Automotive Manufacturing

Parts in days anywhere in the USA.

Our automotive manufacturing capabilities:

- Instant Quotes and Engineer Assisted Quotes

- 100+ Metal and Plastic Materials

- 40+ Surface Finishes

- Quality Prototypes and End-Use Parts

Quality Matters | AS9100D Certified, ISO 9001:2015, & ITAR Registered

* Not all locations have the required certifications and registrations. We will manufacture parts that require these certifications at facilities that have them.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team will start production once we finalize the project details and you accept the quote.

When the part is complete, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

Don't let your project stall out - we're here to help!

The process of additive manufacturing, also commonly referred to as 3D printing, has numerous advantages when it comes to creating automotive components. It allows for intricate shapes and structures to be produced, reducing the need for assembly and increasing the durability and strength of parts. CNC machining is a highly versatile process that enables quick and precise creation of elements. It is popular for manufacturing various car parts, including engine components, steering systems, and suspension parts. Another notable method in auto manufacturing is sheet metal fabrication, which can shape aluminum and steel into lightweight parts, such as car doors and hoods. In summary, these manufacturing techniques offer many benefits, including improved functionality, faster turnaround times, lower production costs, and repeatability, making them a top choice in the automotive industry.

Additive Manufacturing for Automotive Manufacturing

The cutting-edge technologies of Additive Manufacturing, commonly called 3D printing, present an incredible opportunity to transform the automotive industry. It offers the ability to create designs faster, reduces tooling costs, and provides the capacity for customization. Moreover, it offers the potential for weight reduction, ultimately improving fuel efficiency. In automotive manufacturing, 3D printing has proven exceptionally beneficial for producing complex, low-volume parts such as engine components, chassis structures, and interior features. Additive Manufacturing enables automakers to make parts on demand, regardless of minimum order quantities, reducing waste and cutting costs. The revolutionary technology has taken the industry by storm, and its potential for further advancements and impact is immense.

A few automotive applications of additive manufacturing:

- Battery Housings

- Body Components

- Brackets

- Concept Models

- Cooling Systems & Ducts

- Dashboards/Consoles

- Engine Components

- Handles

- Knobs

- Lenses

- Mechanical Parts

- Trim Parts

- Wind Tunnel Testing

Case Study Spotlight: Switchgear Drives Performance

Ford and RTR Vehicles drive performance with functional testing for their collaborative project, the electric Switchgear, with Prototek’s SLA.

