Additive Manufacturing

Services at Prototek

Parts in days anywhere in the USA.

Prototek’s additive manufacturing offers:

- Production-Grade Materials

- Price Breaks on Large-Volume Orders

- Precision & Repeatability

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team begins production once the project specifications are finalized and the quote is accepted.

When the part has been completed and finished, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

Our Additive Manufacturing Services

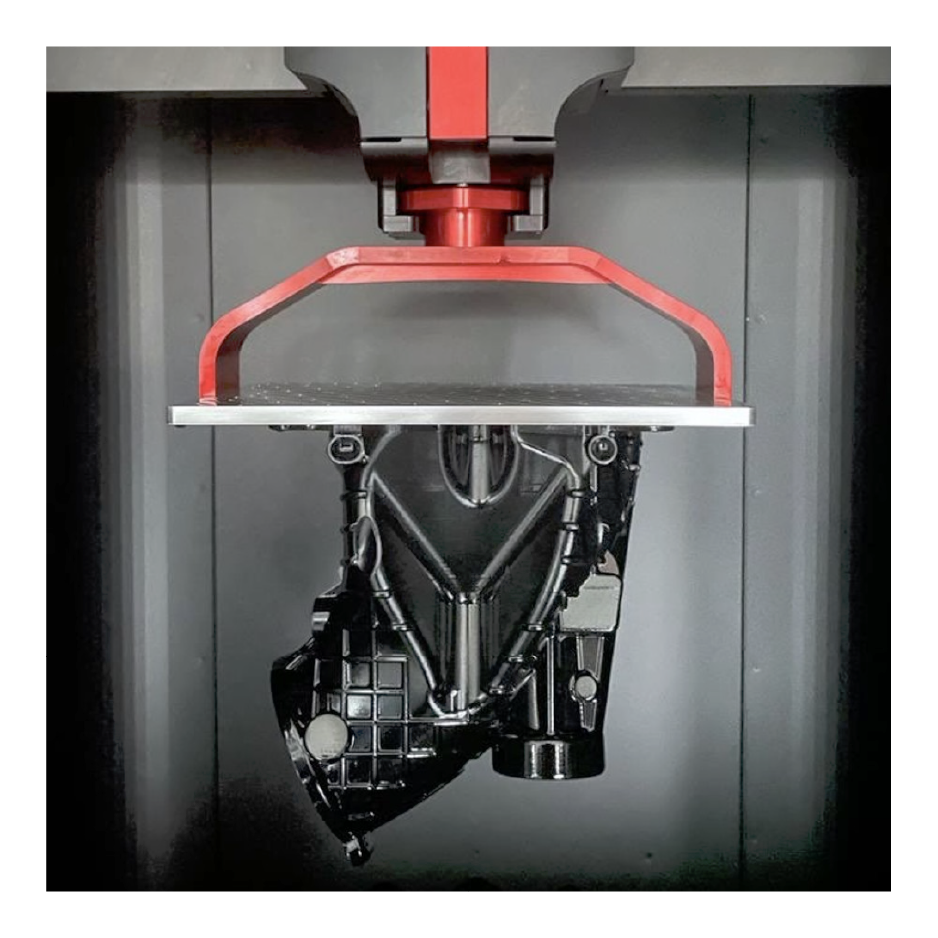

Prototek is a leading provider of additive manufacturing services for customers across various industries. By leveraging state-of-the-art 3D printing technology, Prototek can create highly detailed and precise end-use parts and prototypes quickly and efficiently. Moreover, their team of experts offers a wide range of services, including design input, prototyping, and full-scale production. Additionally, with the ability to work with various materials, Prototek can produce parts with complex geometries and a wide range of sizes and shapes. Furthermore, they provide post-processing services such as finishing, painting, and assembly. Committed to quality and customer satisfaction, Prototek is the top choice for those seeking superior additive manufacturing services.

Laser Sintering

OEM:

EOS and 3D Systems

Lead Time:

3 – 5 Days

Max Build Area:

26 x 13.5 x 21.8 in

Tolerances:

First Inch ± 0.005 in

Add. Inches ± 0.002 in

Multi-Jet Fusion

OEM:

HP

Lead Time:

2 – 4 Days

Max Build Area:

14.96 x 11.18 x 14.96 in

Tolerances:

First Inch ± 0.010 in

Add. Inches ± 0.002 in

Stereolithography

OEM:

3D Systems and Stratasys

Lead Time:

1 – 3 Days

Max Build Area:

31 x 31 x 23 in

Tolerances:

First Inch ± 0.005 in

Add. Inches ± 0.0015 in

Digital Light Processing

OEM:

3D Systems and Stratasys

Lead Time:

1 – 2 Days

Max Build Area:

7.4 x 4.6 x 12.8 in

Tolerances:

Depends on the parts geometries.

