier than ever. By utilizing advanced technologies like 3D printing and machining, designers...

What Is Kovar and Why Is It Important?

Kovar is a significant nickel-iron alloy widely used in electronics, aerospace, and medical devices. Developed in the 1920s, Kovar possesses unique properties, such as expanding...

Composite Materials: Innovations Shaping the Future

Composite materials are transforming industries with strength, lightweight nature, and design flexibility, particularly in aerospace and renewable energy. Advancements like nanocomposites and 3D printing enhance...

Precision Sheet Metal Fabrication FAQs

Sheet metal fabrication is the process of creating metal parts and products by cutting, bending, and forming thin sheets of metal. This versatile manufacturing technique allows for the production of a wide range of components, from simple brackets to complex enclosures. Prototek’s skilled team leverages advanced equipment and techniques to deliver high-quality sheet metal parts tailored to your specific requirements.

At Prototek, we offer a wide range of sheet metal finishing options to meet your specific requirements. Our capabilities include powder coating, plating, anodizing, and painting, ensuring a durable and visually appealing final product. Our team of experts will work closely with you to determine the optimal finish for your project, delivering high-quality results that exceed your expectations.

Sheet metal fabrication is precise, cost-effective, and versatile solutions for your manufacturing needs.

Sheet metal fabrication can be labor-intensive and limited design flexibility compared to other manufacturing methods.

Absolutely! Prototek Digital Manufacturing offers state-of-the-art capabilities such as waterjet and laser for cutting sheet metal.

Why choose Prototek's sheet metal fabrication to manufacture your project?

Prototek’s sheet metal fabrication services offer unparalleled quality and precision to bring your project to life. With state-of-the-art equipment and a team of skilled technicians, we deliver exceptional results tailored to your specifications. Our commitment to innovation and attention to detail ensures your project is manufactured to the highest standards, meeting your timeline and budget requirements. Choose Prototek for your sheet metal fabrication needs and experience the difference our expertise can make.