Blog

Take a look at our collection of case studies and articles to help you stay informed and explore digital manufacturing options further.

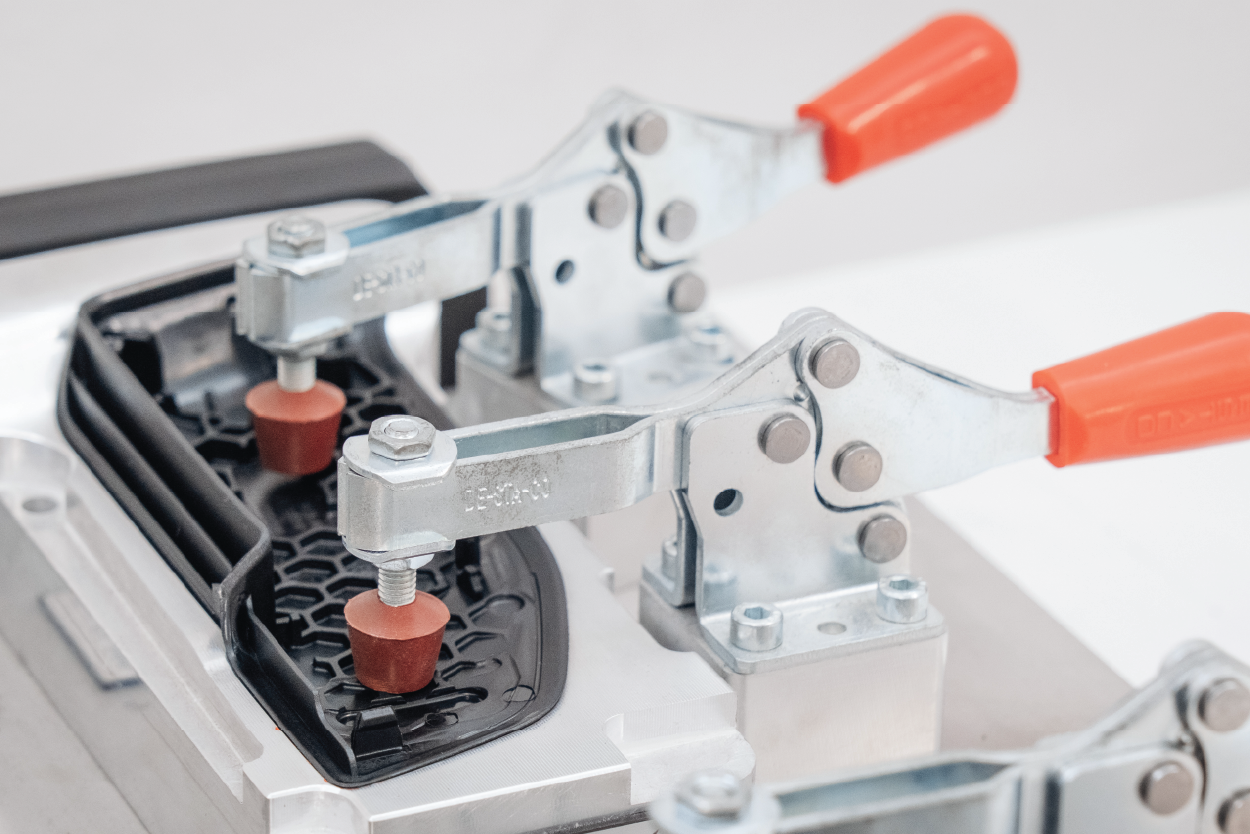

Case Study Spotlight: Switchgear Drives Performance

Ford and RTR Vehicles drive performance with functional testing for their collaborative project, the electric Switchgear, with Prototek’s SLA.

- All

- Article

- Design

- Case Study

What Is Garolite and Why Is It Important?

Garolite is a versatile composite material that has transformed the aerospace and electronics industries with its exceptional strength, lightweight nature, and resistance to heat and chemicals. Understanding its unique properties can significantly enhance your projects, whether you're designing circuit boards or creating durable tools.

