CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

Understanding CNC Machining

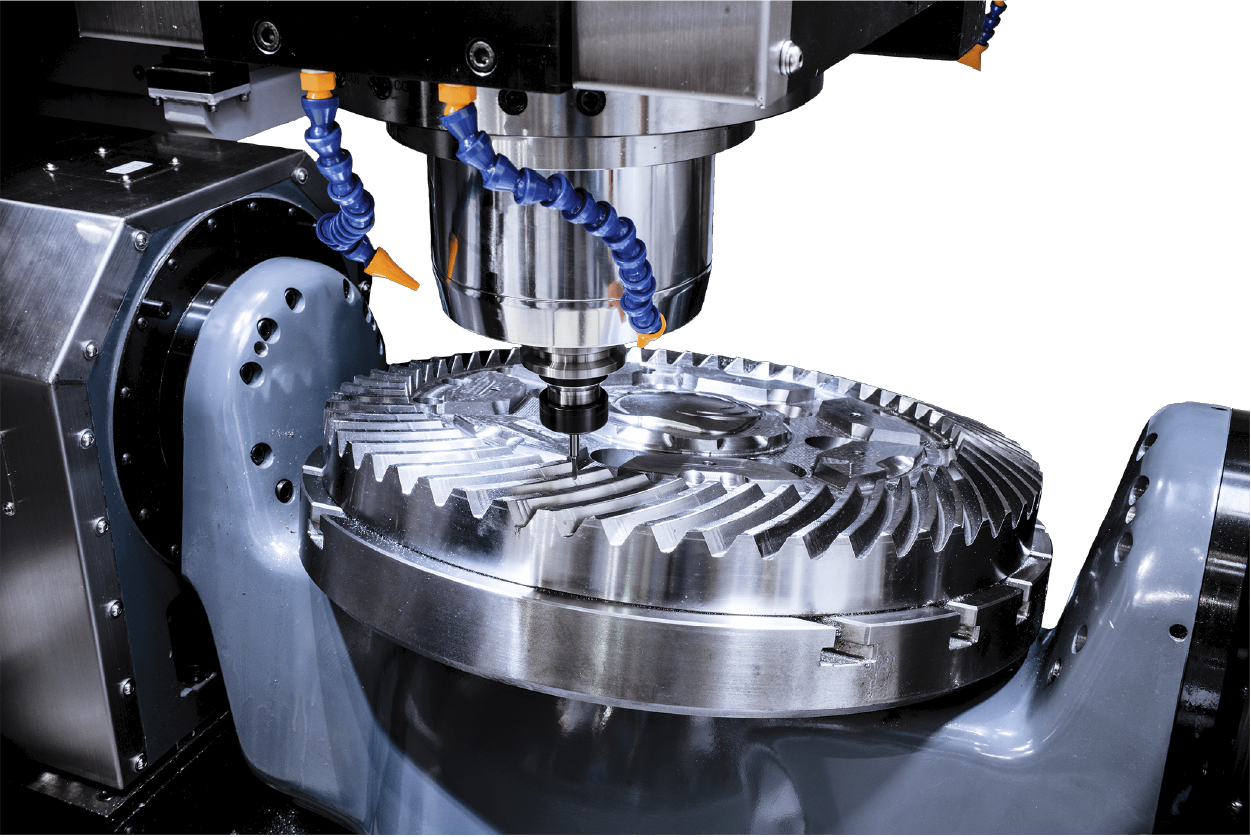

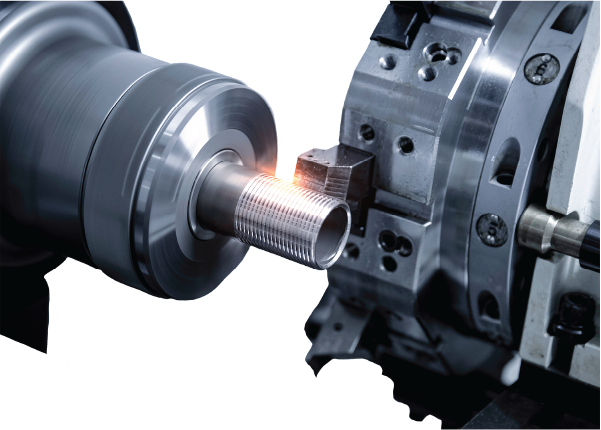

CNC machining is a subtractive manufacturing process that utilizes pre-programmed computer software to control the precise movement of tools and machinery. This process enables the accurate creation or modification of parts and components by removing material from a workpiece. Moreover, CNC machines can work with various materials, including metals, plastics, and composites, making them highly versatile in manufacturing.

