Choosing the right conversion coating for your project is crucial as an engineer, project manager, or professional in an industry that involves metal surfaces. It requires a solid understanding of the various options available and their suitability for your specific needs. Your selection will significantly affect the material’s performance, durability, and appearance.

This blog post aims to provide essential information about conversion coatings, the types available, their benefits, and guidance on how to make the best selection for your project.

What Are Conversion Coatings?

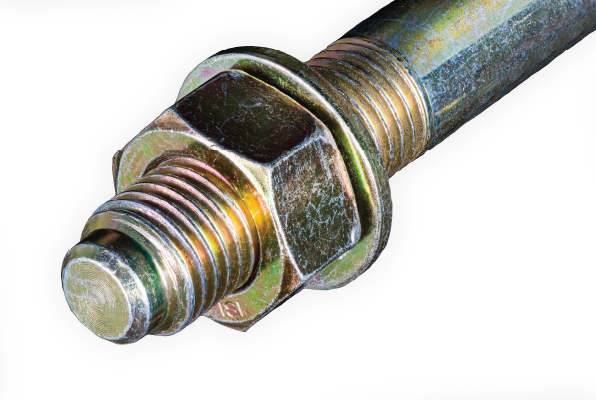

Conversion coatings are treatments applied to metal surfaces to improve their properties. Unlike traditional coatings like paint or powder that sit on top, conversion coatings react with the metal to create a thin protective layer. This layer helps prevent rust, improves how well paint sticks, and can enhance the appearance of the metal.

Common uses for conversion coatings include:

- Automotive and aerospace parts to prevent rust and increase strength

- Architectural features to improve metal finishes

- Electronics to protect against environmental damage

Types of Conversion Coatings

Conversion coatings offer various options, each designed for specific metals and purposes. This variety ensures that you can find the perfect solution for your project. Here are some of the most common types and their features:

Phosphate Coatings

Steel and other ferrous metals use phosphate coatings, which react with the metal to create a layer of phosphate salts.

Common Types of Phosphate Coatings:

- Zinc phosphate

- Iron phosphate

- Manganese phosphate

Key Benefits of Phosphate Coatings:

- They help paint stick well.

- They offer some protection against rust.

- They reduce friction in parts like automotive engines.

Applications of Phosphate Coatings:

- Automotive parts

- Appliances

- Industrial equipment

Chromate Coatings

Chromate conversion coatings protect aluminum and zinc alloys from corrosion and provide strong adhesion, making them ideal for painting or priming.

Key Benefits of Chromate Coatings:

- They resist corrosion very well.

- They help paint, and primers stick better.

- They come in clear or colored finishes like yellow, green, or iridescent.

Environmental Considerations for Chromate Coatings:

Traditional chromate coatings use hexavalent chromium, which is toxic and regulated. Trivalent chromium coatings are a safer, eco-friendly choice.

Applications of Chromate Coatings:

- Aerospace

- Electronics

- Military

Anodizing

Anodizing is a process that uses electricity to create a protective layer on aluminum. This layer helps prevent corrosion and makes the aluminum more durable.

Key Benefits of Anodizing:

- It resists corrosion effectively.

- It is very tough and can withstand wear.

- You can dye it in many colors.

Applications for Anodizing:

- Building structures

- Electronic devices

- Decorative items

Oxide Coatings (Black Oxide)

Steel, stainless steel, and iron use black oxide, which creates a thin magnetite layer (Fe3O4) on the surface.

Key Benefits of Oxide Coatings:

- It improves corrosion resistance when used with oil or wax.

- It reduces light reflection for a non-glare finish.

- It enhances the appearance with a sleek black color.

Applications of Oxide Coatings:

- Tools

- Firearms

- Machine Parts

Conversion Coatings for Magnesium

Magnesium is a lightweight and reactive metal used in the aerospace and automotive industries. Unique treatments such as Dow 17 or magnesium chromate are often used as coatings to prevent corrosion.

Key Benefits of Conversion Coatings for Magnesium:

- It protects magnesium from rust.

- It helps paints and sealants stick better.

Applications for Conversion Coatings for Magnesium:

- Aerospace

- Automotive

How to Choose the Right Conversion Coating?

Choosing the right conversion coating for your project involves several important factors. Consider these points to help you make your decision:

Type of Metal Substrate

The formulation of various conversion coatings is specific for different types of metals. For example:

- Use phosphate coatings for steel.

- Opt for chromate coatings or anodizing for aluminum.

- Consider black oxide for iron or steel.

Environmental Conditions

The environment your product will be exposed to plays a significant role in coating selection:

- For high-corrosion environments (e.g., coastal or industrial areas), prioritize coatings with superior corrosion resistance.

- For indoor applications, a less robust coating may suffice.

Regulatory Compliance

Compliance with environmental regulations is essential. For example:

- Hexavalent chromium coatings are effective but highly toxic and regulated in many regions.

- Consider eco-friendly alternatives, such as trivalent chromium coatings or phosphate-free options.

Aesthetic Requirements

If appearance is important, choose a coating that aligns with the desired finish:

- Anodizing offers a wide range of colors and a sleek finish.

- Black oxide provides a classic, matte black look.

Cost and Durability

Balance the cost of the coating with the expected lifespan and performance. While some coatings may have a higher upfront cost, they can save money in the long run by reducing maintenance and extending the product’s life.

A Quick Review of Conversion Coatings

Choosing the right conversion coating is crucial for your project’s success. Different coatings provide varying benefits, so finding one that meets your needs is essential. Here’s a breakdown:

- Phosphate coatings work well for steel and ferrous metals.

- Chromate coatings are best for aluminum and zinc alloys.

- Anodizing is ideal for aluminum when you need durability and good looks.

- Black oxide gives steel and iron a sleek, corrosion-resistant finish.

- Magnesium chromate works well for reactive metals like magnesium.

With the right conversion coating, you can improve the performance and lifespan of your metal parts while meeting your industry requirements.

FAQs

These coatings are a chemical process that enhances metal surface protection.

Conversion coatings can last several years, providing durable protection against corrosion and wear.

Conversion coatings protect metal surfaces from corrosion, wear, and other environmental factors, enhancing durability and extending the lifespan of components.