Machining Services:

Wire & Sinker EDM

Parts in days anywhere in the USA.

Our Wire & Sinker EDM services offer:

- Repeatability

- High Dimensional Tolerances

- Custom Prototypes and End-Use Parts

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team starts production after finalizing project specifications and accepting the quote with you.

When the part has been completed and finished, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

What is wire and sinker EDM?

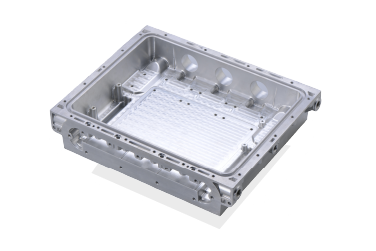

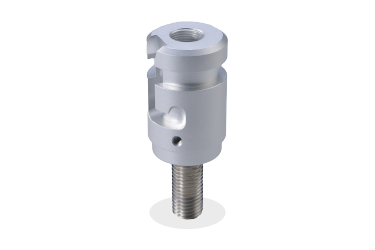

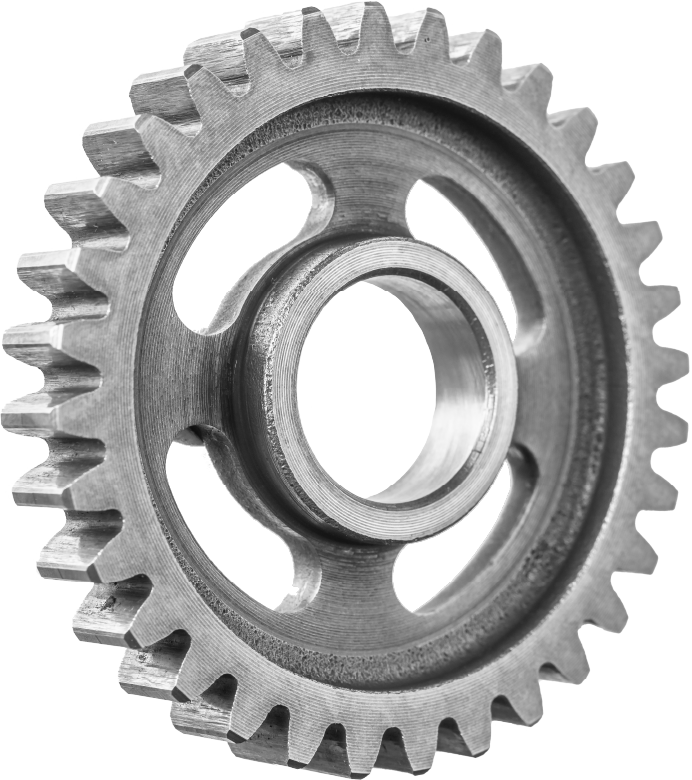

Wire EDM and sinker EDM are machining processes commonly used to cut complex shapes and patterns into hard metals. A thin metal wire creates the cuts in wire EDM, whereas sinker EDM uses an electrode shaped like the desired cut. In both processes, an electrical discharge is passed between the metal blank and the cutting tool, causing the metal to erode in small particles. As a result, this process allows for precise cuts and intricate shapes that would be difficult or impossible to create with traditional machining methods. Wire EDM machining cuts thin or delicate parts. In contrast, sinker EDM machining commonly manufactures molds or dies. Moreover, industries such as aerospace, automotive, medical devices, and precision engineering use both methods.

