Aerospace & Defense Manufacturing

Parts in days anywhere in the USA.

Our aerospace & defense manufacturing capabilities:

- Instant Quotes and Engineer Assisted Quotes

- 100+ Metal and Plastic Materials

- 40+ Surface Finishes

- Quality Prototypes and End-Use Parts

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team begins production once the project specifications are finalized and the quote is accepted.

When the part has been completed and finished, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

Don't just wing it - we're here to help!

Using additive manufacturing, CNC machining, and sheet metal fabrication to produce aerospace and defense components offers several advantages. Additive manufacturing enables the creation of intricate parts with reduced weight and material waste and improved structural integrity. Additionally, CNC machining ensures precise details with tight tolerances and efficient production of large batches. Moreover, sheet metal fabrication provides a cost-effective option for high-quality parts with minimal material waste. These methods are well-suited for rapid prototyping, allowing for quick design iterations and testing. By implementing these techniques, the aerospace and defense industries can achieve reduced lead times, increased efficiency, and optimized designs for better performance. Furthermore, additive manufacturing and CNC machining enable the production of unique, custom-designed parts, promoting functionality and innovation. These manufacturing techniques offer numerous benefits and underscore the importance of ongoing advancements in aerospace and defense manufacturing processes.

Quality Control for Aerospace & Defense

We offer top-of-the-line services tailored to the aerospace and defense industries. We take great pride in adhering to strict quality and safety standards, as evidenced by our facilities with certifications, including AS9100D and ISO 9001:2015. Additionally, we are ITAR-registered for US military projects. We have been registered with the US Department of State DDTC to import and export defense articles and services, as USML defines. We take great pride in our extensive range of capabilities and ability to provide custom solutions for each client.

Certifications & Registrations

Our commitment to unparalleled quality and safety standards is evident in our certifications, which include AS9100, ISO 9001, and ITAR.

Quality Documentation

Validation reports include CMM inspection, dimensional inspections, material tests, certificates of conformance, and first article inspections.

QC for Your Project

As a company that is dedicated to delivering top-quality products, we take our quality control process very seriously. We use specialized tools and equipment, perform dimensional checks using calibrated tools, maintain quality documentation, and hold industry certifications. Additionally, we protect our platform with IP protections.

Additive Manufacturing for Aerospace & Defense Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized the aerospace and defense industries by enabling the production of complex, customized parts and components. This innovative technology allows for the creation of intricate designs, reduced lead times, and the ability to manufacture parts on-demand, leading to significant advancements in these industries. Aerospace and defense companies are leveraging the benefits of additive manufacturing to develop lighter, more efficient aircraft and spacecraft and specialized equipment and tools for military applications. The flexibility and agility of this technology have empowered these industries to push the boundaries of innovation, driving the development of cutting-edge products and solutions.

A few aerospace and defense applications of additive manufacturing:

- Air Ducts

- Aircraft Interiors

- Brackets

- Drone Components

- Engine Components

- Nozzles

- Satellite Antena

- Space Vehicle Components

We offer Military Specification (MIL-spec) coatings, typical for SLS and FFF parts.

