Innovation to Scale with Prototek

Elevate your projects with Prototek’s digital manufacturing solutions. We support your vision whether you need quality rapid prototyping or production runs.

- Instant and Engineer-Assisted Quotes

- 100+ Materials

- 40+ Surface Finishes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- 100+ Materials

- 40+ Surface Finishes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

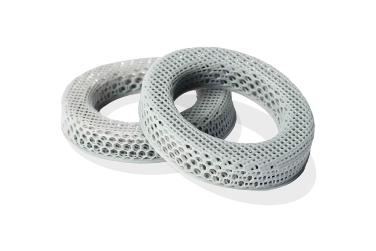

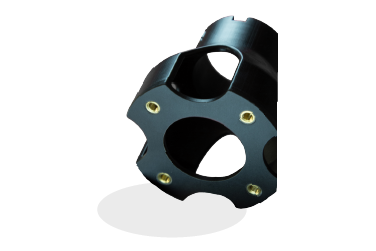

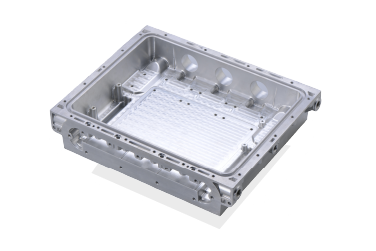

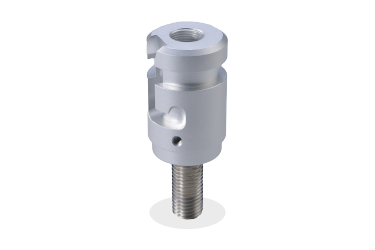

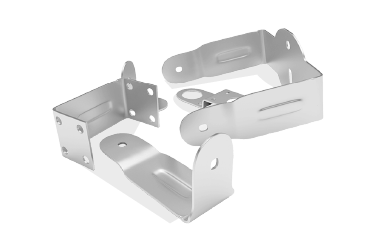

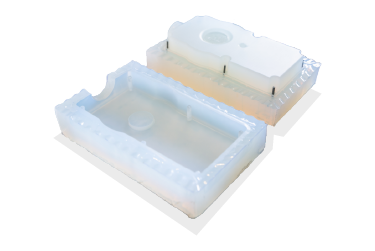

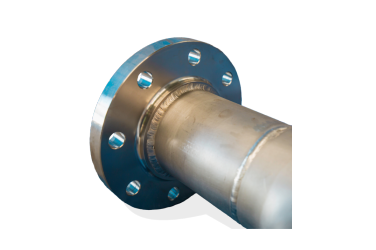

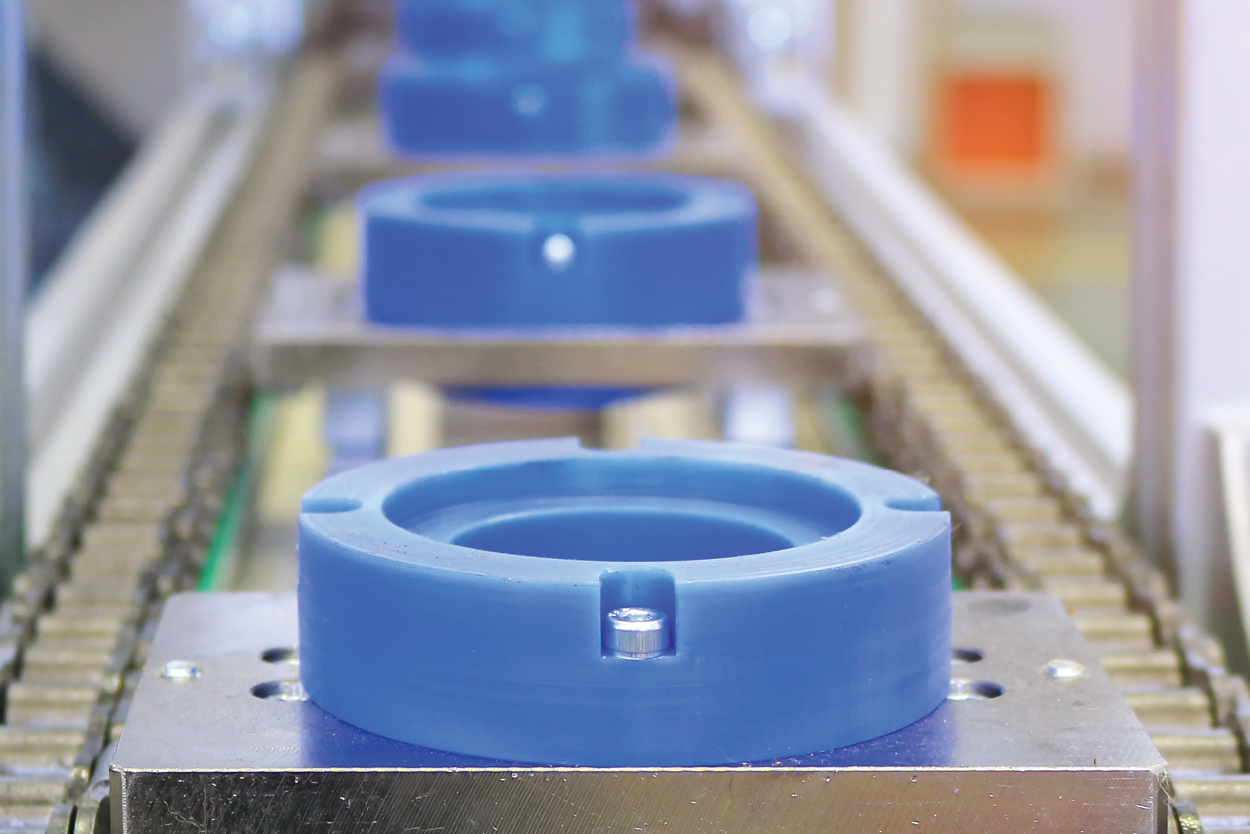

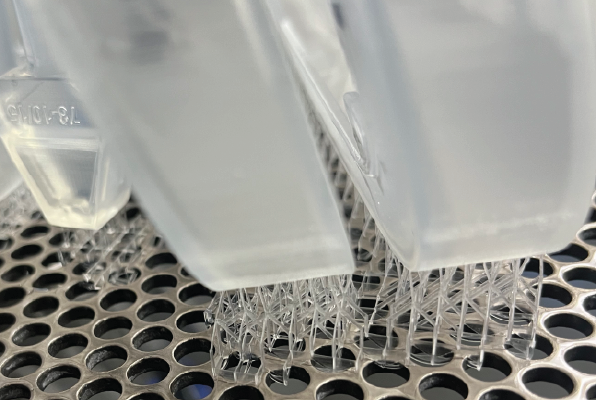

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

Manufacturing Services

Transforming Ideas into Reality: From Prototyping to Production

At Prototek, we offer a comprehensive solution for your needs, from prototyping to production. Our primary objective is accelerating your product development while maintaining high quality through our advanced manufacturing methods. With our extensive experience, we develop tailored solutions for your project’s unique challenges, ensuring a swift and efficient process.

When you’re ready to start, our manufacturing experts will work closely with you in a collaborative process. We work together to improve efficiency, lower costs, and enhance the quality of your product. We aim to help you get to market quickly and successfully. Let us help you turn your ideas into reality with the precision and speed you deserve.

Prototek's Services

What does innovation to scale mean?

Innovation to scale means we support you at every stage of your product’s life cycle. We have developed a comprehensive suite of services that includes technologies, materials, and a solutions-driven team to guide you from ideation and concept development to on-demand production. Whether you’re facing challenges or celebrating successes, we’re here to help.