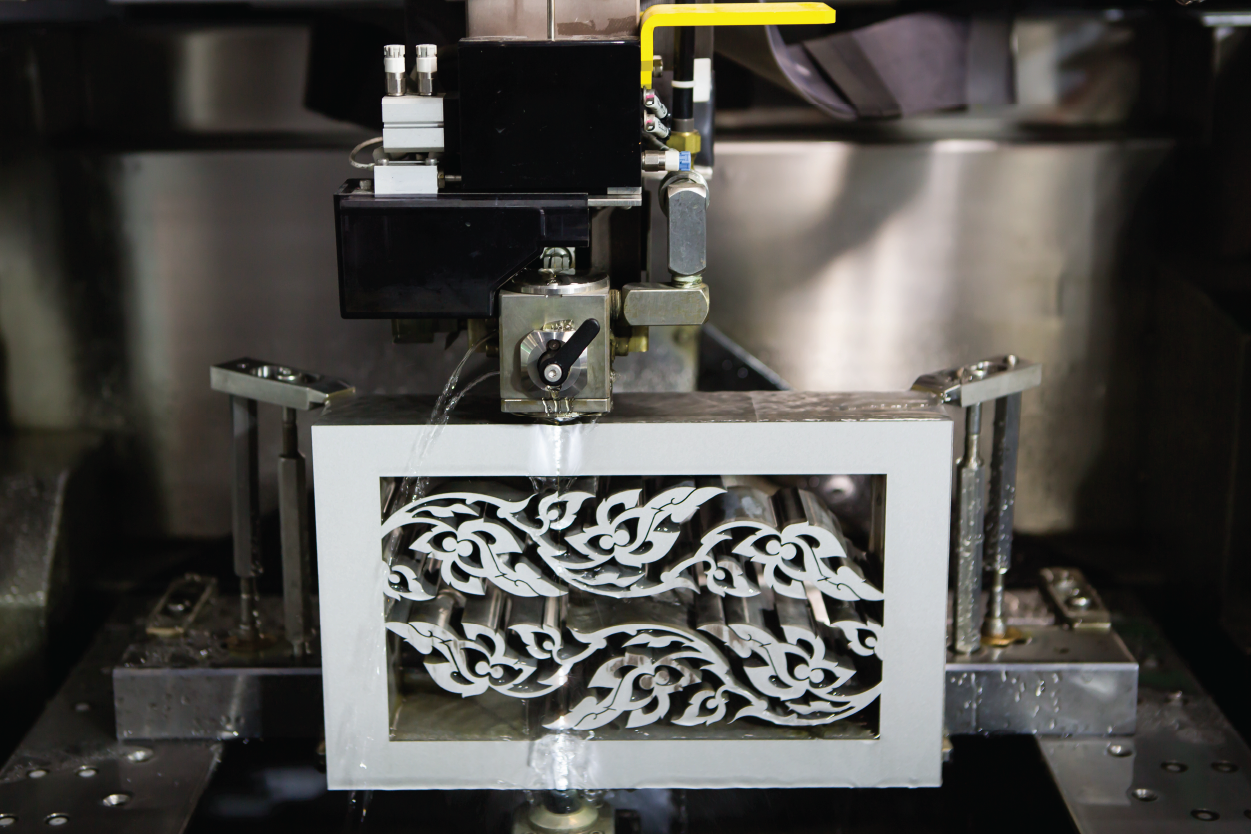

