Electric discharge machines (EDMs) are a versatile and powerful manufacturing technology that has revolutionized the production of complex parts and components. These advanced machines utilize controlled electrical discharges to remove material precisely. As a result, they allow for creating intricate geometries and features that would be difficult or impossible to achieve through traditional machining methods. At Prototek, we leverage the capabilities of EDM technology to deliver high-precision, custom-engineered solutions for our clients across a wide range of industries. In this blog post, we’ll explore the fundamentals of EDM and how it can benefit your manufacturing needs.

What is the history of Electric Discharge Machines?

Electrical Discharge Machining (EDM), also known as spark machining, is a versatile manufacturing process that has revolutionized the production of complex and intricate parts. Innovative technology originated in the late 18th century, marking a significant milestone in the history of modern manufacturing.

The foundations of EDM were laid in the 1770s. An English scientist, Joseph Priestley, discovered the erosive effects of electrical discharges on materials. This groundbreaking discovery paved the way for further advancements in the field. In the early 20th century, Russian scientists began exploring the potential of using electrical discharges for material removal. This led to the development of the first primitive EDM machines.

The 1940s saw a significant breakthrough in EDM technology as scientists in the United States and Japan developed more sophisticated EDM systems independently. These early machines utilized a submerged electrode and a workpiece, with the electrical discharges eroding the material to create the desired shape. As the technology continued to evolve, the 1950s and 1960s witnessed the introduction of servo-controlled EDM machines. These servo motors provided greater precision and control over the machining process.

Furthermore, the 1970s and 1980s marked a period of rapid advancements in EDM, with the development of computer numerical control (CNC) systems and the integration of advanced electronics. These innovations allowed for greater automation, improved surface finishes, and the ability to machine complex geometries with unprecedented accuracy.

Today, various industries widely use electric discharge machines, including aerospace, automotive, medical, and tool and die manufacturing. The technology has continued to evolve with the introduction of wire EDM, which uses a thin wire electrode to cut intricate shapes, and die-sinking EDM, which creates complex cavities and molds.

In conclusion, Electrical Discharge Machining remains a crucial tool in modern manufacturing. As the landscape evolves, enabling the production of parts and components that were once considered impossible.

What types of electric discharge machines are there?

Electric discharge machines (EDMs) are versatile and powerful manufacturing tools used to precisely shape and cut a wide range of materials. There are several main types of EDMs, each with their unique capabilities and applications:

