Polypropylene is a highly versatile and widely used thermoplastic polymer with a rich history, remarkable mechanical properties, and diverse applications. In this blog post, we will explore the origins of polypropylene, delve into its unique physical and mechanical characteristics, and uncover how it has transformed industries across the globe. We will also examine why it has become indispensable to our modern world.

What is the history of polypropylene, and how is it made?

Polypropylene, a widely used and versatile thermoplastic polymer, was first synthesized in 1954 by Italian chemist Giulio Natta. Natta’s breakthrough was developing a catalyst system that could produce isotactic polypropylene, giving the plastic its unique properties. Consequently, polypropylene has become essential across many industries due to its strength, stiffness, heat resistance, and low cost.

The manufacturing process involves distilling crude oil to produce propylene gas and using a catalyst to form long polymer chains, effectively polymerizing it. Subsequently, the molten polypropylene creates pellets or chips by extrusion and cooling for further processing.

Polypropylene’s versatility allows its use for various applications, from rigid plastics to flexible films. Its history of innovation ensures that new applications for this remarkable polymer will continue to come to fruition.

What are the mechanical properties of polypropylene?

Polypropylene is an incredibly versatile thermoplastic polymer recognized for its outstanding mechanical properties. Some of the critical mechanical properties of polypropylene are as follows:

High Tensile Strength

Polypropylene is an exceptionally robust and durable thermoplastic polymer, widely used in various applications due to its excellent physical and chemical properties. It exhibits a typical tensile strength range of 2,900 to 5,800 psi (20 to 40 MPa), making it suitable for various industrial and consumer product uses.

Impact Resistance

Polypropylene is a highly suitable material for applications that demand exceptional impact resistance, particularly in environments with lower temperatures. Its ability to withstand impact makes it an ideal choice for various products and industries, including automotive components, packaging materials, and consumer goods.

Unique Combination of Flexibility and Stiffness

Polypropylene possesses a relatively low modulus of elasticity, which means it can flex and resist deformation while retaining a high level of stiffness. It is an ideal material for applications requiring flexibility and stiffness, such as manufacturing various products, including packaging and automotive components.

Fatigue Resistance

Polypropylene’s fatigue resistance is a crucial attribute that maintains its structural integrity and performance when subjected to repeated stress and strain over time. Meaning it can withstand various mechanical forces without experiencing failure, making it a reliable and durable material for multiple applications.

Low Density

Polypropylene is an exceptionally lightweight thermoplastic polymer with a low density of approximately 0.9 g/cm³. This characteristic makes it well-suited for various applications where minimizing weight is crucial. Industries such as automotive, packaging, and aerospace utilize this material due to its lightweight nature, which helps reduce fuel consumption, transportation costs, and overall energy usage.

What industries use this material?

Polypropylene is a versatile thermoplastic polymer that finds widespread use across various industries due to its unique properties. Some of the key sectors that utilize it include:

