Machining Service:

CNC Routing Parts

Our high-precision CNC routing services offer the following:

- Repeatability

- High Dimensional Tolerances

- Custom Prototypes and End-Use Parts

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

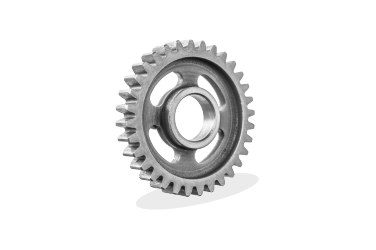

What is CNC Routing?

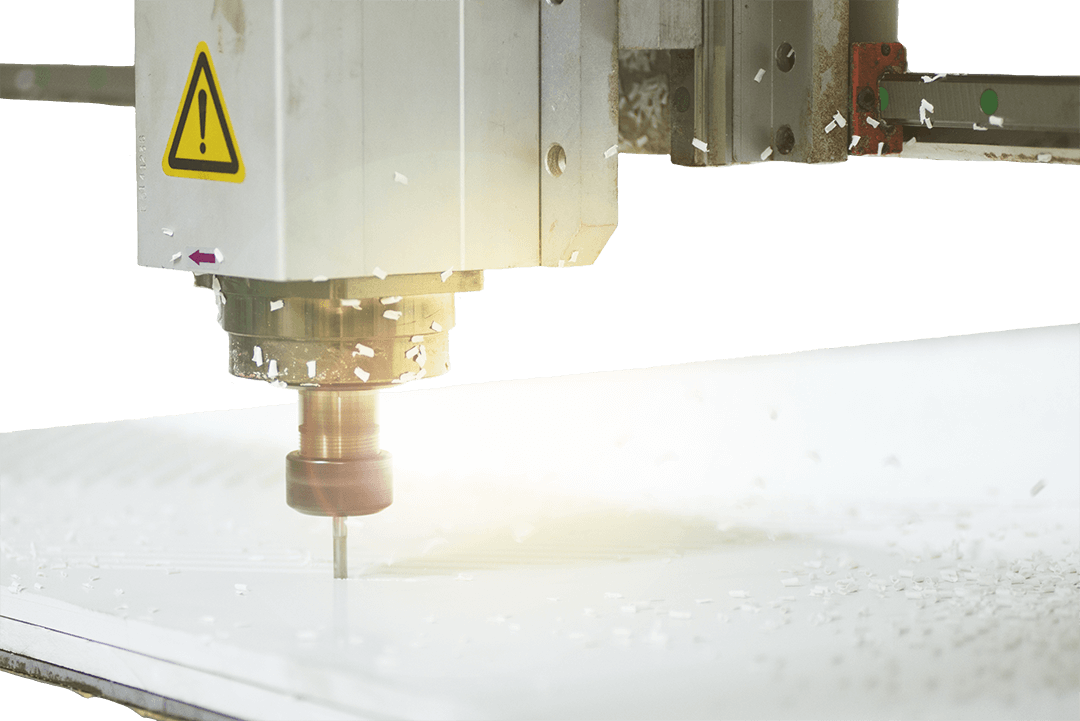

CNC (Computer Numerical Control) routing is an innovative manufacturing process that utilizes computer-controlled cutting tools to precisely shape and carve various materials, including wood, plastics, and metals. This cutting-edge technology empowers us to create highly detailed designs, intricate geometries, and custom parts with exceptional accuracy and efficiency. By harnessing the power of CNC routing at Prototek, we can actualize and refine your groundbreaking concepts, producing top-quality components that meet and exceed the most stringent specifications.

How does CNC Routing work?

CNC routing uses computer-controlled machines to cut and carve wood, plastic, and metal. Technicians position the material on the machine bed, and a cutting tool follows programmed paths to shape the material. It is efficient, precise, and commonly used for creating furniture, cabinetry, signage, and industrial parts.