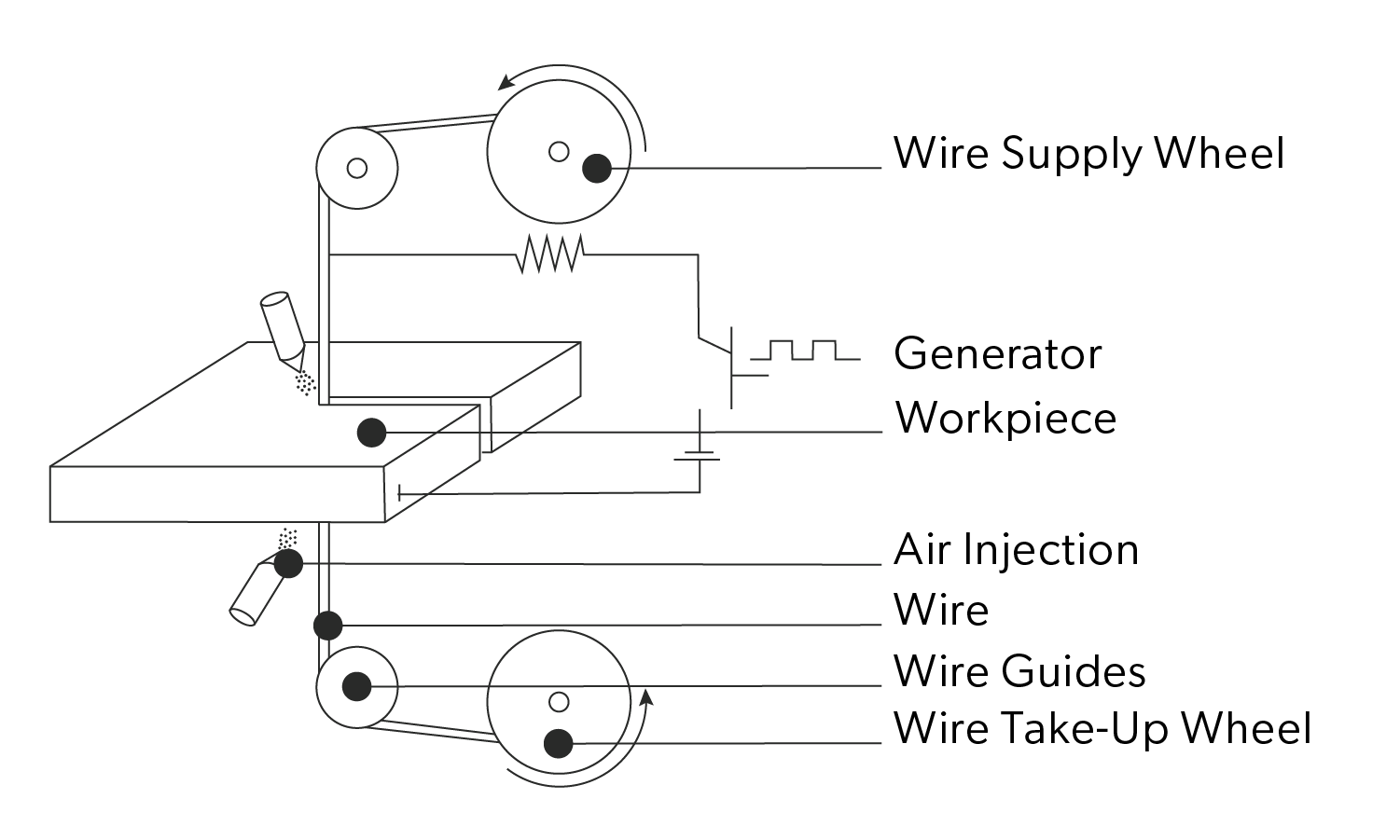

How does wire EDM work?

