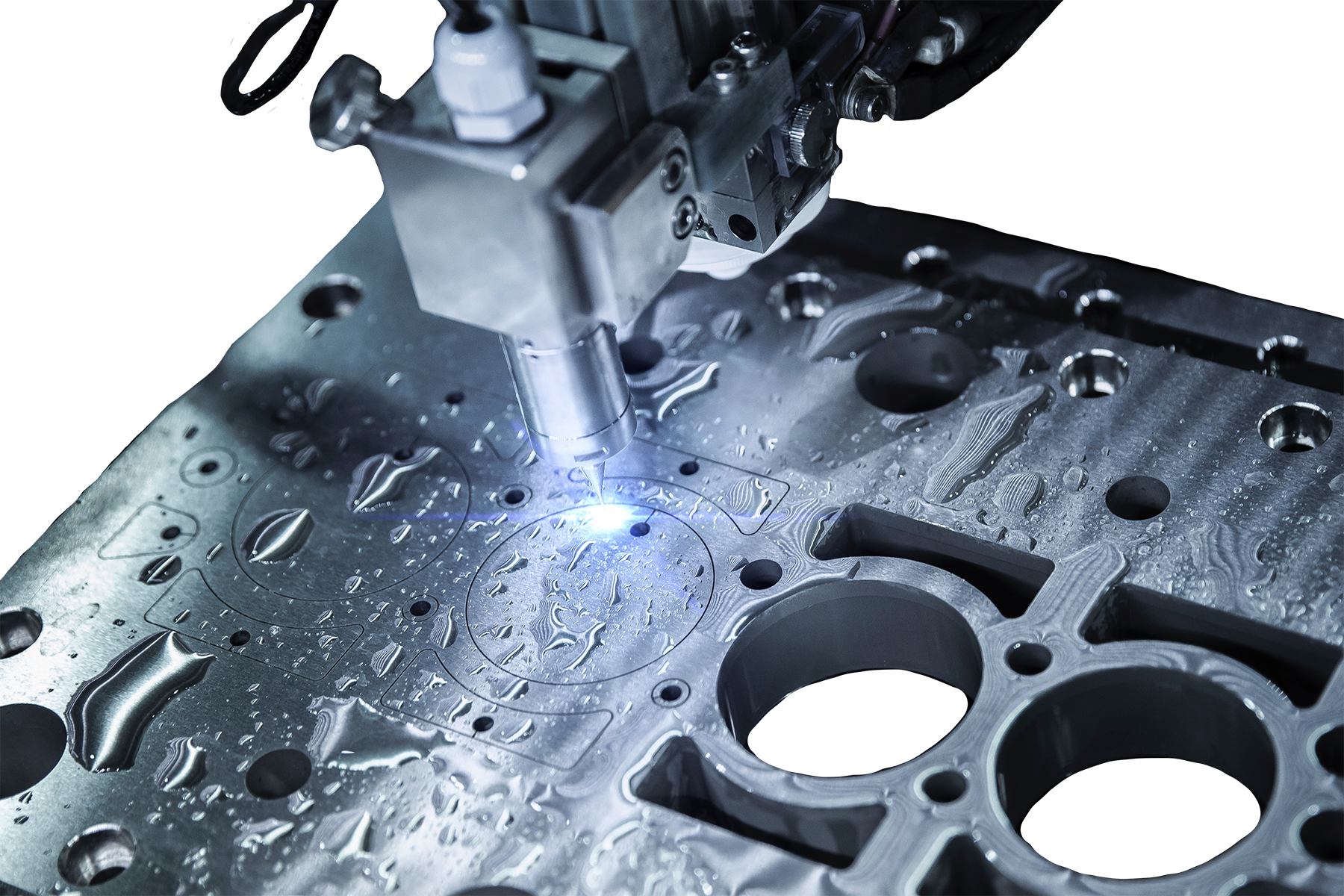

Laser welding, a precise and efficient joining process, has significantly impacted the manufacturing industry. This technology, which has its roots in the mid-20th century, has evolved to become a key player in modern manufacturing. By harnessing the power of concentrated light energy, this advanced technique enables the seamless fusion of various materials, including metals and plastics. This blog post will delve into the fundamentals of laser welding and its key benefits.

