Sheet Metal Fabrication

Services at Prototek

Parts in days anywhere in the USA.

Our custom Sheet Metal Fabrication offers:

- Variety of Production-Grade Materials

- Price Breaks on Large-Volume Orders

- Precision and Repeatabilities

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team begins production once the project specifications are finalized and the quote is accepted.

When the part has been completed and finished, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

Our Custom Sheet Metal Fabrication Services

Our precision sheet metal services offer custom-made metal parts and components for various industries and applications. Prototek’s skilled engineers and technicians use advanced equipment and techniques to create precise, high-quality products from materials such as stainless steel, aluminum, copper, and titanium. Additionally, we can manufacture anything from simple brackets and enclosures to complex assemblies and structures. Furthermore, our services include design and engineering support, metal cutting, bending, punching, welding, painting, and finishing. Moreover, we provide rapid prototyping and low-volume production options to meet specific project needs. Most importantly, we deliver cost-effective, reliable solutions that meet our clients’ quality, performance, and turnaround time requirements. Whether it’s a one-off project or a production run, our team is ready to provide exceptional sheet metal fabrication services that exceed expectations.

Bending & Forming

OEM:

Amada and Birmingham

Lead Time:

1 -15 Days

Max Dimensions:

61 x 0.1345 in (10 Ga.)

Roll Length & Diameter: 4-3/4 in

(capacity based on Mild Steel)

Pinch Adjustment: Standard

Laser Cutting

OEM:

Amada, Beam Dynamics, Epilog, IPG

Lead Time:

1 -15 Days

Max Dimensions:

61 x 99 x 11.8 in

Waterjet Cutting

OEM:

Flow

Lead Time:

1 -15 Days

Max Dimensions:

Linear Straightness: ± 0.0021 in

Repeatability: 0.0014 in

Custom Sheet Metal Materials

Prototek provides an extensive selection of sheet metal fabrication materials, including aluminum, copper, stainless steel, titanium, and various alloys. We understand that each project may have unique requirements, and if you need a specific material or grade/alloy that is not listed, please don’t hesitate to reach out to our team. We are committed to working with you to fulfill your project’s material needs.

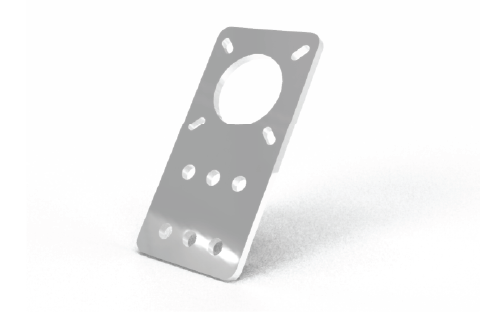

Aluminum

Sheet metal fabricated aluminum is a popular choice for many industries due to its durability, lightweight properties, and attractive appearance. As a result, aircraft, automobiles, appliances, and electronics construction use aluminum. The fabrication process allows for customization of the final product, ensuring that it meets the exact specifications of the customer. The end product is strong, malleable, and resists rust and corrosion, making it an ideal choice for many applications.

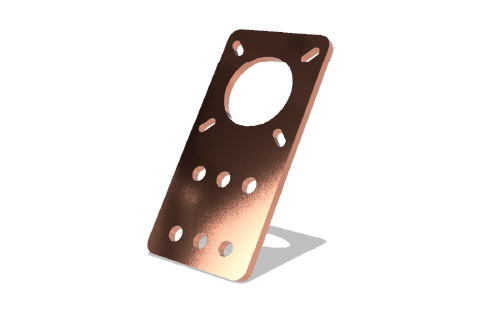

Copper

Sheet metal fabrication shapes and forms metals like copper sheets to create various products. Copper’s excellent ductility and malleability make it ideal for fabrication. Roofing, plumbing, electrical, and electronics often use copper. Our team cuts and shapes copper with specialized tools. Conversely, assembly, welding, and soldering are commonplace when creating copper components. Sheet metal fabricated copper has excellent thermal and electrical conductivity and is corrosion-resistant. It is suitable for multiple industries and applications.