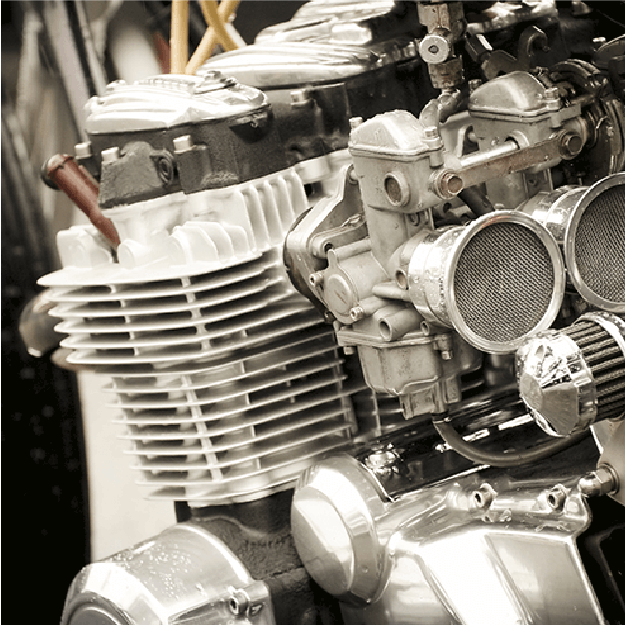

CNC Machining for Automotive Manufacturing

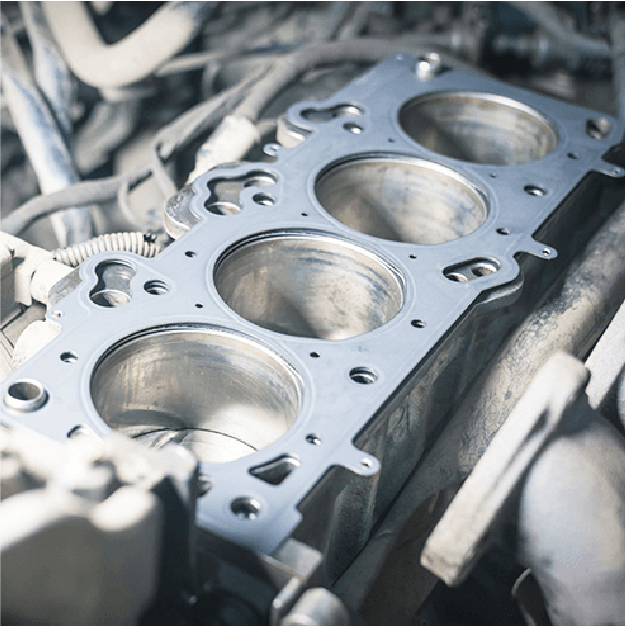

CNC machining has revolutionized the automotive manufacturing process, providing precise and accurate parts that are crucial in the industry. CNC machines utilize computerized numerical control (CNC) systems to control and manipulate the movement of tools and machinery, resulting in high precision and repeatability. They produce various parts such as engines, transmissions, suspensions, and body parts cost-effectively, efficiently, and reliably, reducing wastage, human error, and manufacturing times.

A few automotive applications of CNC machining:

- Brackets

- Cylinder Heads

- Dashboard Frames

- Drive Axles

- Engine Block

- Exhaust Systems

- Intake Manifold

- Interior Components

- Light Housings

- Gearbox

- Gears

- Starter

Sheet Metal Fabrication for Automotive Manufacturing

The automotive industry greatly emphasizes sheet metal fabrication as a primary manufacturing means. This technique is vital for producing lightweight and durable vehicle components while being cost-effective. Sheet metal fabrication is highly adaptable, enabling manufacturers to tailor each piece to individual design specifications, resulting in improved aesthetic appeal and vehicle value. This process allows for swift and efficient production, upholding the industry’s elevated manufacturing standards. In summary, sheet metal fabrication is a vital process that remains relevant within the automotive industry, continuing to make a significant impact.

A few automotive applications of sheet metal fabrication:

- Brackets

- Bushings

- Chassis

- Exhaust Systems

- Fenders

- Frames

- Hoods

- Panels

Additional Manufacturing Capabilities

3D scanning plays a crucial role in automotive manufacturing. It produces precise and intricate designs of car parts to enhance performance and safety. Additionally, it identifies defects and deviations in components to maintain high-quality standards and minimize recalls. It is also utilized in prototyping to create and test new designs before production, resulting in faster time to market and cost-saving benefits.

Silicone and urethane casting are two fast and cost-effective techniques for creating durable and precise parts in automotive manufacturing. Silicone casting employs a rubber mold and liquid silicone to produce small parts such as gaskets. In contrast, urethane casting uses a different rubber material and liquid polyurethane to mold more substantial parts like body panels. Both techniques offer exceptional precision and can be used to create complex designs.

Injection molding is a popular process in automotive manufacturing. It is a cost-effective and efficient way of producing high-quality, uniform parts such as bumpers and dashboards. The process involves melting plastic pellets and injecting them into a mold cavity to solidify into the desired shape. Injection molding machines can consistently produce thousands of parts per hour, reducing costs and manufacturing time while maintaining high-quality standards.

A few automotive applications of other manufacturing capabilities:

- Bushings

- Gaskets

- Interior Components

- Quality Control

- Reverse Engineering

- Seat Components

- Springs

- Suspension Insulation

Why choose Prototek to manufacture your automotive manufacturing project?

Prototek is the perfect choice for manufacturing automotive projects due to its immense experience and expertise in delivering cutting-edge solutions. With over 33 years of industry experience, we have served a wide range of clients across various industries, including automotive. We prides ourself on its lean manufacturing principles, quick turnaround times, and unparalleled quality control. We have invested heavily in state-of-the-art equipment and technologies that make them capable of delivering complex automotive parts and components with absolute precision and accuracy. Our team of experts consists of certified engineers, machinists, and technicians who understand the unique challenges faced in the automotive industry and are committed to delivering innovative solutions that exceed expectations. By choosing Prototek for your automotive manufacturing project, you can rest assured that you will receive exceptional product quality, attention to detail, and customer service.