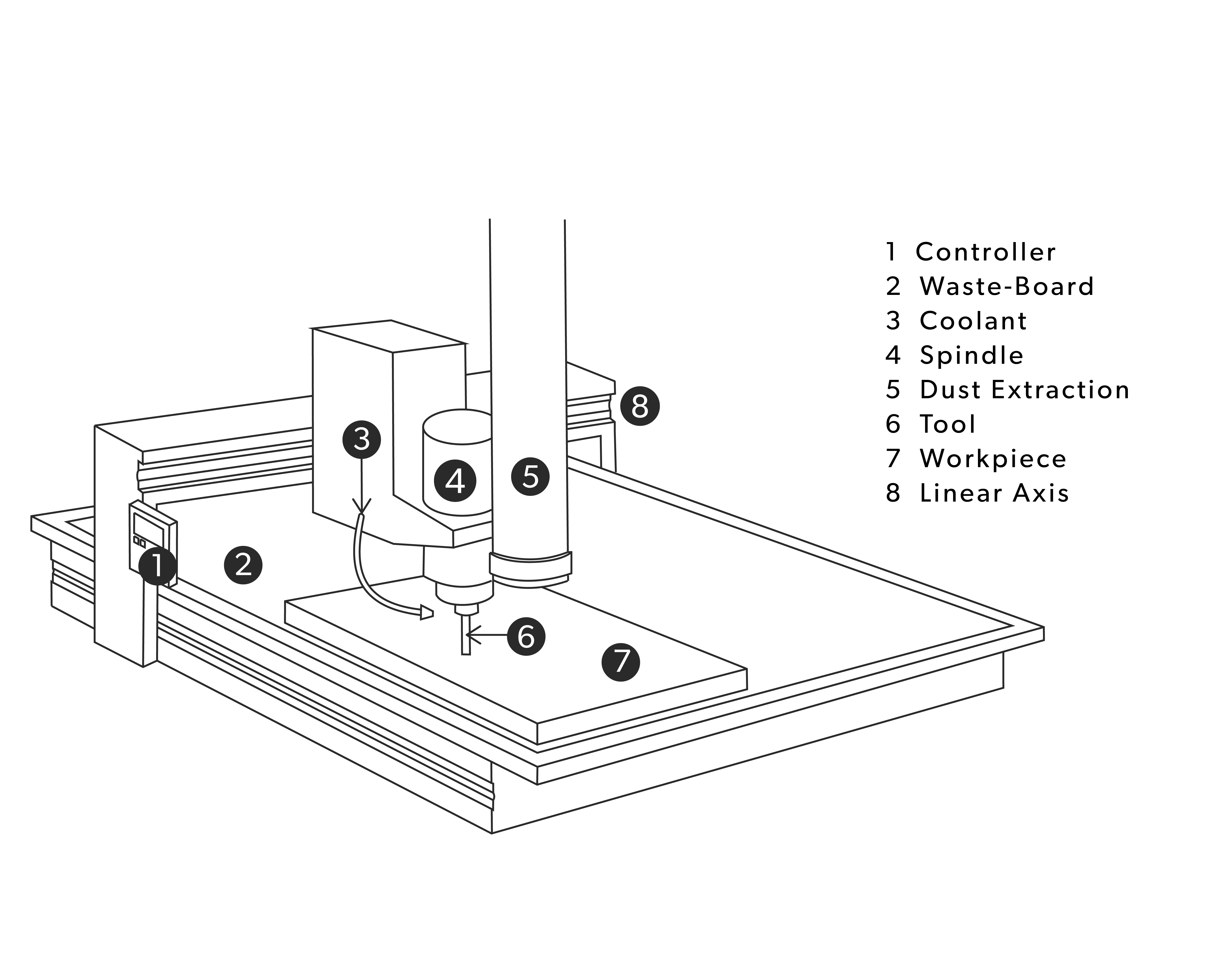

What are the parts of a router?

A CNC (Computer Numerical Control) router is a versatile machine tool that uses computer-controlled motors to precisely cut, shape, and carve various materials, such as wood, plastic, and metal. The main components of a CNC router typically include:

1. Frame: The sturdy frame provides structural support for the entire machine and ensures stability during operation.

2. Spindle: The spindle is the rotating tool holder that securely grips the cutting tool or bit and spins it at high speeds to perform the cutting or engraving.

3. Axes: CNC routers typically have three primary axes (X, Y, and Z) that allow the spindle to move in multiple directions, enabling complex cutting patterns and shapes.

4. Motors and Drives: Powerful motors, often stepper or servo motors, control the movement of the axes, precisely positioning the spindle as per the programmed instructions.

5. Controller: The computer-based controller is the “brain” of the CNC router. It interprets the G-code or CAM (Computer-Aided Manufacturing) software instructions and sends the appropriate signals to the motors and drives.

6. Cutting Tools: Various specialized cutting tools, such as end mills, drill bits, and router bits, are used to cut, shape, and engrave the workpiece material.

7. Workholding: The workpiece is securely placed on the machine’s table or bed, often using clamps, vises, or vacuum systems, to ensure accurate and consistent cutting.