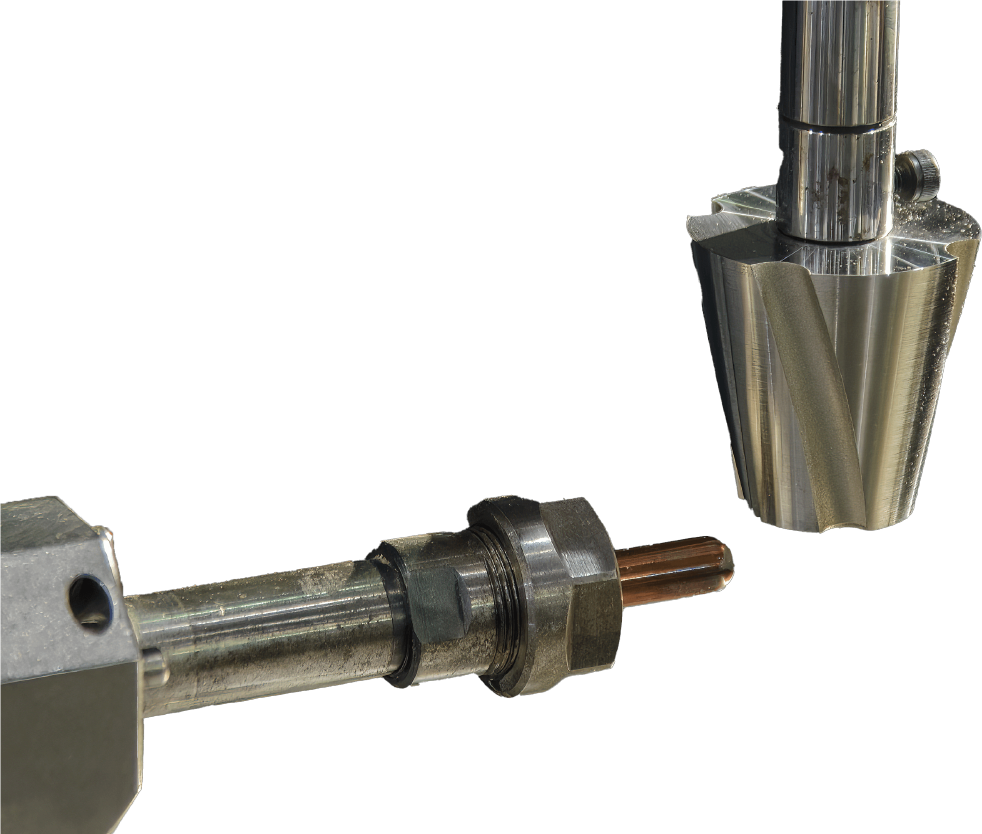

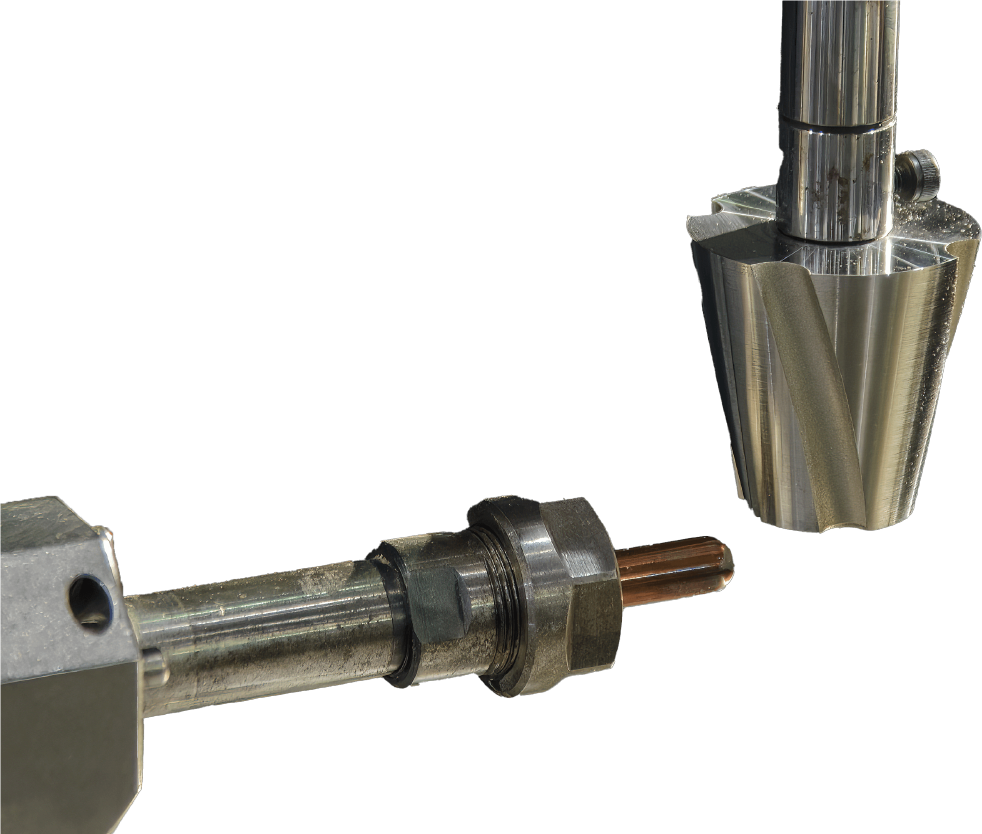

Wire EDM, or Electrical Discharge Machining, is an exact process that utilizes electrical energy to cut through hard materials. It involves a thin, electrically charged wire that creates precise cuts through electrically conductive materials such as metal work pieces. Throughout the process, applying an electrical discharge to the wire generates a spark that melts the surface of the