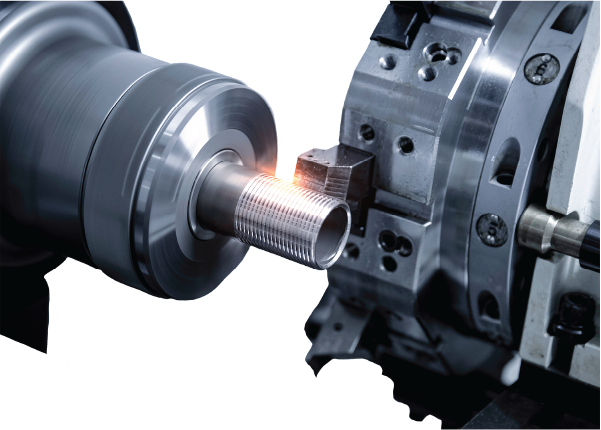

How does laser welding work?

Laser welding is an exact and efficient method for joining materials that uses the concentrated heat of a focused laser beam. This beam is directed at the area to be joined, quickly heating and melting the materials. Which then solidifies and creates a potent and seamless weld. This technique can weld various materials with exceptional accuracy and minimal distortion. Due to its versatility, speed, and ability to produce high-quality, consistent welds, different industries use this welding method, including automotive, aerospace, electronics, and medical device manufacturing.

This step-by-step guide outlines the stages of the laser welding process.

1. Prepare the Workpiece: Clean the surfaces to be welded, ensuring they are free of contaminants that could compromise the quality of the weld

2. Set Up the Laser Welding Machine: Adjust the laser power, beam focus, and travel speed according to your project’s specific requirements.

3. Position the Workpiece: Secure the components, ensuring proper fit and alignment for a seamless weld.

4. Initiate the Welding Process: Activate the laser and guide it along the joint, carefully monitoring the formation of the weld pool and its penetration.

5. Inspect the Weld: Visually examine the weld for any defects or irregularities. Conduct any necessary non-destructive testing to verify the integrity of the joint.

6. Finish and Post-Process: Perform any required finishing steps, such as cleaning or surface treatment, to enhance the appearance and performance of the welded assembly.

What materials can be laser welded?

Laser welding is a highly adaptable joining technique that is effective for various materials, showcasing its broad applicability and potential to revolutionize various industries.

Aluminum

Aluminum is known for its excellent thermal conductivity, making it an ideal material for welding. When utilizing laser technology for welding aluminum, the concentrated energy promotes rapid melting and solidification, producing solid and high-quality welds. Additionally, laser welding minimizes heat-affected zones, reducing the risk of warping or distortion in the aluminum structure.

Copper

Although challenging, a laser welder can join copper parts by carefully controlling the process parameters. Key factors such as laser power, beam focus, travel speed, and pulse duration are crucial in achieving optimal weld quality. By precisely adjusting these parameters, operators can enhance the heat input, ensure proper melting of the copper parts, and minimize defects like porosity or warping. This level of control is essential for creating strong, reliable joints in applications where copper’s thermal and electrical conductivity is critical.

Nickel Alloys

This method offers a precise and localized heat source, making it particularly well-suited for welding nickel-based superalloys. Concentrating heat on a specific area minimizes thermal distortion and preserves the superalloys’ material properties. This controlled approach allows for better fusion of the metals, leading to solid and durable welds that can withstand extreme temperatures and harsh environments, which are typical for nickel-based superalloy applications.

Stainless Steel

Laser welding is a highly effective technique for joining stainless steel components. One of the key advantages of welding laser is its ability to minimize thermal distortion due to the concentrated heat input, allowing for precise control over the weld pool. The result is a seamless appearance with excellent structural integrity, making it ideal for applications where aesthetics and strength are critical. Additionally, laser welding can be easily automated, increasing efficiency and repeatability in manufacturing processes.

Titanium

The laser welding approach for joining two or more pieces is particularly beneficial as it helps maintain titanium’s intrinsic properties, which include strength, corrosion resistance, and a lightweight nature. The precisely focused beam allows for a cleaner weld with fewer impurities and a lower likelihood of oxidation, which is crucial when working with titanium and its alloys. Laser welding is advantageous for achieving solid and high-quality welds while preserving the unique attributes that make titanium a preferred material in various industries.