Hybrid PhotoSynthesis

OEM:

Axtra3D

Lead Time:

3 – 5 Days

Max Build Area:

9.5 x 5.25 x 19.25 in

Tolerances:

First Inch ± 0.005 in

Add. Inches ± 0.0015 in

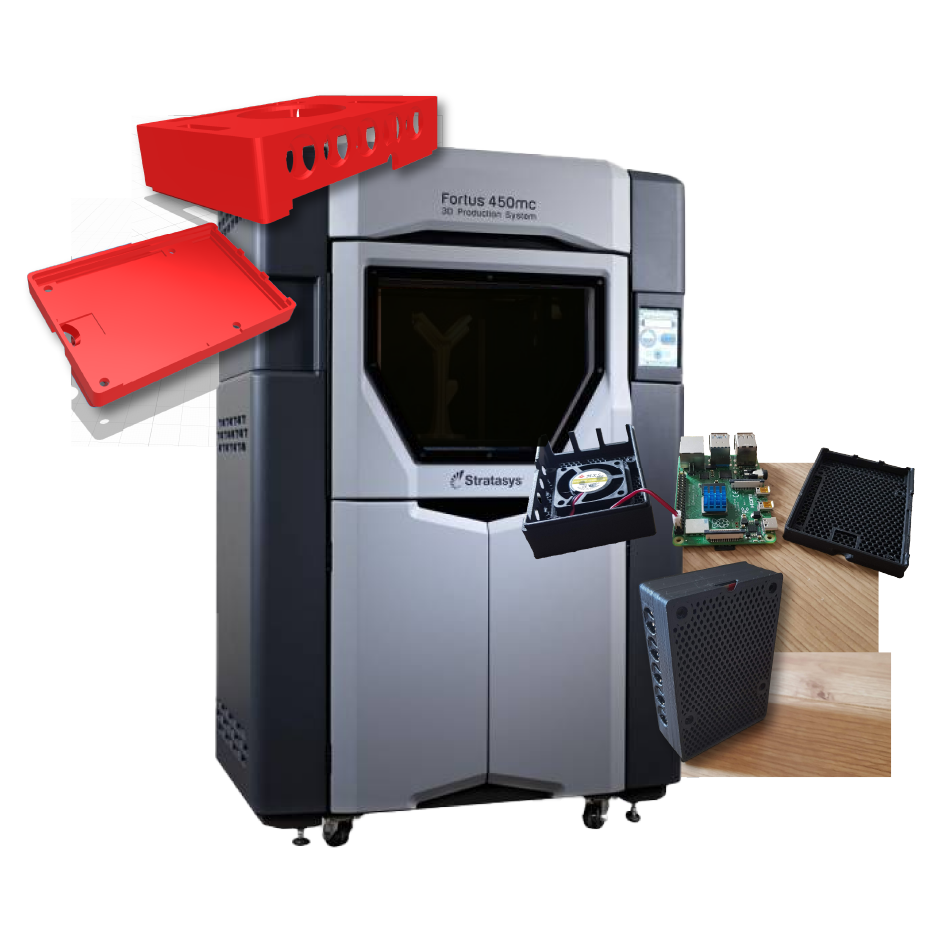

Fused Filament Fabrication

OEM:

Stratasys

Lead Time:

1 – 5 Days

Max Build Area:

36 x 24 x 36 in

Tolerances:

First Inch ± 0.005 in

Add. Inches ± 0.002 in

Material Jetting

OEM:

Stratasys

Lead Time:

1 – 2 Days

Max Build Area:

19.3 x 15.4 x 7.9 in

Tolerances:

First Inch ± 0.004 in

Add. Inches ± 0.0015 in

Additive Manufacturing Materials

Prototek is a leading supplier of thermoplastics explicitly designed for additive manufacturing. We offer an extensive selection of over 40 different types of thermoplastics, each with unique properties and advantages. Our range includes popular materials such as ABS, nylon, polycarbonate, and more specialized materials like Ultracur3D 3280 and Ultem.

Our thermoplastics are carefully selected and tested for the highest quality and consistency. We work with some of the industry’s most reputable manufacturers to source the best materials. Our team of experts is always available to assist you in selecting the most suitable material for your project needs.