workpiece. A dielectric fluid circling the cutting area flushes away the melted material. As the wire electrode continuously moves, it makes electrical discharges, creating a path and forming the shape of the desired final product. Due to its high precision and accuracy, wire EDM machines are fantastic for industries that demand tight tolerances, such as aerospace, medical, and automotive applications.

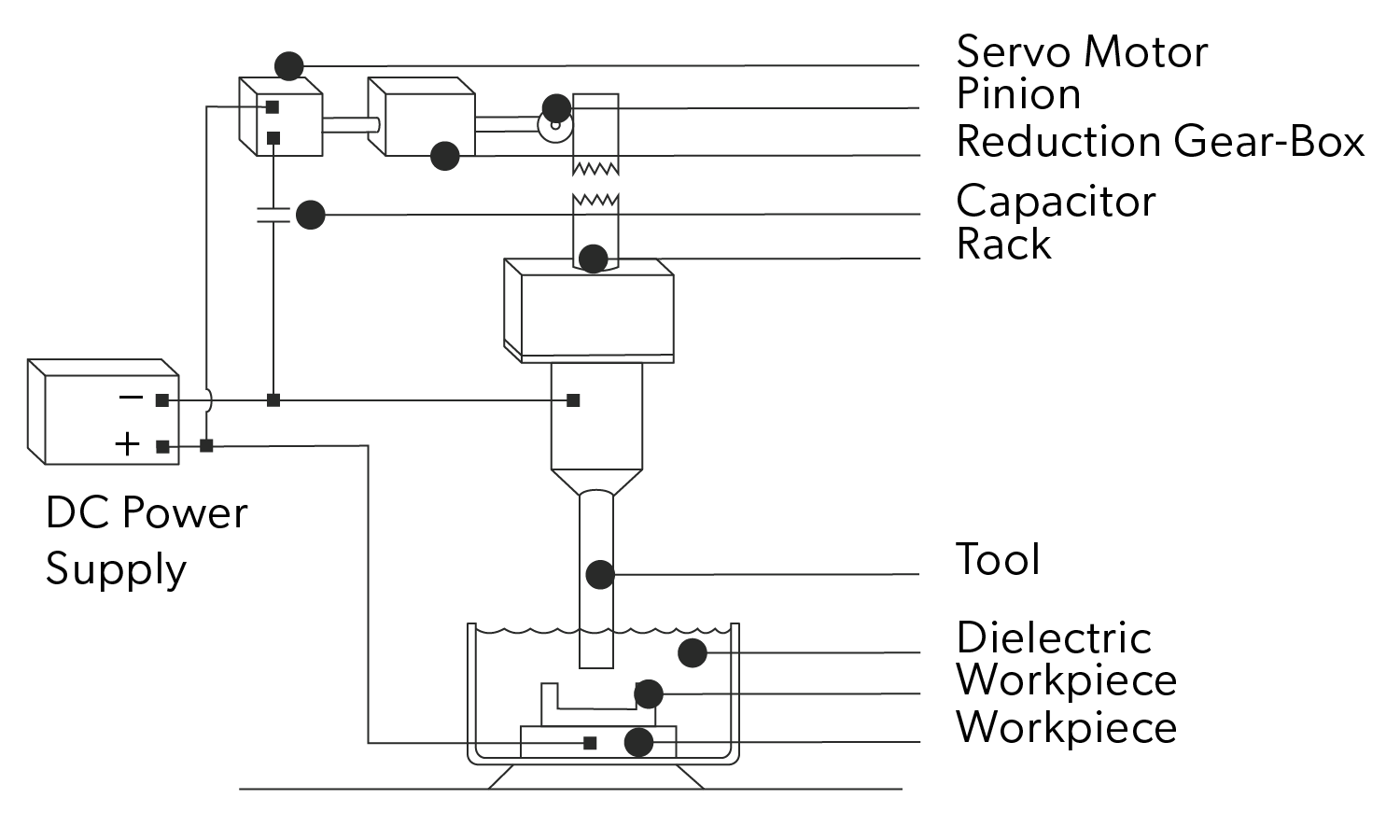

How does sinker EDM work?