Rapid Prototyping

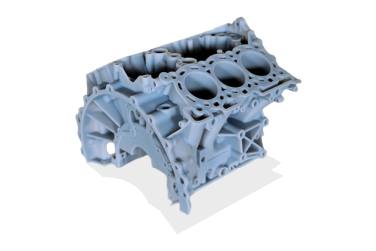

Rapid prototyping is the quick creation of physical parts, assemblies, or complete products using 3D printing and CNC machining methods. This approach helps companies test and improve product designs quickly and affordably before starting large-scale production.

Benefits of Rapid Prototyping

- Accelerated Product Development

- Reduced Time to Market

- Quick Design Iterations for Validation

- Cost-Effective

- Excellent Product Quality

- Stunning Visual and Concept Models

- Form, Fit, and Function Prototypes

On-Demand Production

On-demand production means making products or parts only when customers request them. This method helps businesses be more flexible, lowers inventory needs, and speeds up delivery times to meet each customer’s unique needs.

Benefits of On-Demand Production

- Reduced Inventory and Storage Costs

- Quick Response to Design Changes and Customization

- Minimized Waste and Overproduction

- Increased Supply Chain Flexibility and Agility

- Faster Time to Market for Customized Designs

- Precision and Repeatability

- More Effortless Responsiveness to Market Trends and Demands

Industries Prototek Serves

Join a community of thousands of industry leaders who are driving innovation. We focus on progressing and achieving outstanding customer results using our technologies, materials, and expertise.

Prototek IQ

Intelligent Instant Quoting

Prototek transforms custom manufacturing with its 3D printing and CNC instant quoting platform. This platform is a one-stop shop for on-demand additive manufacturing, CNC machining, and sheet metal fabrication. It serves various industries, including aerospace, defense, medical, and robotics.

- Get instant pricing.

- Lead times.

- DFM feedback for your 3D model.

