CNC Machine Shop Services

Prototek’s CNC Machine Shop services offer:

- Production-Grade Materials

- Price Breaks on Large-Volume Orders

- Precision & Repeatability

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- 100+ Materials

- 40+ Surface Finishes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

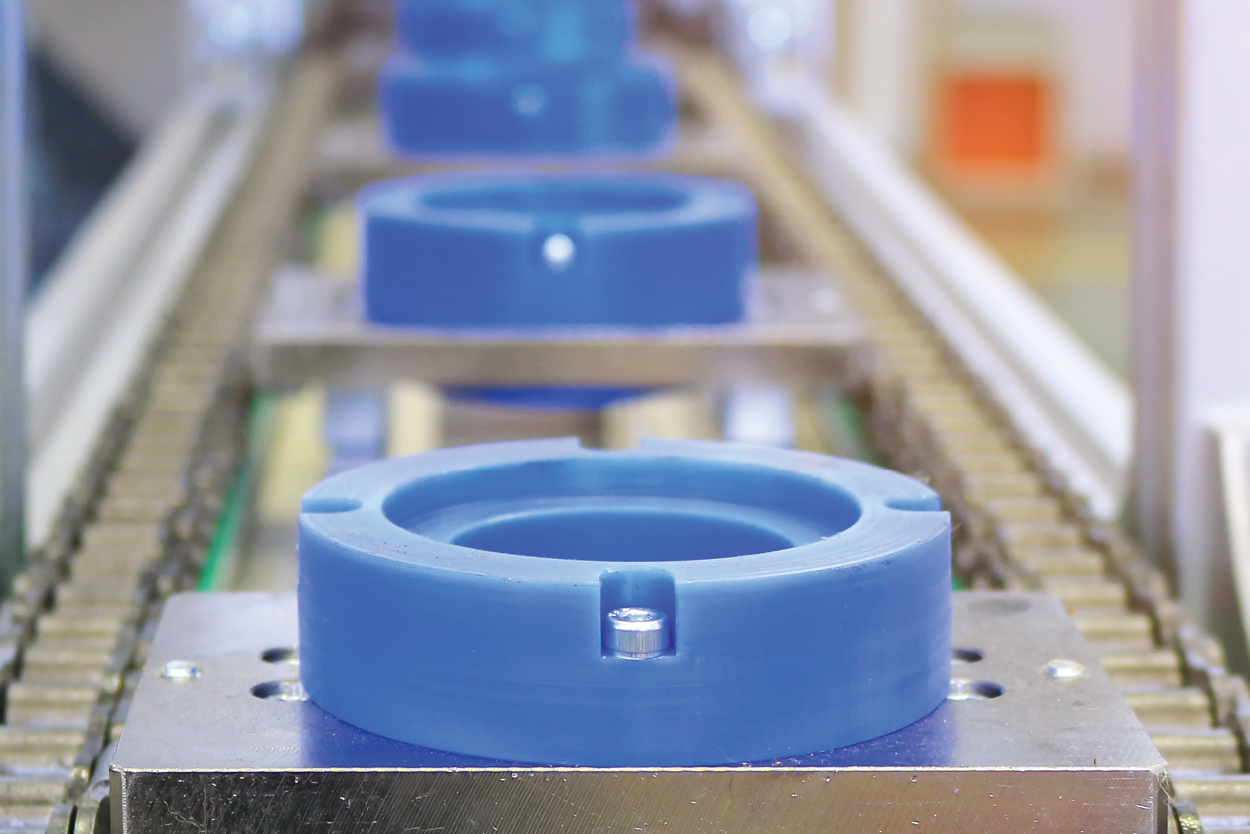

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

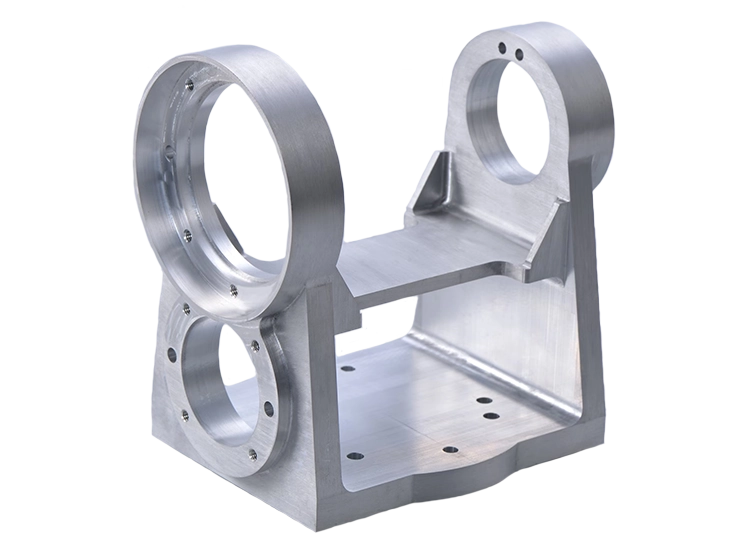

Our CNC Machine Shop Services

Our CNC manufacturing shops offer precise part prototyping and production for various industries. We provide a range of machining services, including milling, turning, routing, and wire and sinker EDM. Prototek’s highly skilled machinists can work with a variety of materials, including aluminum, steel, stainless steel, brass, plastics, ceramics, and composites. Furthermore, we offer assembly, welding, coating, and other advanced finishing and post-processing services to provide a complete solution. In addition, our quality control department ensures that each part meets your requirements and our high standards. We are dedicated to providing superior customer service and ensuring timely delivery. Please contact us to discuss your project and whether you need a prototype manufacturing shop or require large-scale production.

CNC Milling

Milling Machines

Akira Seiki, Atrump, Bridgeport, Brother, Daewooo, DMG Mori, Doosan, Haas, Hurco, Kent USA, Lagun, Matsuura, Mazak, OKK, Sharp, Sodick

Lead Time

5 – 22 Days

Max Dimensions

84 x 34 x 30 in

Prototek has many machines with different dimensions. This is the largest dimension available.

