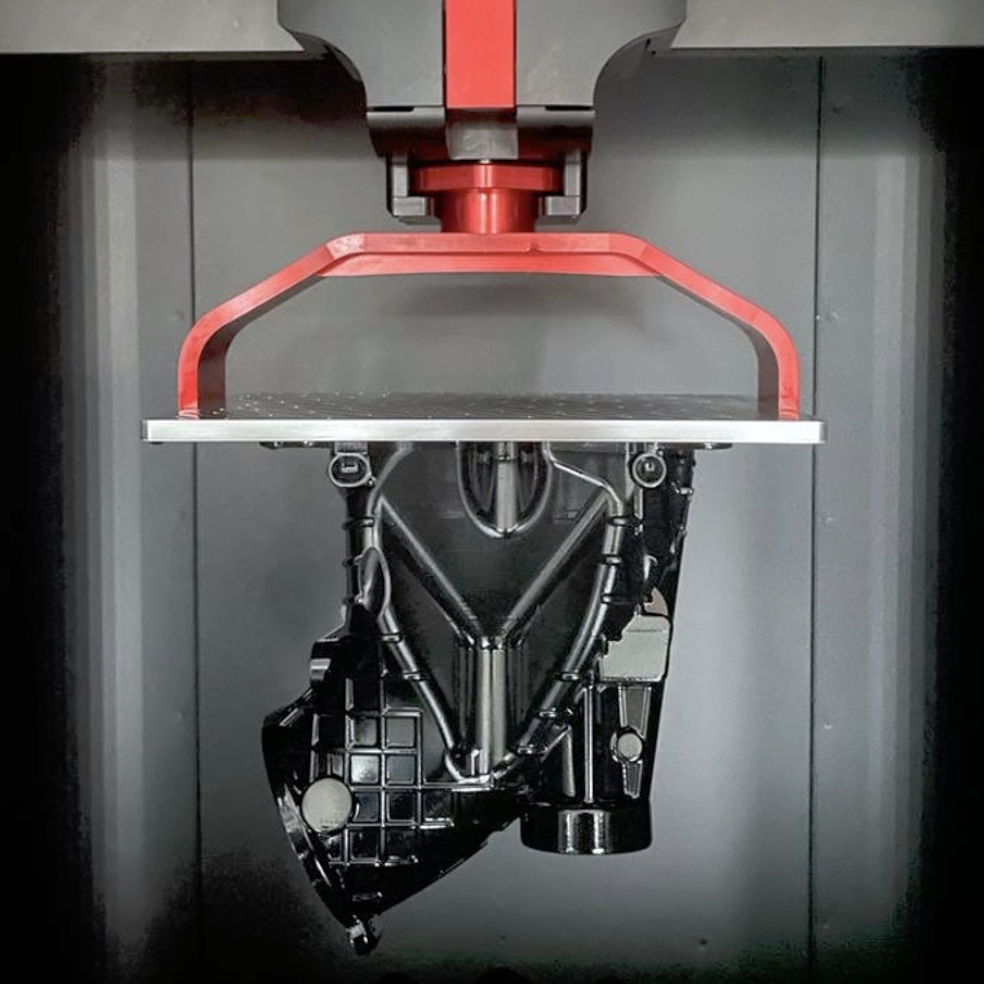

Midwest Prototyping has been at the forefront of promoting technologies and solutions that will benefit and impact our customers’ prototypes and end-use parts. We are excited to be the first additive manufacturer in the United States to adopt Axtra3D’s new technology that blends stereolithography and digital light processing to create highly accurate and efficient 3D prints.

This Hybrid PhotoSynthesis Technology is fast while maintaining incredibly smooth surface areas like injection molding. The Axtra3D Lumia offers a substantially larger build area than most 4k DLP machines with a 45-micron resolution. For more information about Axtra3D and their machines, visit their website in our opinion, this technology is very cool.

"We are constantly evaluating new technologies, trying to find those that will not only improve our business and our service to our customers but also move the industry forward. Over the past twenty years, this has included testing and development of hardware, software, materials, and post-processing techniques. Along the way, we have established a reputation as innovators and successful early adopters. We first connected with the Axtra 3D team over a year ago and immediately recognized the Lumia printer as a technology with the opportunity to be transformational. Fast forward to today, after much collaboration between our teams, I am thrilled to have the first machine in the world already making parts in our facility."

Steve Grundahl, VP of Additive Manufacturing, Prototek Tweet

Build Size (XYZ)

9.5 x 5.25 x 19.25 in

Layer Resolution *

25 to 200 microns

Resolution

45 microns

Materials

Open system compatible with 405 nm resins

* Material and design-dependent

Contact one of our Solutions Managers if you want to know what materials we’re running in our Lumia at solutions@midwestproto.com.