Precision and efficiency are key in manufacturing. Consider a few things when designing custom jigs and fixtures to improve operations and boost productivity. Custom jigs and fixtures can significantly enhance your production, whether you are producing small batches or large volumes. Join us to learn about these essential tools’ benefits, design factors, and real-world uses.

What are jigs and fixtures?

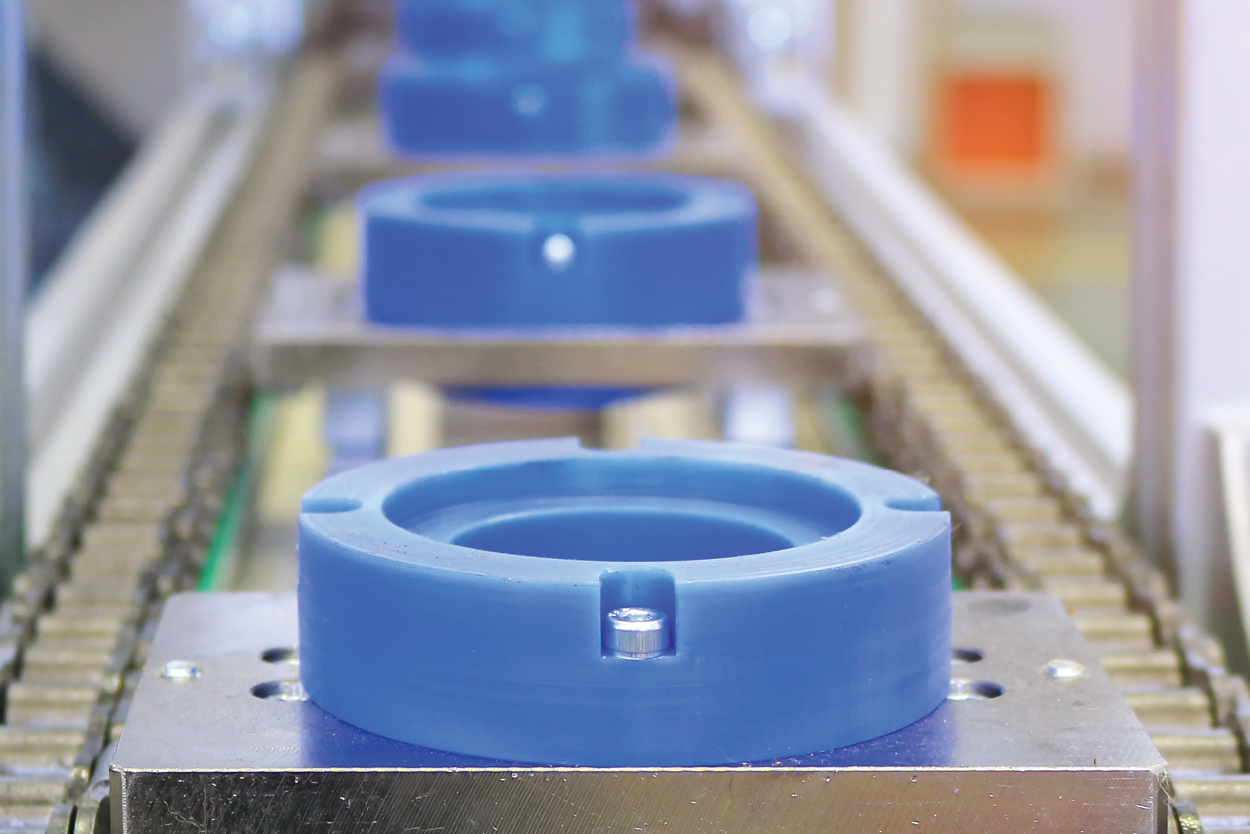

Jigs and fixtures are essential tools in manufacturing. They help ensure that things are made accurately and consistently, which saves time and effort. Jigs hold and guide a workpiece to allow for precise positioning. Fixtures secure the workpiece during manufacturing processes like machining, welding, or assembly. Using these tools improves the quality of the final product, lowers the chance of mistakes, and increases productivity by making the manufacturing process smoother. Learn more about the different types of jigs and fixtures.

Things to consider when designing jigs and fixtures?

Well-designed jigs and fixtures are crucial for efficient manufacturing. These tools help ensure consistent part quality, shorten setup times, and boost productivity on the shop floor.

As a skilled digital manufacturing partner, we have seen how a good jig or fixture can improve manufacturing workflows. This section will cover key points to consider when designing these crucial tools.

Functionality and Ergonomics

The main job of a jig or fixture is to hold a workpiece securely in the best position for machining or assembly. Good design can also improve how operators work. By using ergonomic principles, you can reduce fatigue and boost efficiency.

Accessibility and Visibility

Positioning clamping mechanisms, control interfaces, and part-loading areas carefully make the jig or fixture easy to use. It’s also essential to ensure that operators can see the workpiece. This visibility allows them to monitor the process and quickly spot any problems.

Modular and Adaptable Design

The ability to reconfigure or adapt a jig/fixture for different part geometries or production needs can unlock tremendous flexibility. Modular designs with standardized interfaces enable faster changeovers and reduce the need for custom solutions.

Material Selection

The materials you choose can impact your jigs and fixtures’ durability, thermal properties, and cost. Factors like part size, applied forces, and environmental conditions should all inform the material selection process.