CNC Routing

Routing Machines

KOMO

Lead Time

5 – 22 Days

Max Dimensions

48 x 120 in

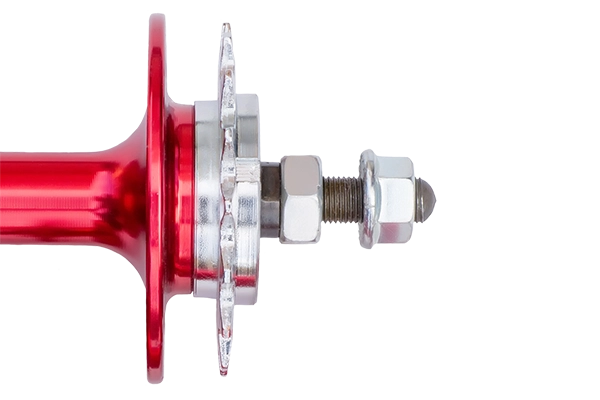

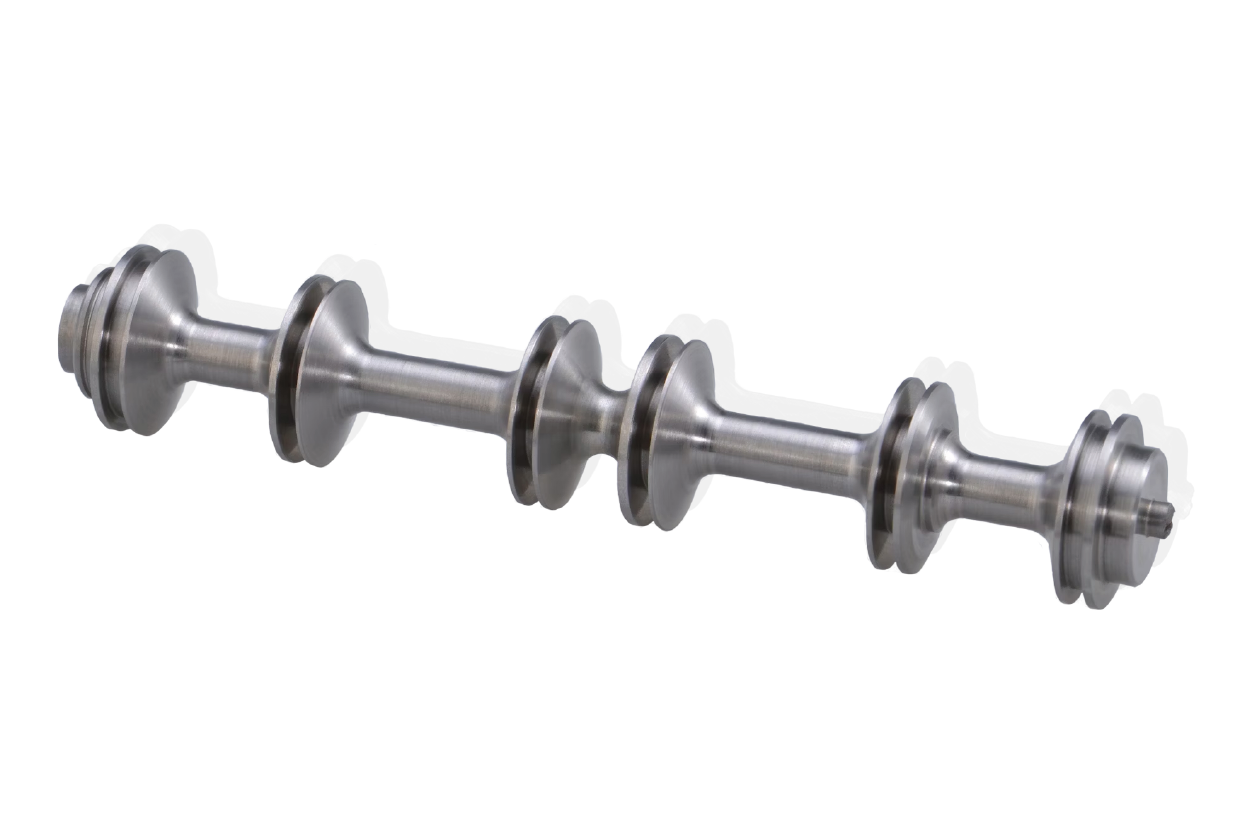

CNC Turning

Turning Machines

Acra-Turn, Atrump, Daewooo, Doosan, Enco, Haas, Hardinge, Hurco, Mazak, Trak Lathe