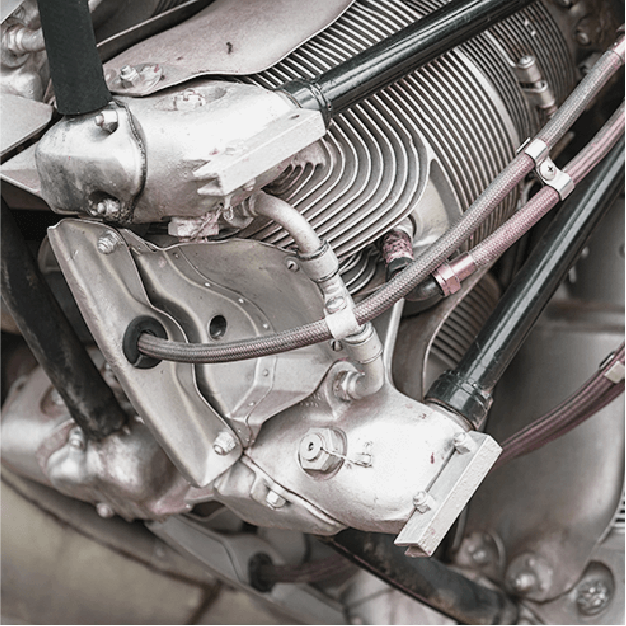

CNC Machining for Aerospace & Defense Manufacturing

CNC, which stands for Computer Numerical Control machining, is a highly advanced and automated manufacturing process used in various industries, especially aerospace and defense. This process involves using computer-controlled machines and CAD software to cut and shape raw materials into precise and efficient parts. Additionally, CNC machining allows engineers to create highly accurate and consistent components while reducing production costs and time. Moreover, this technology ensures that the finished products meet the quality and safety standards required for the aerospace and defense industries. Overall, CNC machining has revolutionized the manufacturing industry by providing a reliable and efficient method for creating complex and intricate designs.

A few aerospace and defense applications of CNC machining:

- Advanced Weapons Systems

- Electrical Instruments

- Engine Components

- Fuel Systems

- Hydraulic Systems

- Landing Gear

- Structural Components

- Turbine Blades

We offer Chemical Agent Resistant Coating (CARC), anodizing, passivization, electroplating, powder coating, and other finishes.

Sheet Metal Fabrication for Aerospace & Defense Manufacturing

The aerospace and defense industries extensively utilize sheet metal fabrication to manufacture various components. This process involves creating complex metal parts and structures from flat sheets of material. The sheets are cut, bent, and folded into the desired shape. Sheet metal fabrication creates diverse products in these industries, including frames, covers, doors, aircraft wings, engine components, and other complex structures.

Moreover, the aerospace and defense industries prefer sheet metal fabrication because it is a cost-effective solution that can handle high volumes and a wide array of material thicknesses. Additionally, the process allows for producing complex geometries with tight tolerances and accurate precision. As these industries require high durability, strength, and corrosion resistance, sheet metal fabrication is ideal for meeting these requirements due to its inherent characteristics. Overall, sheet metal fabrication remains a critical process in manufacturing components for the aerospace and defense industries.

A few aerospace and defense applications of sheet metal fabrication:

- Aircraft Panels

- Control Surfaces

- Engine Components

- Fuselages

- Turbine Blades

- Wings

We offer Chemical Agent Resistant Coating (CARC) as well as anodizing, passivization, electroplating, and powder coating as well as other finishes.

Additional Manufacturing Capabilities

3D scanning is widely used in aerospace and defense for reverse engineering, quality control, and dimensional inspection. It creates detailed models of aircraft components, aiding in analysis and improving design. Additionally, it inspects parts for defects or damage to ensure safety, compliance with regulations, and efficient maintenance and repair.

Injection molding plays a pivotal role in the aerospace and defense industry as it is employed to produce components that require an exceptional level of accuracy and precision. The method of injecting melted materials into a mold cavity enables the creation of intricate shapes and geometries that would otherwise be impossible to achieve through other manufacturing processes. This technique is highly valued for its ability to produce superior quality and reliability components, making it an indispensable tool in the aerospace and defense industry.

A few aerospace and defense applications of 3D scanning and injection molding:

- Bezels

- Enclosures

- Interior & Exterior Components

- Panels

- Quality Control

- Reverse Engineering

Why choose Prototek to manufacture your aerospace & defense manufacturing project?

Prototek specializes in providing top-quality manufacturing services to the aerospace and defense industries. With decades of experience, we have honed our skills in additive manufacturing, CNC machining, and sheet metal fabrication. Our expertise has been tested on numerous high-profile projects in the aerospace industry, earning us an impeccable reputation as a reliable and trusted manufacturer. In addition to our extensive experience, quality is paramount in everything we do. That’s why we have obtained the prestigious ISO 9001:2015 and AS9100D certifications and ITAR Registration, demonstrating our unwavering commitment to providing unparalleled quality to our clients and serving as a testament to our dedication to constant improvement. When you choose us for your manufacturing needs, you can rest assured that you’re getting top-notch services delivered by a team of passionate experts.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.