Rapid Prototyping: Bridging Ideas and Reality

In today's fast-paced world, rapid prototyping makes turning innovative ideas into products easier than ever. By utilizing advanced technologies like 3D printing and machining, designers can quickly create, test, and refine concepts. Rapid prototyping can significantly boost your product development in automotive, medical, and consumer electronics.

3D-Printed Carbon Fiber Applications

Explore 3D-printed carbon fiber is changing industries like aerospace and automotive by creating substantial, lightweight parts. You can find it in high-performance car parts and custom prosthetics, making it a key development in manufacturing.

What Is Kovar and Why Is It Important?

Kovar is a significant nickel-iron alloy widely used in electronics, aerospace, and medical devices. Developed in the 1920s, Kovar possesses unique properties, such as expanding similarly to glass and resisting corrosion. These characteristics are crucial for creating strong seals in complex systems. By understanding Kovar, you can enhance your projects

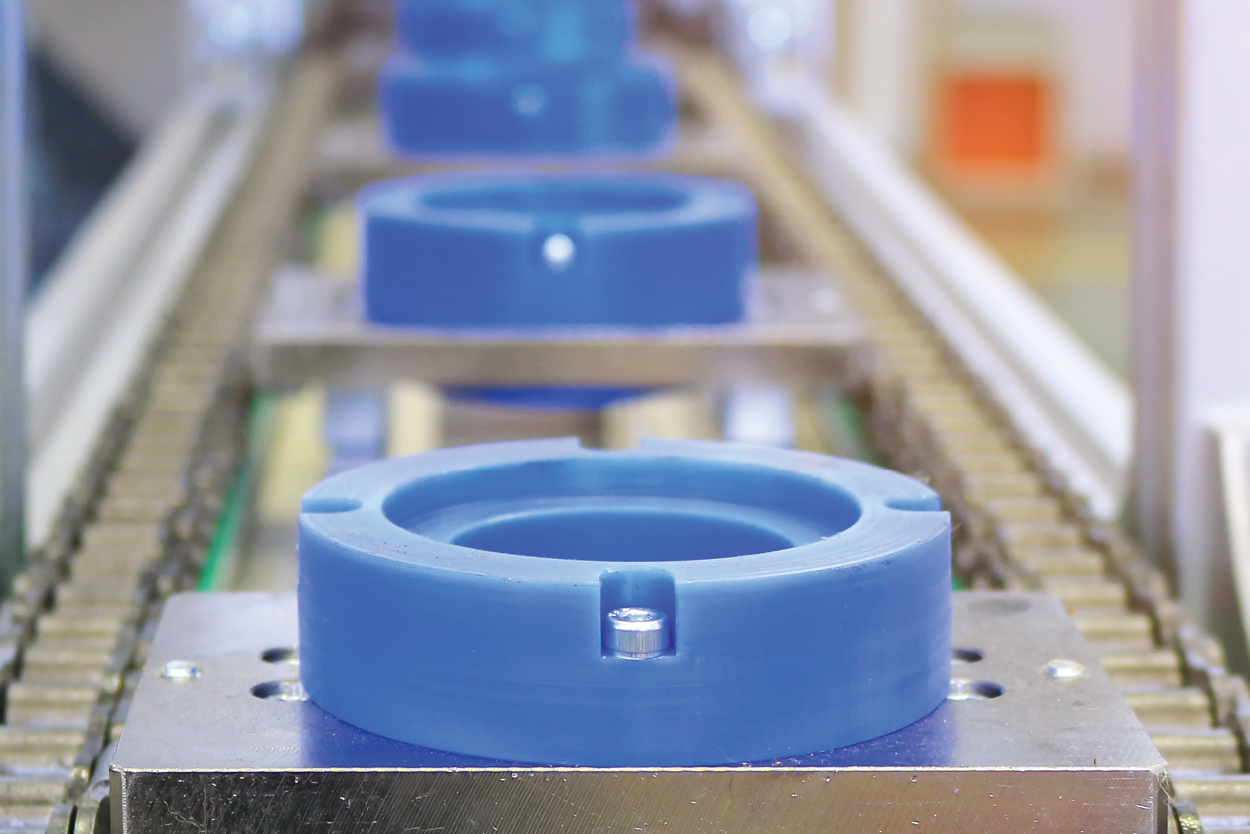

8 Compelling Benefits of Cast Urethane Manufacturing

This production method provides excellent cost-effectiveness, remarkable material versatility, and superior durability, making it an ideal choice for prototypes, small batches, and custom projects. With rapid prototyping capabilities and a low tool investment, you can quickly and affordably bring your ideas to life.