Standard materials that are found in custom jigs and fixtures.

Jigs and fixtures are essential tools in manufacturing because they help maintain precision and consistency. Made from carefully chosen materials, these tools provide reliable performance over time.

In this section, we will examine some common materials used to make jigs and fixtures and discuss their unique properties and applications.

Aluminum

Aluminum is a valuable material often used to make jigs and fixture parts. Its light weight reduces the overall weight of the assembly, making it easier to handle and lessening stress on supporting structures. Aluminum resists corrosion and is easy to machine, making it a smart choice for many applications.

Steel

Steel is a common choice for jigs and fixtures requiring high strength and accurate dimensions. Different types of steel, like tool steel or stainless steel, can be used to fit the specific needs of your manufacturing process. This helps ensure the workpiece stays intact and the tools last longer.

ABS (Acrylonitrile Butadiene Styrene)

Acrylonitrile Butadiene Styrene (ABS) is a strong, versatile, and affordable plastic ideal for custom jigs and fixtures that require precision and reliability. Its lightweight nature and resistance to chemicals and temperature changes ensure durability in harsh conditions. Additionally, ABS is easy to shape, allowing for complex designs that enhance functionality and production efficiency.

PLA (Polylactic Acid)

PLA, or Polylactic Acid, is a commonly used material for making jigs and fixtures. It is biodegradable and renewable, which means it is better for the environment. PLA is also very stable, so it works well for precise manufacturing. Its low cost and easy processing make it a popular choice for custom jigs and fixtures.

PETG (Polyethylene Terephthalate Glycol)

PETG (Polyethylene Terephthalate Glycol) is an excellent material for custom jigs and fixtures. It is strong, durable, and flexible, making it suitable for various manufacturing tasks. PETG resists impacts, maintains its shape, and is easy to machine and finish. Whether you need detailed jigs or sturdy fixtures, PETG can enhance your production processes.

Nylon

Nylon is an excellent choice for jigs and fixtures because it is durable, low-friction, and corrosion-resistant. Its strength and light weight make it ideal for precision manufacturing, ensuring dependable and consistent results. Prototek specializes in additive manufacturing and CNC machining, allowing us to create high-quality nylon parts tailored to your specific needs.

Manufacturing methods for custom jigs and fixtures.

CNC Machining Custom Jigs and Fixtures

CNC machining is a great way to create custom jigs and fixtures. It offers high precision and repeatability, vital for making detailed and accurate parts. You can quickly build specialized workholding solutions that fit your specific manufacturing needs. CNC machining can improve productivity, enhance part quality, and streamline operations with custom jigs and fixtures.

Benefits of Machining Jigs and Fixtures

Custom-machined jigs and fixtures can significantly improve your manufacturing processes. Better tools can increase productivity, enhance product quality, and reduce waste. Precision fixtures help align and position parts consistently, which leads to tighter tolerances and better repeatability. Most importantly, these customized solutions reduce manual handling, prioritize safety, and boost efficiency on the shop floor. With Prototek’s manufacturing capabilities, we can quickly create custom jigs and fixtures that match your needs, helping you streamline your operations and stay competitive.

3D Printing Custom Jigs and Fixtures

3D printing is a fast and flexible way to manufacture custom jigs and fixtures. You can quickly design and make specialized tools for specific tasks, whether you need just one or a few. Improving your workflow boosts productivity and lessens dependence on expensive, generic solutions.

3D-printed jigs and fixtures can be light and strong, allowing for complex designs and on-demand production. Giving you an edge by increasing efficiency and precision on the factory floor.

Benefits of 3D Printing Custom Jigs and Fixtures

3D printing is a practical and cost-effective way to create custom jigs and fixtures that improve manufacturing processes. This method allows you to quickly produce specialized tools, reducing downtime and allowing you to design complex shapes that meet your needs. Additionally, 3D-printed jigs and fixtures usually cost less than traditional tools, offering a smart way to lower overall expenses while improving workflow, increasing repeatability, and using materials more efficiently.

Additionally, 3D-printed jigs and fixtures usually cost less than traditional tools, lowering overall expenses. Custom tools improve workflow, increase repeatability, and help you use materials more efficiently.

Enhance your manufacturing capabilities by partnering with Prototek Digital Manufacturing. Our expertise in designing and creating custom jigs and fixtures can significantly improve your operations. Let us help you streamline your processes and stay competitive in the ever-evolving manufacturing landscape.

Finding the right partner for manufacturing custom parts.

At Prototek, we know how important it is to have precise and reliable custom jigs and fixtures. Our experienced engineers and skilled technicians work hard to provide high-quality solutions that fit your needs. We use advanced methods such as additive manufacturing, CNC machining, and sheet metal fabrication to create great accuracy and efficiency in your designs. You can count on Prototek to help you make custom jigs and fixtures to improve your manufacturing processes.

FAQs

Jigs and fixtures hold and guide workpieces during manufacturing processes.

Jigs guide the workpiece, while fixtures hold it in place. Jigs ensure accurate part positioning, fixtures provide stability during machining.

Jigs and fixtures are manufactured through precision machining, 3D printing, and sheet metal fabrication ensuring accurate part alignment and repeatable production.