Ceramics

Advanced laser beam welding techniques have revolutionized the joining of ceramic materials, creating solid and durable bonds. These methods are particularly beneficial for applications that demand exceptional resistance to high temperatures, making them ideal for the aerospace, automotive, and electronics sectors. These techniques can precisely melt and fuse ceramic components using focused laser beams without compromising their structural integrity. This capability enhances the performance and longevity of ceramic products and opens up new possibilities for innovative designs and applications in environments where traditional joining methods may fail.

Composites

This welding technique is becoming increasingly popular in the automotive and aerospace industries, where the need for lightweight yet high-strength components is critical. Utilizing composite materials made of fibers and resins allows for the creation of structures that reduce overall weight and enhance durability and performance. Integrating these advanced materials helps manufacturers meet stringent safety and efficiency standards while improving fuel efficiency and reducing emissions in vehicles and aircraft. As industries continue to push the boundaries of engineering, this technique plays a pivotal role in developing innovative designs and applications.

Plastics

Laser welding is a highly specialized process that can effectively join thermoplastics, offering the advantage of creating robust hermetic seals. This technique eliminates the need for adhesives or mechanical fasteners, which can compromise the integrity of the joint. Using focused laser energy, materials are joined at the molecular level, resulting in a seamless connection that is often stronger than the surrounding material. This method not only enhances the durability of the welded joint but also ensures that it is resistant to environmental factors such as moisture and contaminants, making it an ideal choice for applications requiring high reliability and precision.

What are the benefits of laser welding?

Laser welding offers a range of benefits that make it a highly versatile and efficient joining process. Some of the key advantages of laser welding include:

Precision and Accuracy

With its remarkable precision, laser beam welding allows for the creation of joints with extremely tight tolerances and intricate weld patterns. This technique utilizes concentrated laser beams, resulting in minimal heat-affected zones.

High Speed

The remarkable speed of the laser weld process is one of its most significant attributes contributing to its overall efficiency. This rapid operation allows for a substantial increase in productivity and throughput, which can profoundly impact various manufacturing projects.

Minimal Heat Input

The laser welding device joins workpieces by generating a highly localized heat input. This precision allows for a narrower heat-affected zone (HAZ) than traditional welding methods. As a result, there is less thermal spreading, which minimizes the extent of alterations in the material properties surrounding the weld.

Clean Process

Laser welding is a clean and fume-free process, reducing the need for post-weld cleaning and significantly improving the work environment. This emphasis on a cleaner work environment can make the audience feel the positive impact on their daily operations.

Versatility

Laser welding is suitable for an extensive range of materials, encompassing various types of metals such as steel, aluminum, and titanium, as well as non-metallic substances like plastics, ceramics, and composites. The ability to manipulate the laser’s power, speed, and focus allows for fine-tuning of the welding process to meet the specific requirements of different materials and thicknesses.

Why choose laser welding for your project?

Laser welding offers unparalleled precision, speed, and efficiency for manufacturing projects. It is ideal for many applications because it creates high-quality, consistent welds. Learn about the benefits of this advanced technology and see how it can elevate your project to new heights.

CNC Machine Shop Services

Prototek offers state-of-the-art CNC machining services to meet your precise manufacturing needs. Our skilled technicians utilize the latest CNC technology to deliver high-quality components with unparalleled precision and efficiency—Trust Prototek for all your CNC machining requirements.

Sheet Metal Fabrication Services

At Prototek, we offer comprehensive sheet metal fabrication services to meet your manufacturing needs. Our skilled team utilizes the latest technology and techniques to deliver high-quality, precision-engineered components. From prototyping to production, trust Prototek to bring your ideas to life.

FAQs

It is a precise and efficient joining process that uses a concentrated beam of light to fuse materials.

It can join a variety of metals, including steel, aluminum, titanium, and stainless steel, and nonmetals such as ceramics, composites, and plastics.

Aerospace, automotive, and electronics industries commonly use this precise welding process.