Sheet metal fabrication is not just a method but a life-saving process in the medical industry. It creates essential parts and devices, such as surgical instruments, equipment housings, and medical components, crucial for patient care and recovery.

The precision and flexibility of sheet metal fabrication in the medical industry make it an indispensable tool for creating medical products. This blog post will delve into its role in the industry, its applications, and its five main benefits, showcasing the importance of your skills in this field.

What is the importance of sheet metal fabrication in the medical industry?

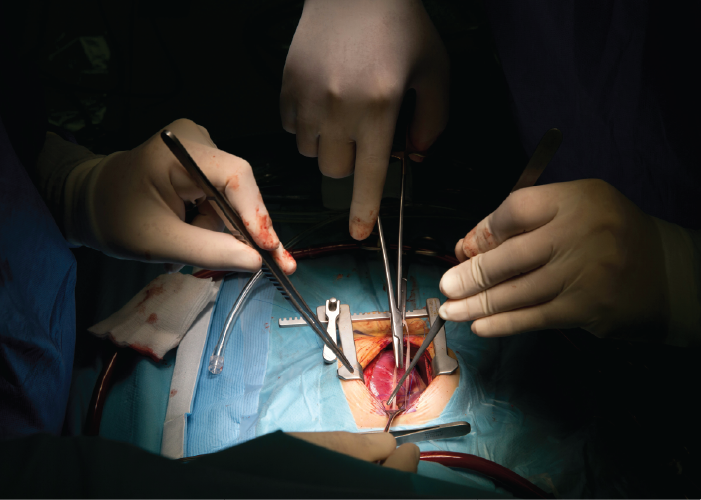

Sheet metal fabrication is an essential process in the medical industry. It creates parts for various devices, including surgical tools and imaging equipment. This process shapes and cuts metal sheets into strong, cost-effective pieces that meet strict healthcare standards. As a result, it plays a key role in producing life-saving medical devices.

Requirements for Medical-Grade Sheet Metals

Before choosing materials, it is crucial to thoroughly understand the specific needs for sheet metal used in medical settings. These needs ensure that the materials are safe for patients, underscoring the gravity of your decisions in this field.

Biocompatibility

The materials must be non-toxic and not cause harmful reactions when they touch the body. They should not trigger immune responses or cause inflammation, so thorough testing is necessary before using them in medical devices.

Corrosion Resistance

The materials must resist corrosion to withstand frequent sterilization, such as autoclaving and potent cleaning agents. This resistance helps protect medical instruments and devices from damage over time.

Durability

The materials must be strong enough to handle regular use and resist mechanical stress without breaking or bending. They should endure impacts repeated movements, and wear over time to stay safe and functional.

Hygiene

Materials’ surfaces must be smooth and easy to clean, helping reduce bacteria and prevent infections. A good surface finish ensures that sanitizing medical instruments can be effective and safe.

By following these critical requirements, manufacturers can ensure that the sheet metals used in medical applications are safe and effective.

Sheet metal materials used in medical applications.

Stainless Steel

Stainless steel is ideal for the medical industry because of its excellent properties, making it suitable for many applications.

Common Grades:

- 304 stainless steel is a common choice in the medical field because it resists corrosion well. It works well for many medical uses and is easy to shape, which helps create complex surgical tools and equipment.

- 316 stainless steel resists corrosion and can handle harsh chemicals and strong sterilization methods used in healthcare. This type of steel is excellent for making surgical tools and implants because it withstands the harsh conditions in surgical settings.

Medical Applications:

- Stainless steel is excellent for making surgical tools like scalpels and forceps. It is durable and easy to keep sterile.

- Stainless steel is an outstanding choice for medical enclosures and cabinets because it resists corrosion and is easy to clean. Making it ideal for storing medical supplies and helping keep medical facilities safe and hygienic.

- Stainless steel is a popular choice for orthopedic implants because it is strong and works well with the body. Making the implants long-lasting and reliable for surgeries.

- Hospital furniture, like beds and trolleys, is typically made from stainless steel. This strong material helps keep surfaces clean and hygienic.

Why It’s Ideal: Stainless steel is essential in healthcare because it does not rust and can stay clean and smooth. These qualities help keep patients safe and ease infection control, making stainless steel a key material in modern medical facilities.

Aluminum

Aluminum is commonly used in medicine because it is lightweight and does not rust. It works well for many medical devices.

Key Benefits:

- Lightweight: Aluminum is light, which makes it easy to handle and transport medical equipment. It is crucial in emergencies when speed matters.

- Aluminum does not attract magnets. It is essential because it helps protect sensitive medical equipment, like MRI machines, from disruption caused by magnetic materials.

Medical Applications:

- We make strong, lightweight aluminum cases for diagnostic equipment like ultrasound machines and imaging systems. These enclosures protect sensitive parts and improve the devices’ appearance.

- Aluminum is strong and lightweight, making it an excellent choice for wheelchair frames. Users can move their chairs quickly, and the frames can handle daily use safely and comfortably.