Sinker EDM (Electrical Discharge Machining) is a manufacturing process in which a shaped electrode (typically made of graphite or copper) submerges a workpiece in an electrically conductive fluid. A controlled electrical charge passes between the two, creating sparks as the electrode approaches the workpiece and melting the material on its surface. Subsequently, the fluid flushes the melted material away, allowing the electrode to contour the design’s shape – repeating this process until the part is complete.

The electrical charge used is very high, but it only lasts briefly. Furthermore, the process requires precise control, as the electrical discharge can damage the workpiece, and repetition is needed to achieve the required shape. Sinker EDM machines are standard in creating tools, dies, and molds for the automotive, aeronautical, and medical industries.

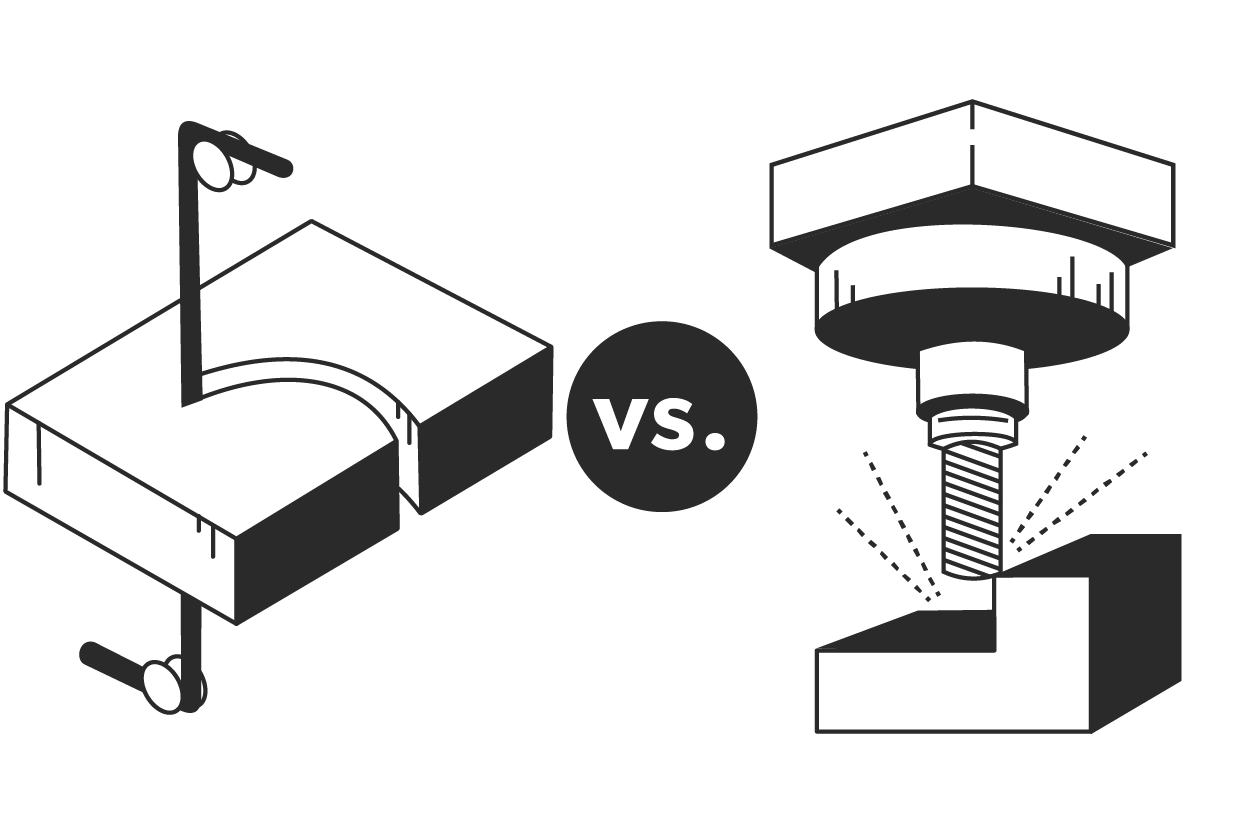

What is the difference between Wire & Sinker EDM?

