In today’s manufacturing world, picking the correct production method is crucial for your project’s success. The benefits of cast urethane manufacturing is a versatile and efficient option for many applications. Here are eight essential benefits that make cast urethane an excellent choice for your next project.

1. Outstanding Cost-Effectiveness for Low to Medium-Volume Production

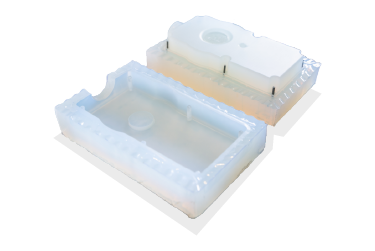

Cast urethane is a cost-effective choice for projects that don’t need large production runs. It uses silicone molds, which are much cheaper than the metal molds required for injection molding. Leading to lower upfront costs. Cast urethane is ideal for:

- Developing prototypes

- Producing small batches

- Creating custom projects

- Testing market ideas

2. Exceptional Material Versatility and Customization

Cast urethane is very versatile. You can change its properties to fit your project needs. Here are some of the options available:

- The hardness levels can be adjusted from soft to hard

- You can choose from different colors and finishes

- Custom textures and surface qualities are available

- You can select varying degrees of flexibility and stiffness

- It can resist specific chemicals

- This flexibility makes cast urethane suitable for many applications.

3. Superior Durability and Performance

Cast urethane products are well-known for their outstanding durability and performance. They provide:

- Excellent resistance to abrasion and wear

- High impact resistance

- Superior tear strength

- Good chemical resistance to oils and solvents

- Consistent performance over extended periods

- Enhanced load-bearing capabilities compared to similar materials

4. Rapid Prototyping and Quick Turnaround Times

Cast urethane production is much faster than traditional methods, especially when creating prototypes and small production runs. This speed comes from several factors:

- It takes less time to develop molds compared to metal tools.

- The setup and production processes are quicker.

- You can easily make design changes.

- Products can reach the market faster.

5. Complex Design Flexibility

Casting urethane is an excellent method for making parts with complex shapes that other methods might struggle with. It can produce:

- Detailed designs

- Parts with undercuts

- Complex geometric forms

- Fine surface details

- Several functions in one part

6. High-Quality Surface Finish and Aesthetics

This process provides high-quality surfaces that look great and offer:

- Professional finishes

- Consistent color

- Smooth or textured options

- High-polish features

- A production-quality appearance

7. Minimal Tooling Investment

Unlike traditional manufacturing methods, cast urethane needs much less investment in tools. This approach offers several benefits:

- Lower setup costs at the start

- Reduced financial risk for new products

- More affordable prototype development

- Flexibility to change designs without significant extra costs

- Cost-effective options for small production runs.

8. Environmental and Sustainability Benefits

Modern cast urethane manufacturing has several environmental benefits:

- It produces very little waste during the manufacturing process.

- It uses less energy than some traditional methods.

- The products last long, so you need to replace them less often.

- The materials can be recycled.

- It has a lower environmental impact when it breaks down.

The Benefits of Cast Urethane in Reflection

Cast urethane manufacturing is an excellent option for producing high-quality, durable parts at lower costs compared to traditional manufacturing. It works well for prototypes, small batches, or custom parts with specific properties. Cast urethane offers a good balance of quality, cost, and flexibility. In conclusion, the outstanding cost-effectiveness, exceptional material versatility, superior durability and performance, rapid prototyping, complex design flexibility, high-quality surface finish, minimal tooling investment, and environmental and sustainability benefits make cast urethane a compelling choice for your next project.

Many industries, such as medical devices, consumer goods, automotive parts, and industrial applications, have successfully utilized cast urethane manufacturing. For instance, cast urethane can create prototypes for new medical devices. In contrast, it produces custom parts with specific properties in the automotive industry. You can enjoy these benefits by choosing cast urethane for your project while achieving the desired results.

Keep in mind that cast urethane is best for low- to medium-volume production runs. If you need to produce very high volumes, methods like injection molding might save you money in the long run. Consider your project needs, production volume, and budget when deciding if cast urethane is the right choice.

FAQs

Cast urethane is a versatile material used for custom parts and prototypes.

Cast urethane offers excellent durability, flexibility, and resistance to abrasion, making it an ideal material for a wide range of applications.

Cast urethane parts can last several years, depending on the application and environmental conditions. They offer excellent durability and resistance to wear, making them a reliable choice for many industries.