- Aluminum is helpful for surgical tools like clamps, forceps, and trays because it is lightweight and strong. Helping doctors perform surgeries more quickly and accurately, reducing fatigue during extended operations.

Why It’s Ideal: Aluminum is easy to shape and finish, which allows for custom parts that are strong and smooth. This feature improves how well they work and keeps things hygienic, making cleaning easier. Because of these advantages, aluminum is a practical choice for medical uses.

Titanium

Titanium is an essential material in medicine because it is strong, lightweight, and works well with the body. These qualities make it a popular choice for many uses.

Advantages:

- Titanium is strong against corrosion and wear. It can handle bodily fluids and environmental factors well, helping it last long, even in harsh biological conditions where other materials might fail.

- Titanium works well with human tissue, making it an excellent choice for long-term implants. This compatibility lowers the chances that the body will reject the implant and helps it function properly inside the body.

- Titanium is safe for everyone, including those sensitive to other metals or who have allergies. It is nontoxic and hypoallergenic, making it suitable for different patients.

Medical Applications:

- Surgical implants, such as hip and knee replacements and dental implants, are often made from titanium. Titanium is strong and can bond well with the surrounding tissue, helping ensure successful surgeries that last a long time.

- Titanium is strong and lightweight, making it an ideal material for comfortable and functional prosthetic limbs. It helps users stay active and enjoy fulfilling lives.

- Titanium is an excellent material for surgical instruments. It is strong and lightweight, which helps surgeons perform delicate operations more efficiently.

Why It’s Ideal: Titanium is strong, lightweight, and safe for the body, making it essential in designing advanced medical devices. These traits help ensure that medical devices are reliable and long-lasting, making titanium necessary in modern medicine.

Copper and Its Alloys

Copper and its alloys, including brass and bronze, are increasingly employed in various medical applications due to their unique germicidal properties.

Key Features:

- Copper and its alloys kill bacteria and viruses on contact. This action helps reduce harmful pathogens significantly.

- These materials have excellent electrical conductivity, making them suitable for medical devices where reliable power transmission is essential.

Medical Applications:

- Copper is ideal in hospitals and healthcare facilities on surfaces many touch, such as doorknobs, handrails, and bed frames—reducing the risk of germs spreading between patients and staff.

- Copper is commonly used to make electrical parts in medical devices. Ensuring safety and efficiency in diagnostics and treatments.

- Copper-infused surfaces are used in sterile workstations to make them cleaner and safer for medical procedures.

Why It’s Ideal: Copper’s natural antimicrobial properties effectively reduce infection risks, making it an excellent choice for places where many people come into contact with surfaces. Using copper also helps improve patient safety and health outcomes in medical settings.

Nickel Alloys

Nickel-based alloys play a vital role in specialized medical applications where their durability and corrosion resistance are paramount.

Properties:

- These alloys can withstand high heat and harsh chemicals. Making them suitable for various medical settings, even in extreme conditions.

- Nickel-based alloys stay strong and work well, even under heavy stress, ensuring they last a long time.

Medical Applications:

- Medical implants, like those used in hip and knee replacements, are made from special alloys. These alloys help the body accept the implants with less chance of rejection.

- Surgical tools made from nickel-based alloys stay sharp and resist wear. It gives surgeons the precision and durability they need during procedures.

- Heat-resistant materials are essential in sterilization equipment. They help keep the sterilization processes effective, ensuring the equipment remains safe and sterile for medical use.

Why It’s Ideal: Nickel-based alloys are a top choice for medical environments because they are strong, durable, and corrosion-resistant. These qualities make them reliable and safe for critical applications.

Cold Rolled Steel (CRS)

Cold-rolled steel (CRS) is not often associated with medical uses, but it is vital for the structural parts of healthcare facilities. Its strength and cost-effectiveness make it essential in building durable medical environments.

Advantages:

- CRS is a cost-effective choice compared to materials like stainless steel or aluminum. It offers a more affordable option while still maintaining good quality.

- CRS is strong and consistent in thickness, making it an excellent choice for applications that need dependable support and stability.

Medical Applications:

- Support Structures for Medical Equipment: CRS is widely used to build frames that hold heavy medical devices, ensuring they stay secure and stable during use.

- The company makes frames for medical equipment that do not need to interact directly with patients, such as carts and storage units.

Why It’s Ideal: CRS is a strong and durable material that is also cost-effective. It works well in settings where it will not touch patients and where biocompatibility does not matter. Its ability to handle the demands of busy healthcare environments makes it a reliable choice for various structural uses.

Are you ready to start your project?

FAQs

Medical devices, surgical instruments, and equipment housings are common sheet metal fabricated parts for the medical industry.

Stainless steel, titanium, and aluminum are common sheet metal materials in the medical industry for their durability and corrosion resistance.

Strict quality control, material traceability, and rigorous testing to ensure sterility and durability of medical sheet metal parts.