Casting Services:

Injection Molding

Prototek’s 3D Scanning service offers:

- Reverse Engineered Parts

- Creating 3D CAD Files

- Quality Control

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

What is 3D scanning?

3D scanning involves capturing the 3D data of an object or environment using specialized equipment to create a precise digital image. This process includes emitting light or other electromagnetic radiation and measuring its reflection or absorption to produce a 3D representation of the object or space. The resulting data can be stored as a point cloud, which can then be used to generate 3D models for analysis, visualization, or engineering applications. Moreover, 3D scanning has many applications, including product design, reverse engineering, quality control, cultural heritage preservation, and medical imaging. It helps create accurate digital models of physical objects that can be modified, reproduced, or visualized digitally. Additionally, the technology continuously evolves, becoming more accessible and cost-effective, leading to broader adoption in various industries.

How does 3D scanning work?

Laser 3D scanning involves using a laser to emit a beam of light onto an object to measure its shape and geometry. Subsequently, the laser moves in a specific pattern across the object’s surface, capturing millions of data points through the reflection of the laser light. Sensors measure the time it takes for the laser light to bounce back from the object, allowing for the creation of a highly detailed 3D model of the object’s surface. This scanning process generates a cloud of data points that can be processed using specialized software to produce a 3D model file. The resulting 3D model has various applications, including 3D printing, reverse engineering, quality control, and inspection. Laser 3D scanning is a precise and reliable technology that provides accurate, high-resolution models, making it a valuable tool in many industries.

Reverse Engineering

Laser 3D scanning enables the detailed geometry of a physical object to be captured and transformed into a 3D digital model. This process, reverse engineering, is commonly used in automotive, aerospace, and product design industries. It is beneficial when the original design data is unavailable or requires updating.

Moreover, engineers can create accurate and detailed digital models that can replicate or enhance existing designs. By digitally capturing a physical object’s precise shape and surface information, engineers can utilize the data to design new parts or updates that can be easily manufactured.

Additionally, this technique is a vital tool for reverse engineering, as it facilitates precise, efficient, and cost-effective redesign and re-manufacturing of parts and components.

Quality Control

Laser 3D scanning is an increasingly popular technology for quality control applications across various industries. This technology provides a highly accurate and efficient method for measuring and inspecting complex objects, including their shape, size, and surface details. Unlike traditional measurement techniques, which can be time-consuming, subjective, and prone to errors, 3D scanning offers more reliable and repeatable measurement data. Additionally, it can be performed non-destructively, making it particularly useful for inspecting fragile or expensive parts. Moreover, industries that benefit from 3D scanning services for quality control include aerospace, automotive, medical devices, and consumer goods. Adopting 3D scanning in quality control can lead to improved product performance, reduced defects, and increased customer satisfaction.

Prototek's Services

OEM:

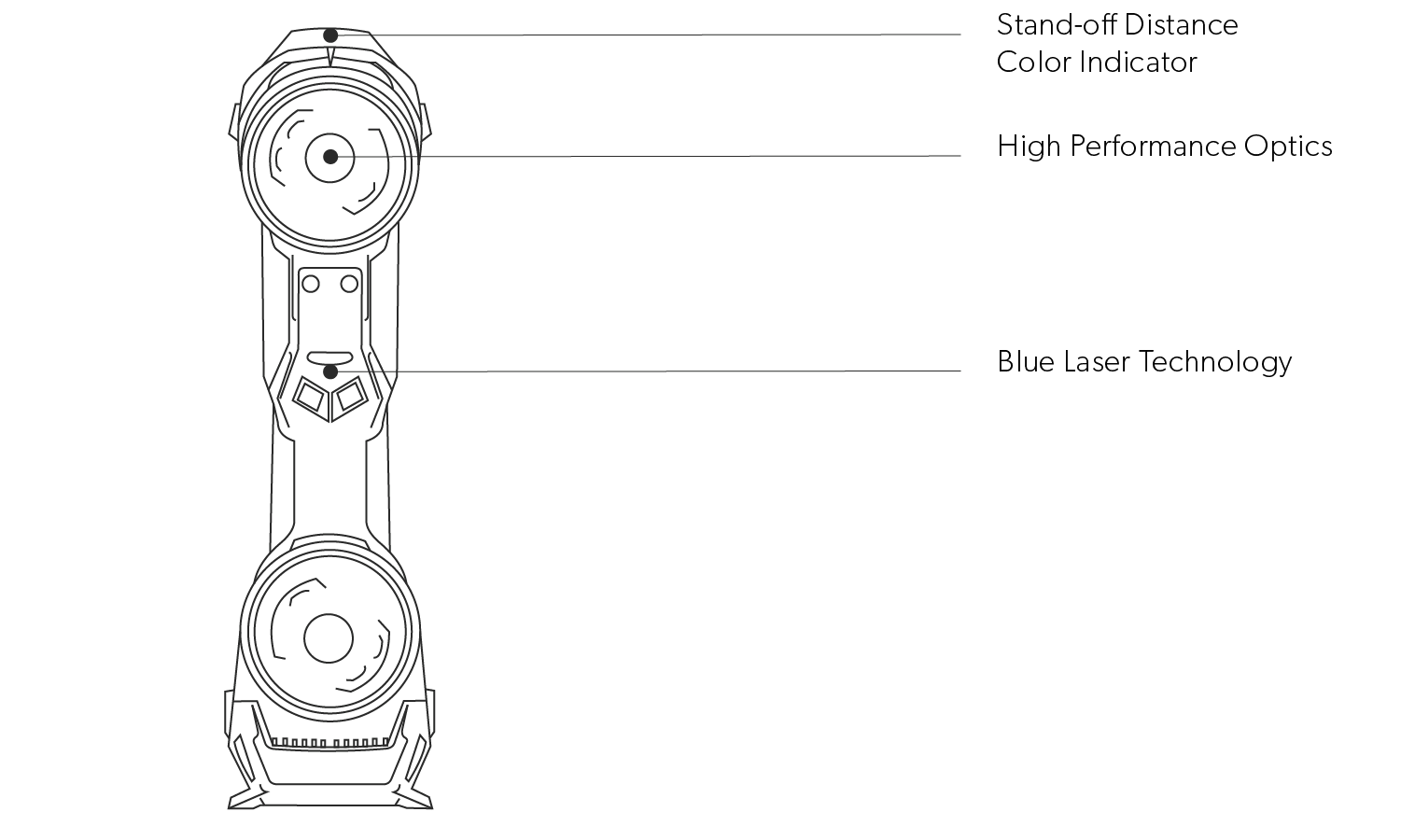

HandySCAN BLACK™ | Elite

Accuracy:

.0009 in

Volumetric Accuracy:

.0008 in + .0005in/ft

Measurement Resolution:

.0009 in

Measurement Rate:

1,300,000 measurements/s

Scanning Area:

12.2 x 13.8 in

Depth of Field:

9.8 in

Recommended Part Size Range:

.15 – 13 ft

Output Formats:

.dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf

Transforming the manufacturing landscape.

Are you looking to revolutionize your product development process? With 3D scanning technology, you can take your innovation to the next level by creating products tailored to your customer’s unique needs. Our 3D scanning service enables you to capture the precise measurements of any object and create a digital model that can be used to manufacture customized products. Instead of relying on the traditional one-size-fits-all approach, you can now offer your customers products that fit their specific requirements, increasing customer satisfaction and loyalty. Upgrade your manufacturing process with 3D scanning technology and stay ahead of the competition.

With our advanced 3D scanning solutions, you can:

- Capture intricate details with laser-sharp accuracy.

- Slash prototyping time and costs.

- Enjoy seamless production flow with less waste.

Why choose Prototek for your next project?

At Prototek, we provide an all-encompassing 3D scanning service that uses the latest scanning technology for utmost accuracy and precision. Our top-of-the-line facility and team of seasoned technicians ensure that every project is completed to the highest standards. We can handle various projects, from small parts to large objects, and offer multiple output formats, including fully optimized 3D models. At Prototek, we value customer satisfaction more than anything else and maintain clear communication, timely delivery, and affordable pricing. Whether you require a 3D scan for inspection, reverse engineering, or prototyping purposes, you can trust us to provide a dependable and efficient service.