Lead Time

5 – 22 Days

Max Dimensions

XYZ | 84 x 34 x 30 in

Diameter | 12 in

Swing | 26 in

Wire & Sinker EDM

Wire & Sinker EDM Machines

Fanuc & Sodick

Lead Time

5 – 22 Days

Max Dimensions

31.5 x 23.6 x 31.5 in thick

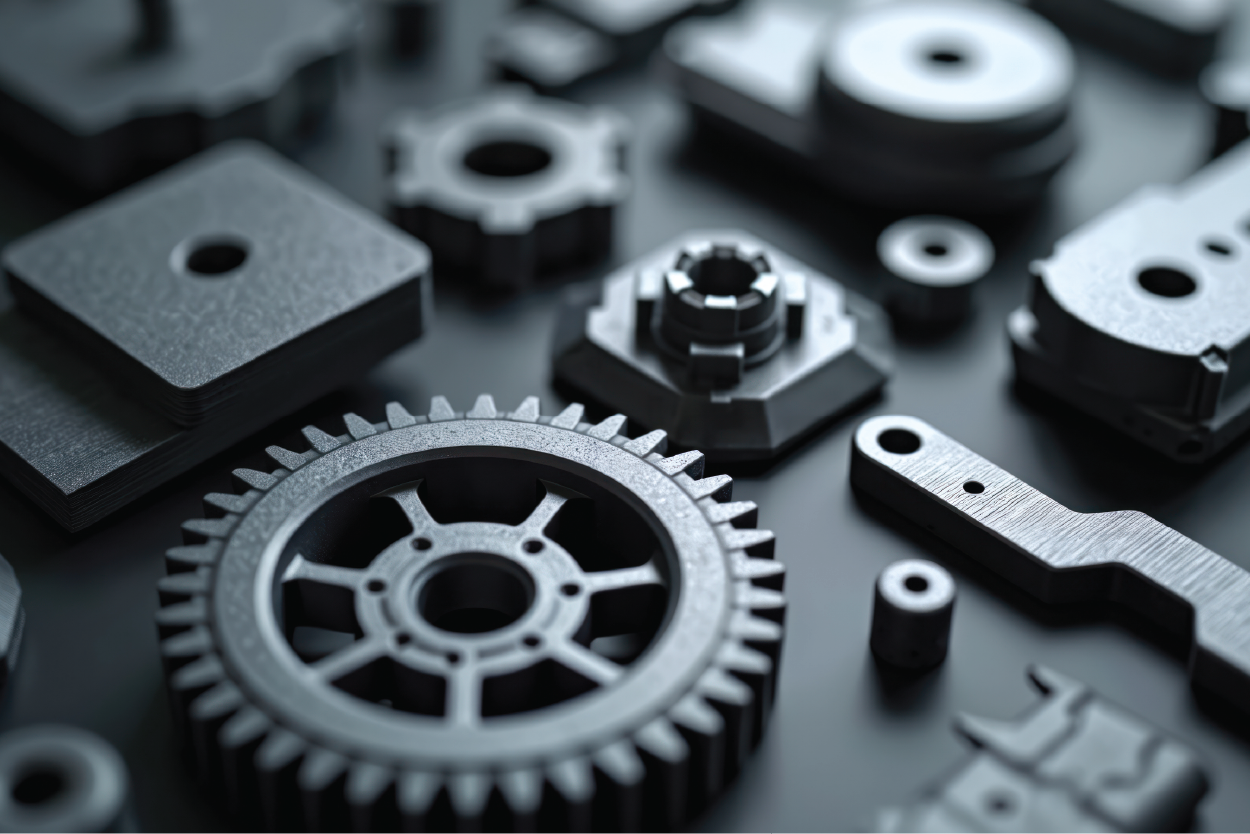

CNC Machine Shop Materials

At Prototek, we proudly offer a wide range of high performance composite, plastic, and metal materials for your project through our advanced CNC machine shop. Our team carefully selects and evaluates custom materials to ensure they meet your project’s unique requirements. Whether it requires corrosion resistant or electrically conductive materials we have you covered! Considering factors such as durability, precision, and finishing needs, we provide tailored solutions for projects of any size or complexity. In addition, our strong emphasis on quality and attention to detail ensures that every project is completed on time and surpasses the highest industry standards, giving you confidence in the reliability and performance of the final product.

Metals

- Aluminum

- Brass

- Bronze

- Copper

- Nickel Based High Temperature Alloys:

- Inconel

- Invar

- Kovar

- Nitronic 60

- Stainless Steel

- Steel

- Titanium

- Tool Steel

Plastics

- ABS

- Acrylic

- Acetal

- HDPE

- Nylon

- PEEK

- Polycarbonate

- Polypropylene

- Teflon/PTFE

- ULTEM

Other Materials

- G-10

- Machined Ceramics:

- Macor

- Wood

Does your project require a material not on our list?

Let us know if your project requires materials that are not on the list! We can accommodate other material requests, but quotes may need more time while we source the material.