Wire EDM and sinker EDM are two types of Electrical Discharge Machining processes. The main difference is that wire EDM uses a thin wire as the electrode to cut through the workpiece, while sinker EDM uses a shaped electrode to create the desired shape in the workpiece. Wire EDM cuts intricate shapes or parts with tight tolerances; sinker EDM is better suited for creating deeper cavities and shapes in larger workpieces. Another key difference is that wire EDM keeps a constant gap between the electrode and the workpiece. In contrast, sinker EDM submerges the electrode in a dielectric fluid to cool and flush away debris. Both processes have advantages and limitations. Choosing between them depends on the job’s requirements.

EDM at Prototek

OEM:

Fanuc and Sodick

Lead Time:

5 – 22 Days

Max Dimensions:

31.5 x 23.6 x 31.5 in thick

Material:

Aluminum, Inconel, Stainless Steel and Steel, Titanium, and Other Materials

Prototek's Materials

Metals

- Aluminum

- Brass

- Bronze

- Copper

- Nickel Based High Temperature Alloys:

- Inconel

- Invar

- Kovar

- Nitronic 60

- Stainless Steel

- Steel

- Titanium

- Tool Steel

Plastics

- ABS

- Acrylic

- Acetal

- HDPE

- Nylon

- PEEK

- Polycarbonate

- Polypropylene

- Teflon/PTFE

- ULTEM

Other Materials

- G-10

- Machined Ceramics:

- Macor

- Wood

Does your project require a material not on our list?

Let us know if your project requires materials that are not on the list! We can accommodate other material requests, but quotes may need more time while we source the material.

Wire & Sinker EDM Finishes

Wire EDM and sinker EDM are standard methods for creating precise cuts and finishes on metal parts. In wire EDM, a thin wire carries an electrical current that burns through the material and creates a cut or shape, making it ideal for intricate designs where accuracy is crucial. On the other hand, sinker EDM involves submerging an electrode in a bath of dielectric fluid to create an electrical current that erodes the material. This process produces highly polished surface finishes, particularly on parts with complex shapes or tricky angles. Wire and sinker EDM produces high-quality results but has unique strengths and weaknesses. Therefore, the choice between wire and sinker EDM depends on the specific needs of a project and the desired finish.

Electric Discharge Machining vs Conventional Machining

Electric Discharge Machining (EDM) and conventional machining are two different manufacturing processes with advantages and applications. EDM uses electrical discharges to erode material, making it suitable for intricate and complex geometries. In contrast, conventional machining relies on mechanical tools to remove material, offering a more versatile approach for a wide range of part sizes and materials. When choosing the correct manufacturing method, factors such as part complexity, material properties, and production requirements should be carefully considered to ensure the best solution for your project.

Contact our team if you have questions about the best options for your project!

Prototek's

Other CNC Manufacturing Capabilities

Why choose Prototek for your wire and sinker EDM project?

Prototek is a trusted and reliable wire and sinker EDM service provider that delivers high-quality results. Our experienced technicians use state-of-the-art equipment and tools to create precise cuts, ensuring the end product meets the required specifications. We also offer a quick turnaround time, which allows you to stay on schedule and complete projects on time. Prototek understands that each project is unique and offers customized solutions that meet your needs, whether a prototype or low to high-volume production. Our team is dedicated to meeting your requirements and providing exceptional customer service. Prototek’s commitment to quality and customer satisfaction makes them the top choice for your project.