Clear and Translucent 3D Printing Materials

Explore clear and translucent 3D printing materials such as Accura® 60 and Somos® BioClear, along with their applications, benefits, and post-processing techniques to elevate your 3D printing projects. Unlock your creativity and turn your ideas into reality with our insights!

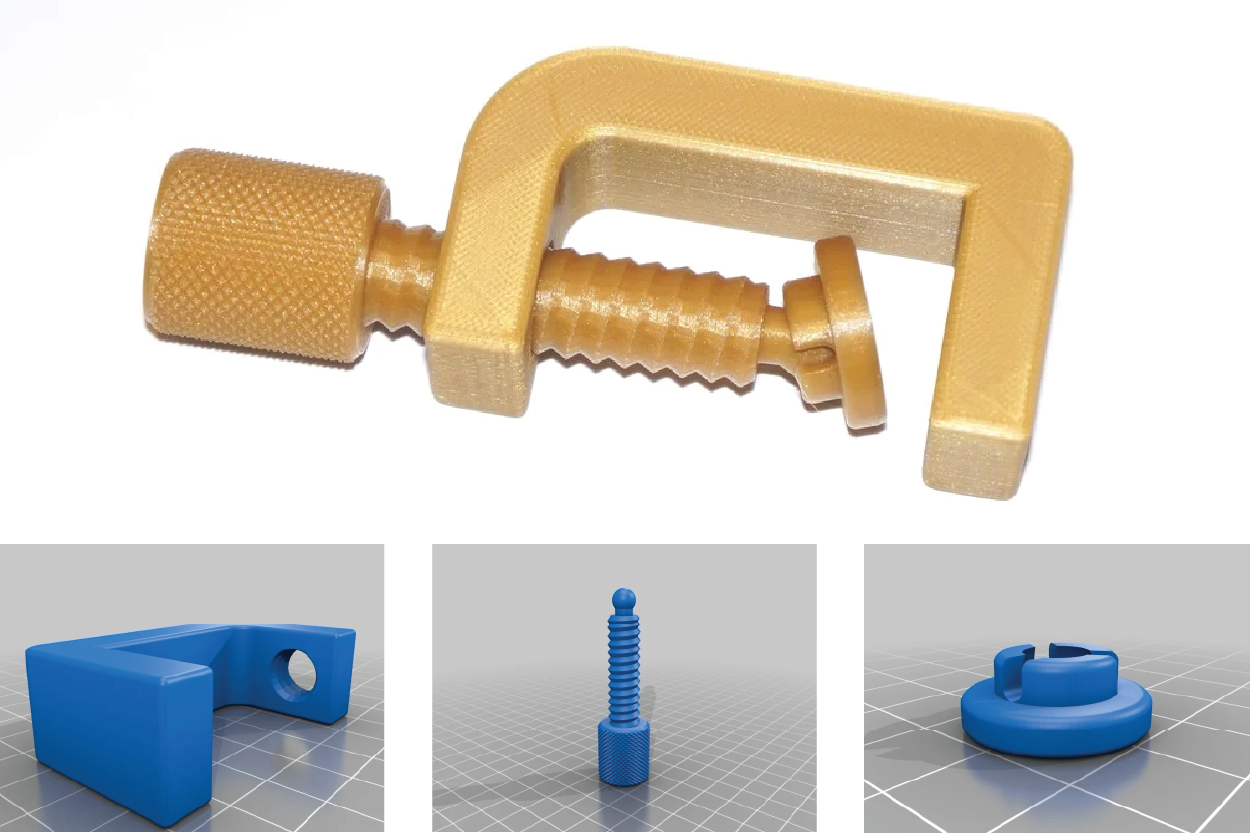

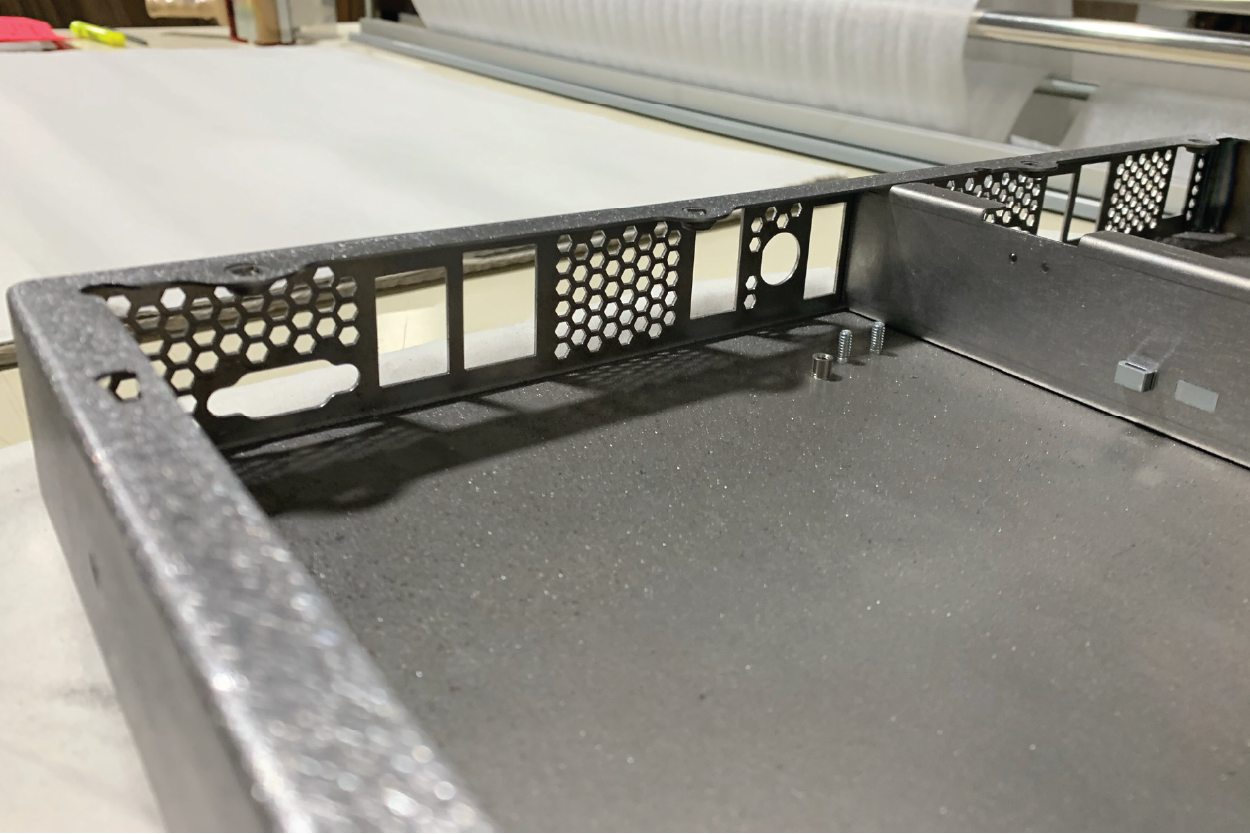

Custom Jigs and Fixtures: Intro to Designing for Manufacturing.