Benefits of CNC Machining

Precision and Accuracy

CNC machines offer incredibly high precision and accuracy, often within thousandths of an inch, which is challenging to achieve through manual machining. This level of precision is crucial for industries like aerospace, automotive, and medical devices, which require complex and intricate components. Moreover, this precision is essential for maintaining the quality and reliability of the end products.

Increased Efficiency and Productivity

CNC machining significantly reduces production times and improves efficiency by minimizing human error and the need for manual intervention. Additionally, the automation of CNC processes enhances safety for machinists compared to manual methods.

High Quality

CNC machining processes ensure that every part we produce meets the highest standards of excellence. Our state-of-the-art equipment, coupled with the expertise of our skilled technicians, allows us to deliver parts with unparalleled consistency and repeatability. This quality advantage translates to increased reliability, tighter tolerances, and superior performance for our clients, making CNC machining a cornerstone of our comprehensive manufacturing capabilities.

Cost Effectiveness

CNC machining is a highly efficient manufacturing process, significantly reducing waste and production costs. This is achieved through the use of computer-controlled machines that enhance product precision, improve efficiency, boost profit margins, and increase overall market competitiveness.

Benefits of CNC Machining: Applications

CNC machining is essential in various aerospace, automotive, electronics, and medical industries. It is crucial for creating precise parts for aircraft, custom vehicle components, implants, and surgical tools. The ability to produce parts with tight tolerances ensures consistency and high-quality output, which is vital for these sectors.

CNC machining has become a crucial tool in modern manufacturing, from intricate aerospace components to custom automotive parts. Its ability to produce complex geometries, tight tolerances, and exceptional surface finishes has made it a go-to solution for various industries.

In the medical field, CNC machining plays a crucial role in fabricating orthopedic implants, surgical instruments, and prosthetic devices, ensuring the highest levels of accuracy and patient safety. Similarly, in the electronics industry, CNC machining is used to create intricate circuit board components and housings, enabling cutting-edge technology development.

The versatility of CNC machining extends to the world of consumer goods, where it manufactures everything from high-end furniture to custom-designed jewelry. Its precision and repeatability make it an ideal choice for producing unique, one-of-a-kind products that meet the demands of discerning customers.

As the manufacturing landscape continues to evolve, CNC machining remains at the forefront of innovation, offering businesses the tools they need to stay competitive and meet their customers’ ever-changing needs.

Emerging Trends in CNC Machining

Integration with AI and IoT

Incorporating artificial intelligence and machine learning into CNC machines is a growing trend. AI algorithms can optimize machining processes, predict tool wear, and detect potential defects in real time. Additionally, the integration of IoT technology has revolutionized monitoring and maintenance, providing continuous data feedback on machine parameters.

Advanced Techniques

New techniques such as multi-axis machining, high-speed machining, and hybrid CNC systems have emerged, enabling the production of complex parts with greater efficiency. These advancements have significantly improved the machinability of advanced materials and enhanced the overall quality of CNC operations.

Automation and Real-Time Monitoring

Using real-time monitoring and adaptive control systems allows CNC machines to adjust operations dynamically based on real-time feedback, further enhancing precision and efficiency.

Are you ready to start your project?

FAQs

CNC machining is a highly precise manufacturing process that uses computer-controlled machines to shape and fabricate various parts and components.

CNC machines come in various types, including mills, lathes, routers, and EDM machines, each designed for specific manufacturing needs.

At Prototek, we can CNC machine various materials, including metals, plastics, and composites.

CNC machining offers a wide range of finishing and post-processing options that can significantly enhance the final quality and functionality of the machined components. To learn more specifics, check out our post on Prototek’s Machine Shop Finishes, An Overview.