CNC Routing Advantages

CNC routing has revolutionized the way products are designed and manufactured. The following are a few of the advantages of CNC routing:

- Precision & Accuracy - Programmable to tight tolerances.

- Volume - Great for higher volume repetitive parts.

- Versatility - Wide range of materials: wood, plastics, metals, and composites.

CNC Routing Disadvantages

While there are a lot of advantages to routing, there are also some disadvantages to consider:

- Size Limitations - Limited to size of of machine.

- Hard Metals - Can't machine metals such as titanium and steel.

CNC Routing at Prototek

OEM:

KOMO

Lead Time:

14 Days

Max Dimensions:

48 x 120 in

Material:

Plastic, composites, wood, soft metals.

Tolerances:

± 0.005 in

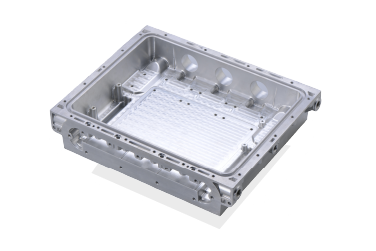

Prototek's Machining Materials

At Prototek Digital Manufacturing, we specialize in a wide range of CNC routing materials to meet the diverse needs of our clients. From high-performance plastics and advanced composites to wood and metal, our state-of-the-art CNC routers can precisely machine a variety of materials with unparalleled accuracy and efficiency. Whether you require intricate prototypes, functional parts, or custom-designed components, our skilled team has the expertise to bring your vision to life using the optimal CNC routing materials for your project.

Metals

Plastics

Other Materials

- G-10

- Machined Ceramics:

- Macor

- Wood

Does your project require a material not on our list?

Let us know if your project requires materials that are not on the list! We can accommodate other material requests, but quotes may need more time while we source the material.

Designing Parts for Routing

When designing parts for a CNC router, several essential factors must be remembered for the best results. Make sure your part’s shape works well with the CNC routing capabilities, such as having smooth curves, rounded corners, and avoiding sharp internal angles. Include proper clearances and tolerances to accommodate the router bit size and the machining process. Pay attention to the direction of the grain and material properties, as they can affect the quality of the finished part. Also, consider the tool paths and machining strategies to reduce waste, improve cycle times, and achieve a high-quality surface finish. By carefully designing your parts, you can take advantage of the speed and precision of CNC routing to bring your ideas to reality.

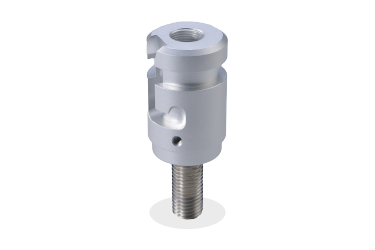

Finishes for Machined Components

At Prototek, we provide various finishing options for parts produced using our state-of-the-art CNC routers. Our skilled technicians can assist you in achieving the perfect finish for your project, whether you need precision machining, custom coatings, a smooth, polished surface, or a specialized texture. With our expertise and advanced equipment, you can trust Prototek to enhance the quality and appearance of your CNC-machined parts.

Learn More About CNC Machining

Through our resources, you can discover the complexities of CNC Machining and gain insights into creating top-notch designs specifically tailored for this cutting-edge technology.

Composite Materials: Innovations Shaping the Future

Composite materials are transforming industries with strength, lightweight nature, and design flexibility, particularly in aerospace and renewable energy. Advancements like nanocomposites and 3D printing enhance...

Advancements in Manufacturing Technologies for Shipbuilding

The manufacturing of parts for ships is a crucial aspect of the maritime industry. This process involves various methods, materials, and technologies to ensure that...

CNC Machining: Plastic Materials

As industries increasingly demand precision and versatility, our advanced capabilities can turn your ideas into reality. From lightweight and corrosion-resistant acrylic to durable polycarbonate and...

Prototek's

Other CNC Manufacturing Capabilities

Why choose Prototek for your next CNC routing project?

Choose Prototek for your next CNC manufacturing routing project and enjoy the benefits of more than 30 years of experience in providing top-quality precision machined parts and assemblies. Our team of experienced engineers and machinists is dedicated to providing exceptional service. We use state-of-the-art CNC equipment and software to produce high-quality components that meet specifications. We offer in-house services, including CNC routing, milling, turning, and sheet metal fabrication. This means faster turnaround times and lower costs for you. Partner with Prototek for your next CNC routing project; we will provide only the highest quality parts and services.