These essential tools enhance precision and consistency and boost productivity on the shop floor. Discover how well-designed jigs and fixtures can streamline operations, reduce errors, and improve product quality. From material selection to innovative manufacturing methods like CNC machining and 3D printing, learn how to create tailored solutions that meet

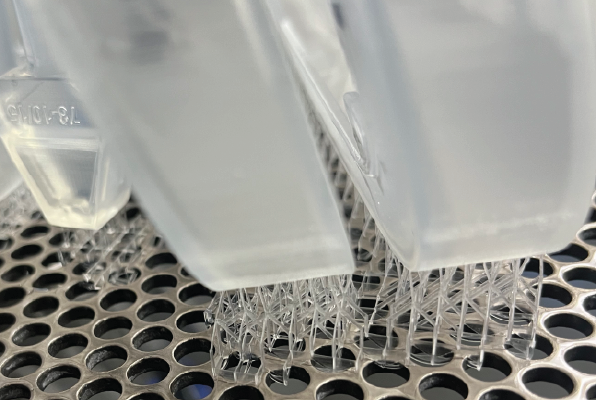

What Are 3D Printed Supports and Why Are They Important?

Understanding the crucial role of support structures in 3D printing. They stabilize designs, prevent failures, and improve quality across techniques like stereolithography and fused filament fabrication. To enhance your prints, minimize overhangs, and choose the proper support.

Composite Materials: Innovations Shaping the Future

Composite materials are transforming industries with strength, lightweight nature, and design flexibility, particularly in aerospace and renewable energy. Advancements like nanocomposites and 3D printing enhance performance and create new opportunities. With a history of thousands of years, composites continue to evolve, offering sustainable solutions for modern needs.

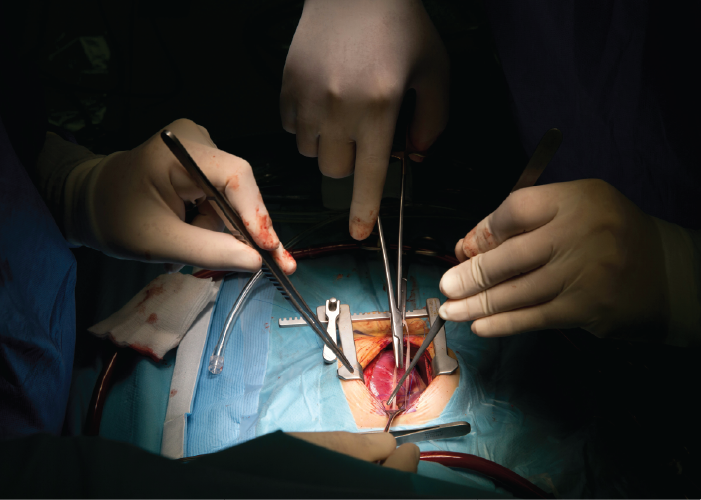

Sheet Metal Fabrication in the Medical Industry

Choosing the right materials is essential for patient safety and effective care in medical settings. This blog post examines what makes sheet metal suitable for medical use. Key factors include biocompatibility, corrosion resistance, and hygiene. Learn how materials like stainless steel, aluminum, and titanium provide reliability in medical applications.

Advancements in Manufacturing Technologies for Shipbuilding

The manufacturing of parts for ships is a crucial aspect of the maritime industry. This process involves various methods, materials, and technologies to ensure that vessels can withstand the harsh conditions of the sea. In this blog post, we will explore the key components of ship parts manufacturing.

Why Are STL Files Important in 3D Printing?

STL files are crucial for 3D printing, as they convert 3D models into physical objects. If you're involved in additive manufacturing, understanding STL files is essential. This post will highlight their importance and how they enable the creation of custom parts and products.