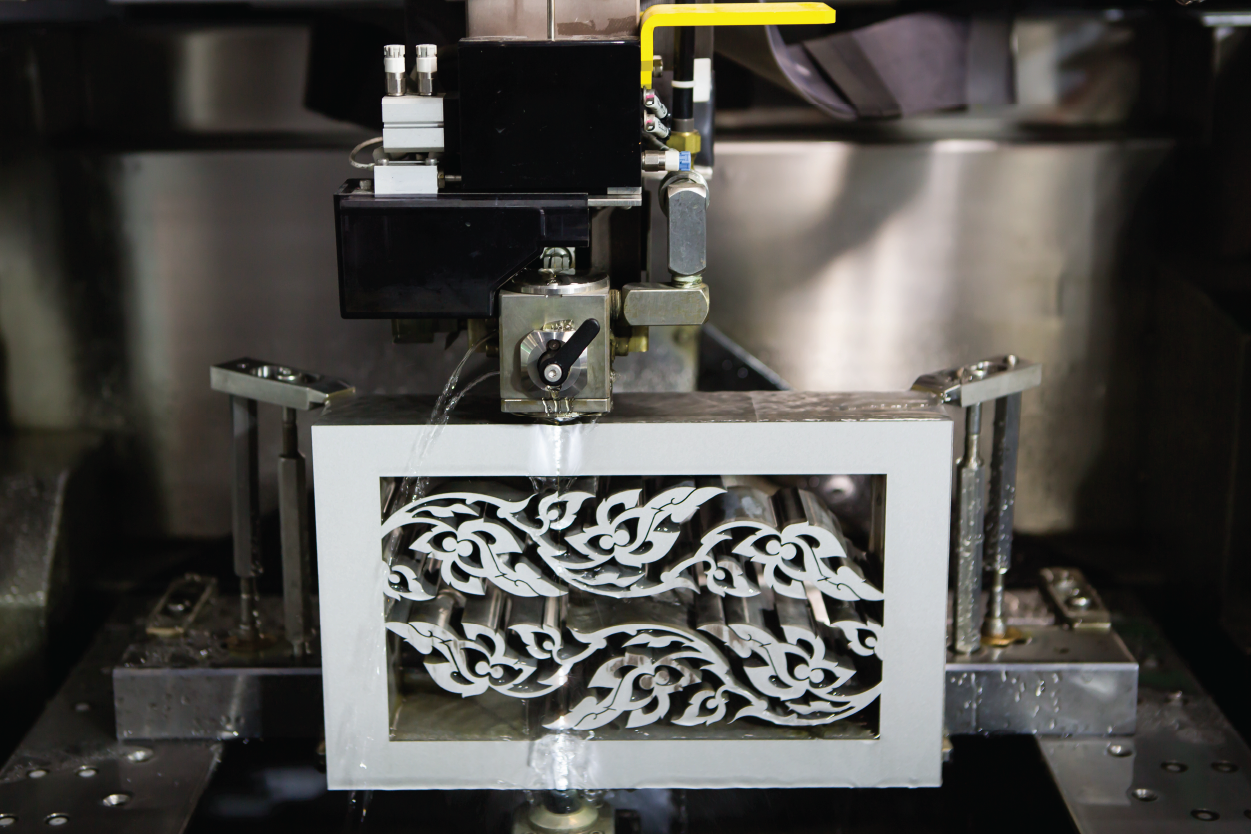

Wire EDM

Wire EDM, or Wire Electrical Discharge Machining, is a precise manufacturing process that utilizes a thin, charged wire to cut and shape conductive materials. This advanced technology also enables the creation of complex, intricate parts with exceptional accuracy and surface finish. By employing a series of precisely controlled electrical discharges between the wire and the workpiece, Wire EDM can produce parts with tight tolerances and complex geometries that would be challenging or impossible to achieve through traditional machining methods.