Choosing the suitable material for your project requires careful consideration of several factors. The material’s mechanical properties, including strength, flexibility, and toughness, are essential in determining its ability to withstand physical stress. Chemical resistance is another crucial factor to consider, as the material should be able to endure exposure to chemicals like acids, bases, and solvents. Cost is also an essential factor, as some materials can be more expensive than others and can impact the overall cost of the finished product. Evaluating these factors thoroughly before selecting the appropriate material for 3D printing is vital.

Additive Manufacturing Finishes

When selecting finishes for additive manufacturing, it’s essential to consider several factors. Firstly, consider the intended use of the finished product, as this will determine the required durability and surface finish. Additionally, the chosen material will impact the available finishes, so selecting a material compatible with the desired finish is crucial. Moreover, some standard finishes for additive manufacturing include bead blasting, polishing, painting, and clear coating. It’s also important to consider each finish’s cost and lead time; for instance, more complex finishes generally require more time and resources. Ultimately, the chosen finish should be suitable for the intended use and enhance the product’s value rather than detract from it.

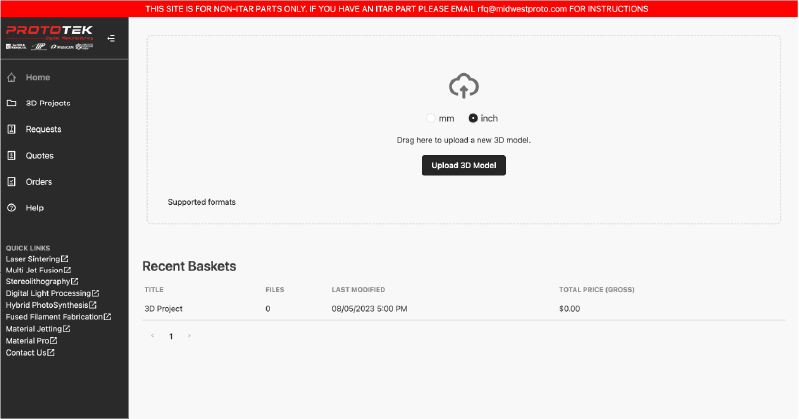

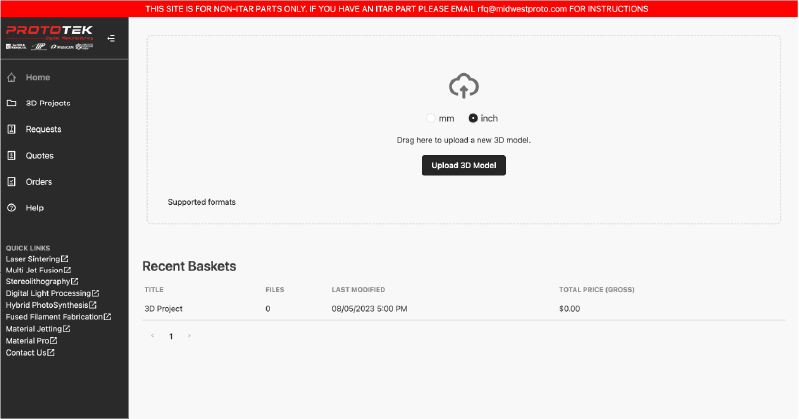

Prototek's AM Instant Quoting

Our top priority is simplifying your life by offering you a user-friendly experience while uploading your 3D model. The platform is a highly intuitive and straightforward system allows you to upload your creations with the utmost ease and speed. Prototek’s platform is user-friendly, and our instant pricing is a standout feature, enabling you to receive accurate and detailed project information in a snap.

- Get instant pricing.

- Lead times.

- DFM feedback for your 3D model.

Why choose Prototek's additive manufacturing to manufacture your project?

Several compelling reasons exist for choosing Prototek’s additive manufacturing for your project. First and foremost, our expertise and experience in the industry ensure that your project will be executed with precision and accuracy. Additionally, we utilize state-of-the-art equipment and cutting-edge technology to provide high-quality products. This includes various materials and finishes to ensure your project is made to your specifications. Furthermore, Prototek can produce complex and intricate designs that are impossible with other manufacturing methods. Moreover, our fast turnaround times and competitive pricing make us a cost-effective choice for small and large-volume production. With our unwavering commitment to quality and customer satisfaction, Prototek’s additive manufacturing is a reliable and trusted option for bringing your project to life.