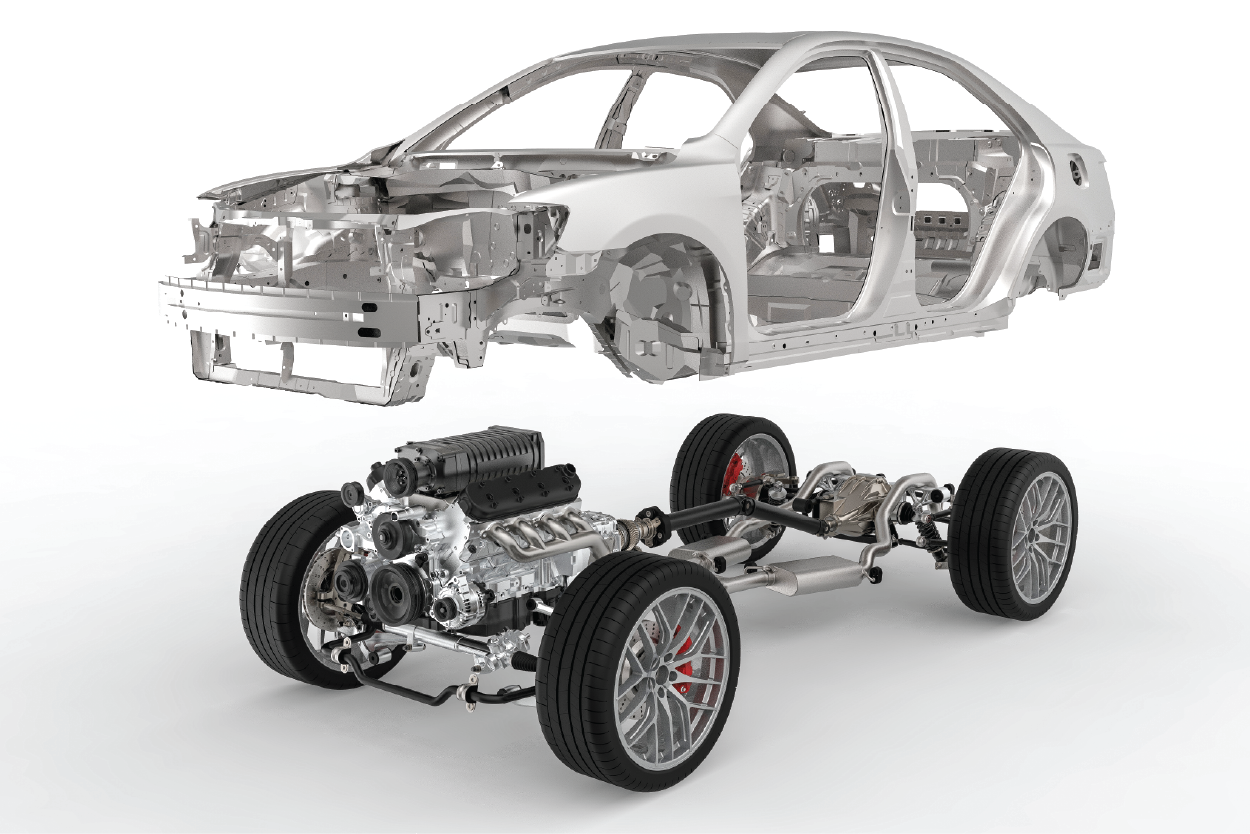

Sheet Metal Fabrication in Automotive Design

Sheet metal fabrication creates strong, lightweight, and attractive parts for the automotive industry. This manufacturing process improves the safety, performance, and fuel efficiency of body panels and engine components. Learn about the new techniques and advancements shaping modern car design significantly as the industry shifts toward electric vehicles and sustainable