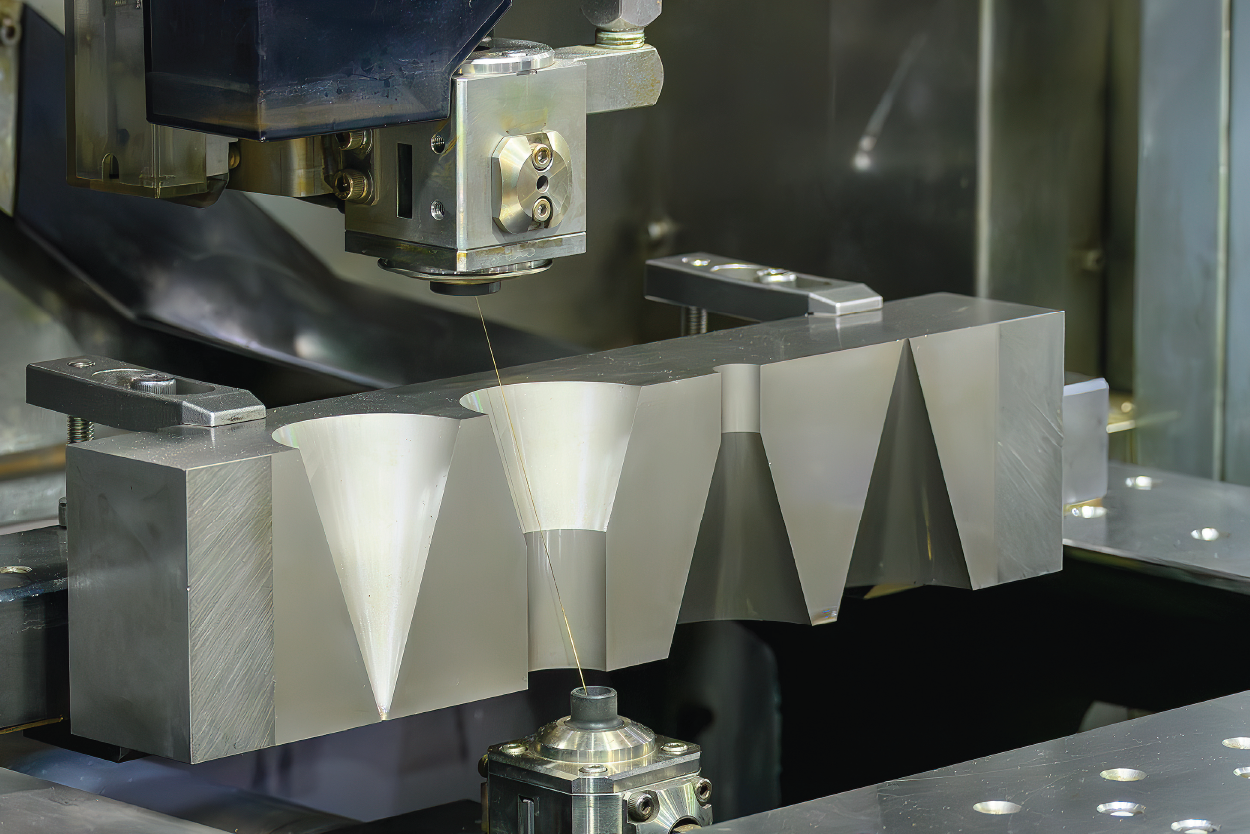

Sinker EDM

Sinker EDM, or Electrical Discharge Machining (EDM), is a non-traditional machine that utilizes electrical discharges to remove material from a workpiece. This process is particularly beneficial for creating complex shapes and intricate features in hard-to-machine materials. By precisely controlling the electrical discharges, Sinker EDM enables the creation of detailed and accurate parts, making it a valuable tool in various manufacturing applications.

Hole EDM

Hole Drilling Electrical Discharge Machining (EDM), or Hole EDM, is a non-traditional machine that utilizes electrical discharges to remove material from a workpiece. This process is particularly effective for creating precise, complex, and intricate holes and cavities in hard-to-machine materials. Additionally, by precisely controlling the electrical discharges, Hole EDM can produce high-quality, burr-free holes with tight tolerances, making it a valuable technique for various manufacturing applications.

Micro EDM

Micro EDM, or Micro Electrical Discharge Machining, is a precise manufacturing process that utilizes electrical discharges to remove material from conductive workpieces. This advanced technology enables the creation of intricate and complex parts with exceptional accuracy and surface finish, making it a valuable tool in aerospace, medical devices, and electronics industries. Additionally, Prototek Digital Manufacturing provides state-of-the-art micro EDM capabilities to meet the demanding requirements of our clients.

Each type of EDM machine has unique advantages that make it well-suited for different manufacturing applications. Furthermore, understanding the capabilities of these versatile processes is critical to leveraging their full potential.

What are a few EDM applications?

Electrical Discharge Machining (EDM) is a highly versatile and precise manufacturing process that utilizes electrical discharges to shape, drill, or cut conductive materials. It is widely employed in aerospace, automotive, and medical manufacturing industries to create complex and intricate parts that may be difficult to produce using traditional machining methods. Moreover, EDM benefits materials are challenging to machine with conventional tools, such as hardened steel or exotic alloys. This process offers high accuracy and the ability to create intricate and delicate shapes without inducing stresses or distortion in the workpiece. Notably, some applications in various industries include:

Aerospace

EDM is widely used to produce complex aerospace components such as turbine blades, fuel nozzles, and other intricate parts requiring precise and detailed machining.

Automotive

EDM manufactures automotive components, including engine parts, transmission components, and die-cast molds for various automotive applications.

Medical

EDM is instrumental in fabricating medical implants, surgical instruments, and other precision medical devices that require intricate geometries and tight tolerances.

Electronics

EDM produces electronic components, printed circuit boards, and other miniaturized parts that require precise and delicate machining.

Tool and Die

EDM is a crucial process in creating intricate tool and die designs, enabling the production of complex molds, punches, and other specialized tooling.

Overall, EDM’s ability to precisely machine conductive materials, regardless of their hardness, makes it a versatile and valuable manufacturing technique across diverse industries.

Why choose electric discharge machines for your project?

Electrical discharge machining (EDM) is a versatile and precise manufacturing process that can significantly impact your project. Additionally, its capability to create intricate and complex geometries makes EDM an ideal choice for producing parts with tight tolerances and delicate features. By utilizing controlled electrical discharges, EDM can machine conductive materials with unparalleled accuracy, making it a top choice for industries spanning from aerospace to medical devices. Unleash the full potential of your project with the precision and flexibility of electrical discharge machining from Prototek Digital Manufacturing.

FAQs

It is a non-traditional manufacturing process that uses electrical sparks to remove material.

Electric discharge machining can fabricate various conductive materials, including metals, alloys, and some ceramics.

Electrical, aerospace, automotive, medical, and tool & die industries commonly utilize electric discharge machining.