Customer Spotlight:

Pratt Miller

We are excited to share a testimonial from Pratt Miller regarding our 3D printing services at Prototek! Their commitment to innovation aligns perfectly with our mission, and we are proud to support them.

Pratt Miller recently used our fast and precise 3D printing for their wind tunnel testing project.

- Faster Prototyping

- High-Quality Wind Tunnel Test Parts

- A Partnership Dedicated to Innovation

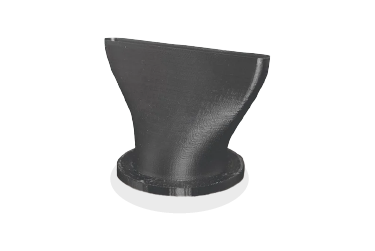

Take your prototype to the next level with a Visual Model from Prototek!

At Prototek, we know that showcasing your work is crucial. We offer various in-house services to create high-quality appearance models of your final design. Our team will help you balance technology, aesthetics, function, and budget to bring your idea to life.

- Showcase the actual colors, materials, and finishes that you hope to achieve in the final product.

- Show product viability prior to manufacturing with human interaction.

- Begin marketing with your photo ready model such as promotional graphics and packaging.

What sets Prototek Apart from our Competitors?

Prototek Digital Manufacturing distinguishes itself from competitors by providing advanced manufacturing services. We prioritize quality and innovation while delivering exceptional customer service.

Our focus on new opportunities in digital manufacturing, through innovative technologies and materials, enhances the customer experience and enables customizable solutions.

Prototek Digital Manufacturing Locations

We have facilities throughout the United States, which helps us serve our customers effectively. Furthermore, our strong logistics network enables us to process and ship orders quickly. As a result, we deliver fast, no matter our customers location. Our clients can rely on us to provide the products they need on time, helping them stay competitive in their markets. In addition, this efficiency reinforces our commitment to customer satisfaction and strengthens our partnerships. Ultimately, our goal is to ensure that we meet and exceed the expectations of all our clients.

Our Locations

Prototek's Featured Case Studies

Functional Prototyping with NICE Recovery

Medical Industry

NICE Recovery is a medical device company that focuses on personalized therapy. It partnered with Prototek to create working prototypes. Its new product, the NICE ROCC, cools palms without ice or water, providing precise heat removal and comfort. Using 3D printing, it was able to develop this device quickly in time for the Strongest Man on Earth competition.

Switchgear Drives Performance with Form, Fit, & Function Prototypes

Automotive Industry

The F-150 Switchgear is a powerful electric truck designed for driving on roads and off-road paths. Ford Performance and RTR Vehicles developed it with advanced suspension systems, high ground clearance, and substantial parts for rugged terrains. We will examine how we prototyped the truck’s body, focusing on its design and fit. We’ll also explore the 3D printing technologies and materials used in its creation.

Prototek's Latest Articles

What Is Kovar and Why Is It Important?

Learn about Kovar, an important nickel-iron alloy used in electronics, aerospace, and medical devices. Since its development in the 1920s, Kovar has unique features like expanding like glass and resisting corrosion. These properties make it essential to create strong seals in complex systems. Understanding Kovar can improve your projects and...

Designing Custom Jigs and Fixtures for Manufacturing.

These essential tools enhance precision and consistency and boost productivity on the shop floor. Discover how well-designed jigs and fixtures can streamline operations, reduce errors, and improve product quality. From material selection to innovative manufacturing methods like CNC machining and 3D printing, learn how to create tailored solutions that meet...

Composite Materials: Innovations Shaping the Future

Composite materials are transforming industries with strength, lightweight nature, and design flexibility, particularly in aerospace and renewable energy. Advancements like nanocomposites and 3D printing enhance performance and create new opportunities. With a history of thousands of years, composites continue to evolve, offering sustainable solutions for modern needs.

Prototek's Latest News

Prototek Expands Instant Quoting Platform with Sheet Metal

Prototek is revolutionizing the way engineers and buyers access manufacturing services with the expansion of its AI-powered instant quoting platform, Prototek IQ. Now featuring instant quotes for both 2D laser-cut and complex 3D formed sheet metal parts, customers can effortlessly upload CAD files and configure their needs.

Prototek Promotes Jason Kopras to VP of Digital Commerce & Marketing

Prototek is excited to announce the promotion of Jason Kopras to Vice President of Digital Commerce & Marketing. In this crucial role, he will drive a strategy that aligns sales, marketing, and digital commerce, focusing on enhancing online growth and customer engagement. Jason’s vision will elevate Prototek's digital presence and...

Prototek Names Ed Graham as VP & GM of Additive

Prototek is excited to share that Ed Graham has been promoted to Vice President & General Manager of its Additive Business. With 25 years in the additive industry, Graham's leadership will drive Prototek into a new phase of growth and innovation. Taking full responsibility for profits and losses, Graham plans...

What are our customers saying about us?