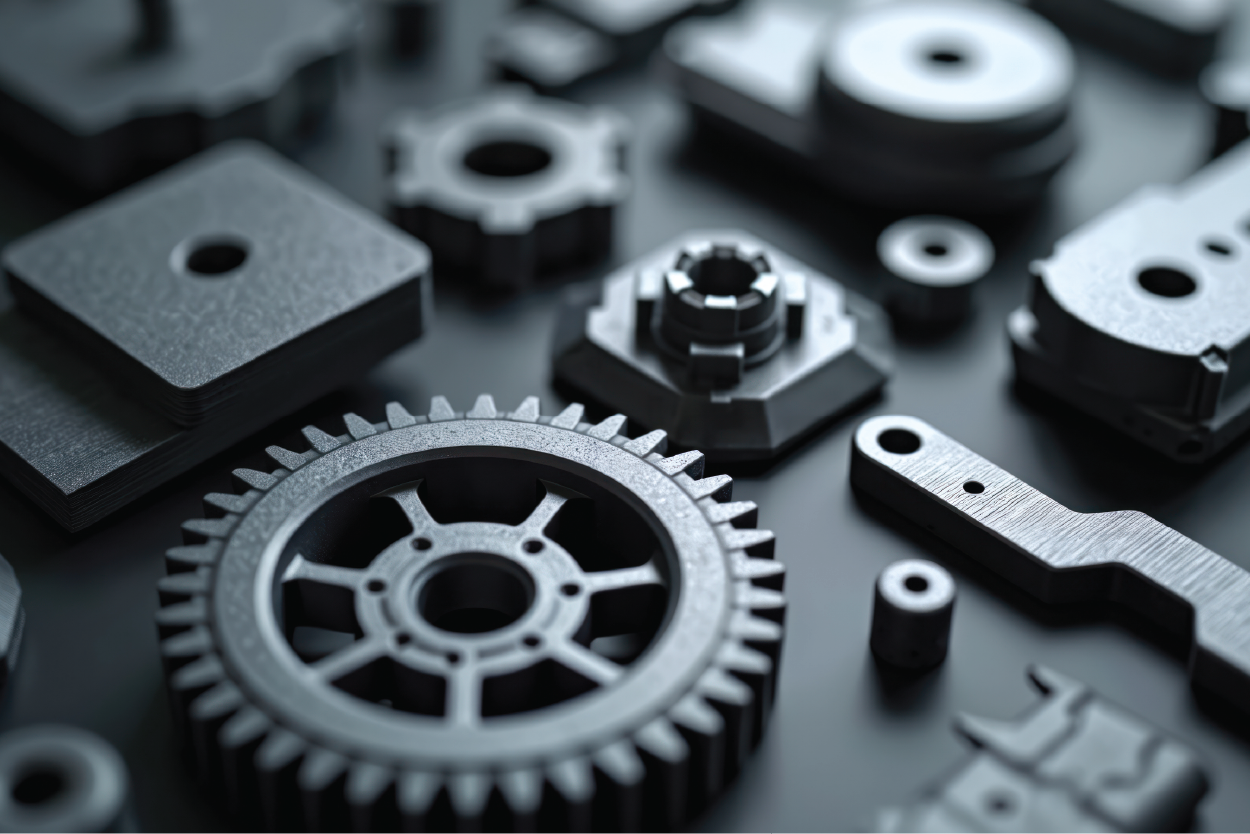

CNC Machining: Plastic Materials

As industries increasingly demand precision and versatility, our advanced capabilities can turn your ideas into reality. From lightweight and corrosion-resistant acrylic to durable polycarbonate and flexible nylon, each plastic type offers unique benefits for your projects. Whether you're in automotive, aerospace, medical, or consumer goods, machined plastic components are revolutionizing

The Importance of Sheet Metal Fabrication In Aerospace

Precision sheet metal fabrication is vital in aerospace, where safety and innovation are critical. Every detail is essential, from structural strength to weight reduction and aerodynamic performance. Techniques like laser cutting and welding create reliable parts that withstand extreme conditions.

Vapor Smoothing: The Secret to Professional-Looking 3D Prints

Enhance your 3D prints with vapor smoothing! This technique eliminates layer lines for a glossy finish, improving aesthetics and durability. Perfect for industries like aerospace, automotive, consumer products, and medical, Prototek's vapor smoothing service can elevate your projects.

Jigs and Fixtures What are the Differences?

Understand the differences between jigs and fixtures to enhance your manufacturing process. These tools improve accuracy and efficiency, resulting in high-quality outcomes. Effective use of jigs and fixtures can boost productivity in industries like aerospace and automotive. Check out our guide for insights on using these tools in your next

Can Tariffs Revitalize Manufacturing in the USA?

Can tariffs help US manufacturing? Many think tariffs are necessary to protect domestic industries from offshoring and unfair trade practices. Tariffs can create jobs, encourage local investment, and improve national security. This article looks at how smart tariffs can help American manufacturers and impact the future of the US economy.