CNC Machine Shop Finishes

The right finish is essential for CNC machine shop projects to ensure that the parts are functional, visually appealing, and defects-free. Our CNC service provides a range of finishes, such as sandblasting, powder coating, anodizing, graining, electroplating, painting, and polishing. Choosing the right finish for the material and intended use is essential. Feel free to contact us if you have any questions about the finishes available at our CNC machine shop.

High Quality Rapid Prototyping and Production Parts with CNC Machining

At Prototek Digital Manufacturing, we meet our clients’ needs by offering top-tier rapid prototyping and production part services through our advanced CNC machining capabilities. Our skilled team of engineers and technicians leverages cutting-edge technology to guarantee the utmost precision, efficiency, and dependability in every project we embark on. Whether your requirements entail intricately designed parts or essential components, we boast the knowledge and facilities to transform your concepts into reality swiftly and cost-effectively.

What is a CNC machine shop?

A CNC machine shop is a manufacturing facility that uses computer numerical control (CNC) machines to create precise composite, plastic, and metal parts and components. These advanced machines are programmed to automate the manufacturing process, enabling highly accurate and efficient production of a wide range of products. CNC machine shops provide various services, including CNC milling, turning, grinding, and more, which cater to the diverse needs of industries such as aerospace, automotive, medical, and others.

Expect Quality Machining From Prototek

At our company, we are steadfast in our commitment to delivering exceptional machining services. Our highly skilled team of engineers and technicians employs the latest cutting-edge technology to ensure that every project meets the highest standards of accuracy and dependability. We adhere to industry best practices, and our dedication to quality means that you can trust us to pay meticulous attention to detail and consistently exceed your expectations when you choose Prototek for your machining needs. Meticulous attention to detail and consistently exceed your expectations when you select Prototek for your machining needs.

Learn More About Prototek's CNC Machine Services

Through our resources, you can discover the complexities of CNC machining and gain insights into creating top-notch designs specifically tailored for this cutting-edge technology.

What Is Kovar and Why Is It Important?

Learn about Kovar, an important nickel-iron alloy used in electronics, aerospace, and medical devices. Since its development in the 1920s, Kovar has unique features like...

Designing Custom Jigs and Fixtures for Manufacturing.

These essential tools enhance precision and consistency and boost productivity on the shop floor. Discover how well-designed jigs and fixtures can streamline operations, reduce errors,...

Composite Materials: Innovations Shaping the Future

Composite materials are transforming industries with strength, lightweight nature, and design flexibility, particularly in aerospace and renewable energy. Advancements like nanocomposites and 3D printing enhance...

Precision CNC Machine Shop FAQs

CNC (Computer Numerical Control) machining is an exact manufacturing process that utilizes computer-controlled machines to create complex parts and components. By automating the machining process, CNC technology enables the production of intricate designs with exceptional accuracy and consistency, making it a versatile solution for a wide range of industries.

At Prototek, we offer various finishing options for your custom CNC machined parts, including anodizing, plating, painting, and more. Our experienced team can help you select the perfect finish to meet your specific requirements and enhance the appearance and functionality of your components.

Unparalleled accuracy, exceptional surface finish, and enhanced productivity.

CNC machining can have higher upfront costs and longer lead times than other manufacturing methods.

Absolutely! Prototek specializes in rapid prototype machine parts and short-run production, offering quick-turn CNC services to manufacture your parts efficiently and deliver them on time.

Why choose Prototek's CNC machine shop to manufacture your project?

Prototek is a top-rated CNC machine shop that provides reliable and high-quality services. Our team of engineers has vast experience in their field, ensuring that all their clients get excellent service. Moreover, Prototek is committed to quality, and customer satisfaction is unrivaled. We use modern, high-precision machinery to create parts that meet and exceed their clients’ specifications. Prototek is also flexible and willing to adapt to its clients’ unique requests, making it an ideal choice for anyone looking for bespoke fast CNC machining services.