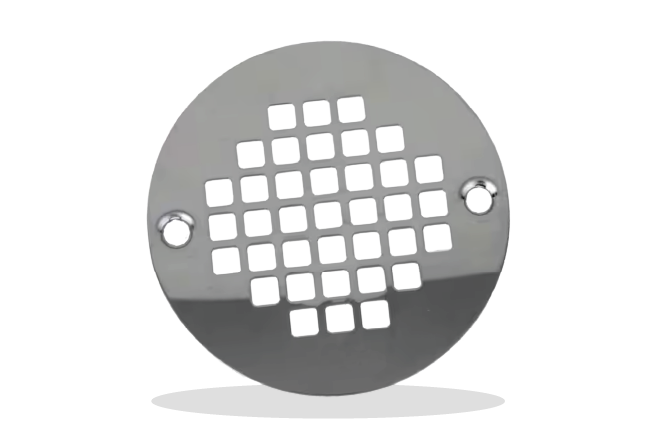

Stainless Steel

Stainless steel sheet metal is a durable and corrosion-resistant material widely used in various industries. It is created by adding chromium to steel, which forms a protective layer that prevents rust and other forms of corrosion. Additionally, the fabrication process involves cutting, bending, and welding a flat stainless steel sheet. Automotive parts, industrial equipment, and building components use stainless steel due to its low maintenance requirements and ability to withstand harsh environments and extreme temperatures. Furthermore, quality, versatility, and aesthetic appeal are qualities found in stainless steel.

Titanium

Sheet metal fabricated titanium is a popular material for sheet metal fabrication due to its excellent strength, corrosion resistance properties, and lightweight nature. The aerospace, military, medical, and industrial industries commonly use titanium in applications that require components with high strength-to-weight ratios. Additionally, titanium’s unique properties make it an ideal material for applications subject to high heat.

Sheet Metal Finishes

After cutting, bending, and forming sheet metal– finishing is the step in precision sheet metal fabrication because it determines the appearance and durability of the final product. Sheet metal fabricators may use various finishing techniques such as painting, powder coating, polishing, anodizing, or plating to provide additional protection against corrosion and wear. The chosen finishing technique depends on the metal product’s intended use and the designer’s aesthetic preferences. For example, a high-quality finish can enhance the product’s visual appeal and increase its value. Overall, finishing is crucial in creating a successful sheet metal fabrication project. Choosing a qualified and experienced sheet metal fabricator like Prototek can ensure the desired result is essential.

Precision Sheet Metal Fabrication FAQs

Sheet metal fabrication is the process of creating metal parts and products by cutting, bending, and forming thin sheets of metal. This versatile manufacturing technique allows for the production of a wide range of components, from simple brackets to complex enclosures. Prototek’s skilled team leverages advanced equipment and techniques to deliver high-quality sheet metal parts tailored to your specific requirements.

At Prototek, we offer a wide range of sheet metal finishing options to meet your specific requirements. Our capabilities include powder coating, plating, anodizing, and painting, ensuring a durable and visually appealing final product. Our team of experts will work closely with you to determine the optimal finish for your project, delivering high-quality results that exceed your expectations.

For several reasons, Prototek’s sheet metal fabrication services are ideal for manufacturing your project. Prototek has state-of-the-art equipment, advanced machinery, and talented sheet metal fabricators. Ensuring every project is produced with high precision and attention to detail and meets the highest quality standards. Secondly, our experienced team at Prototek comprises highly skilled engineers, designers, and sheet metal fabricators with expertise in various industries. We work with you through every step of the fabrication process, providing technical support as needed. Thirdly, Prototek is dedicated to providing cost-effective solutions to its clients and embraces constant innovation to ensure its services remain cutting-edge. Finally, we pride ourselves on its exceptional communication, having streamlined and efficient processes to deliver projects quickly and accurately. These reasons make us an excellent choice for manufacturing your metal fabrication project.

Sheet metal fabrication is precise, cost-effective, and versatile solutions for your manufacturing needs.

Sheet metal fabrication can be labor-intensive and limited design flexibility compared to other manufacturing methods.