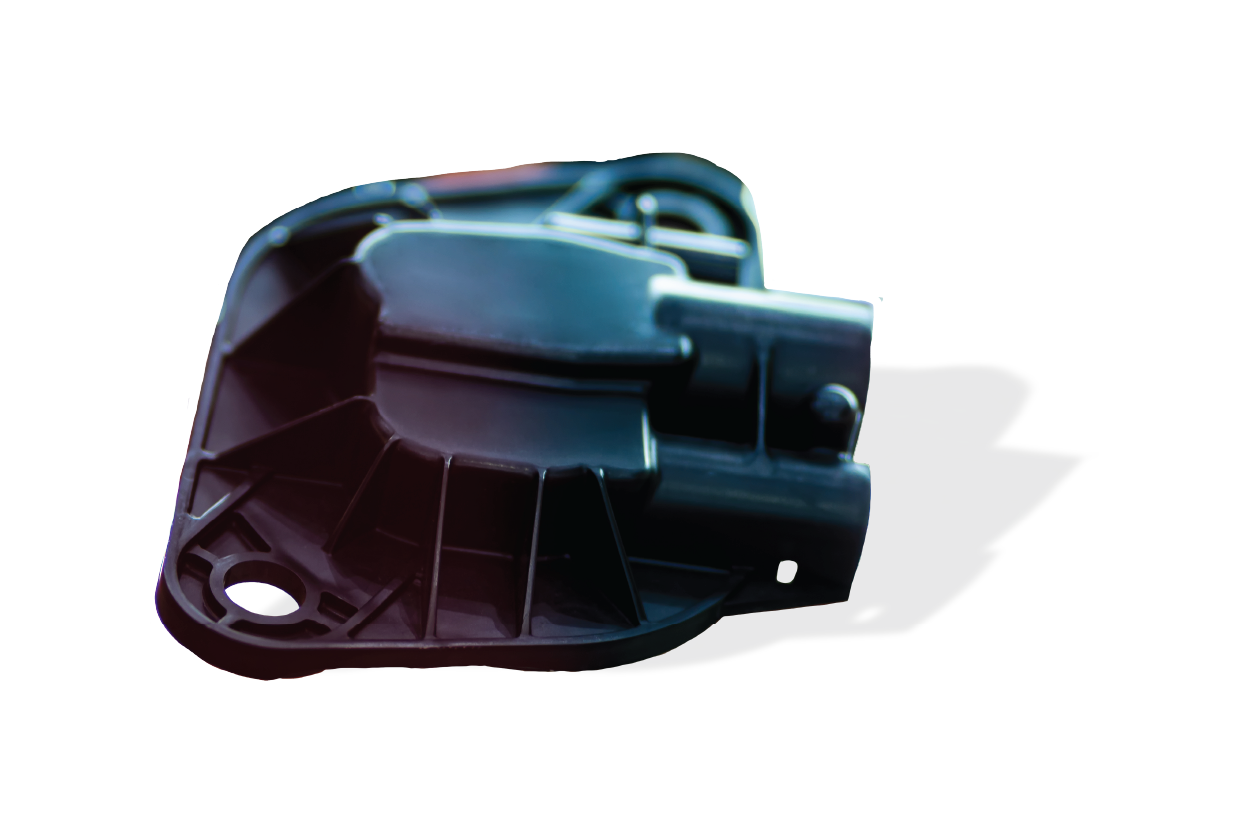

Polypropylene in the Automotive Industry

Polypropylene, a thermoplastic polymer, is extensively utilized in the automotive industry due to its exceptional properties. It’s use in the production of various interior and exterior components, including, but not limited to, bumpers, dashboards, door panels, and a wide range of other parts. This versatile material is favored for its durability, impact resistance, lightweight nature, and ability to withstand harsh environmental conditions, making it an ideal choice for automotive applications.

Packaging Industry

Polypropylene is a versatile thermoplastic polymer that has become increasingly popular in the packaging industry. Its excellent chemical resistance, impact strength, and heat resistance make it ideal for various packaging applications, including food containers, bottles, caps, and closures. Its lightweight and cost-effective properties also make it a preferred choice for many manufacturers looking to optimize their packaging solutions.

Polypropylenes use in Appliances and Electronics

Polypropylene is a versatile thermoplastic polymer that has become increasingly popular in the appliance and electronics industries. Its unique properties, such as high impact resistance, chemical resistance, and low density, make it an ideal material for various applications. In appliances, polypropylene is commonly used for components like housings, handles, and internal parts, providing durability and a sleek, modern appearance. In the electronics sector, polypropylene is utilized for enclosures, connectors, and insulation, ensuring reliable performance and protection for sensitive electronic components. The adaptability and cost-effectiveness of polypropylene make it a preferred choice for manufacturers seeking to enhance the functionality and aesthetics of their products.

Construction Industry

Polypropylene is a versatile thermoplastic material with numerous applications in the construction industry. Its durability, chemical resistance, and lightweight properties make it an ideal choice for various construction products. For example, pipes and fittings for plumbing and drainage systems, roofing materials such as waterproof membranes and shingles, insulation materials including foam boards and spray-applied insulation, flooring products like vinyl tiles and carpets, packaging and containers for construction materials, automotive components used in construction vehicles, and furniture and fixtures for construction site offices and temporary structures.

Why choose polypropylene for your project?

Polypropylene is a versatile and durable thermoplastic material that offers numerous advantages for your project. Its exceptional strength-to-weight ratio, chemical resistance, and thermal stability make it an ideal choice for various applications. With its cost-effectiveness and ease of processing, polypropylene can help you achieve your design goals while optimizing your project’s efficiency and performance.

FAQs

It is a highly versatile thermoplastic polymer with various applications across various industries and sectors. Its unique properties make it ideal for many uses, from packaging materials to automotive components, showcasing its adaptability and functionality.

It is a versatile and widely used polymer crucial in various industries, including automotive, packaging, healthcare, and consumer goods. Its unique properties, such as durability, resistance to chemicals, and lightweight nature, make it an ideal choice for manufacturing a wide range of products that cater to the needs of consumers and businesses alike.

Various applications, including packaging, automotive parts, and household items. This versatile thermoplastic polymer is favored for its durability and resistance to multiple chemicals, making it ideal for consumer goods and industrial uses.

This material can be finished with various options, including matte, glossy, and textured surfaces.