All About Anodizing Aluminum

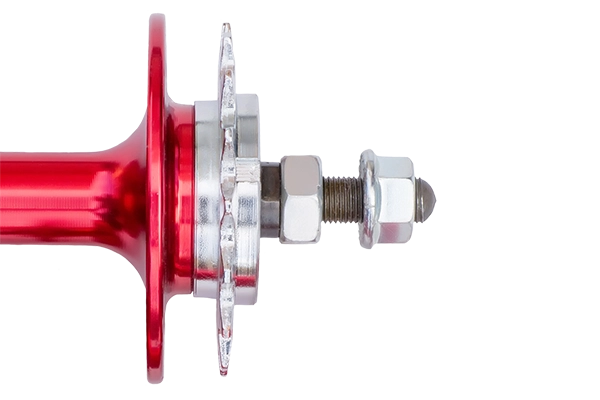

Anodizing is a valuable process for finishing aluminum parts. It uses a mild acid to improve the natural oxide layer on aluminum, making the parts more substantial and attractive. The anodic layer protects the metal from damage and wear, allowing creative designs.

You can dye anodized aluminum parts, which gives you many color options. There are three main types of anodizing: Type I, Type II, and Type III. This article will explain how anodizing works, its benefits, and its limitations, especially regarding how it creates appealing finishes.

The Process of Anodizing Aluminum

Understanding the anodizing process is crucial. To anodize aluminum, follow these four steps:

1. Pretreat the aluminum component.

Start by giving the aluminum part a shiny or satin finish in a well-ventilated area. You can use light etching for a satin finish or a solution of phosphoric and nitric acid for a glossy finish.

To improve anodizing, ensure the aluminum surface is smooth. Clean the aluminum by soaking it in a grease-removal solution, such as mild detergent or a commercial degreaser. Then, rinse it with hot water.

2. Anodize the aluminum component.

Connect the aluminum part to a power source to start anodizing. Carefully dip the part into the anodization bath—a 1:1 solution of distilled water and battery acid (sulfuric acid). Run the power supply to your aluminum for 45 minutes, then turn off the power and remove the component from the solution.

Pay attention to important factors such as the solution composition, temperature, current density, voltage, and time. These factors determine the quality of the anodized part.

3. Coloring the aluminum component.

After anodizing, you can dye the aluminum part for your preferred color. To do this, soak the anodized aluminum in a metal salt solution while applying an electric current. The soaking time and the solution’s ingredients will affect the final color. Typically, the aluminum stays in the dye for about 15 minutes. Standard color finishes include:

- Gold

- Black

- Transparent

- Brown

- Bronze

- Nickel

- Other colors are available

If you need a specific color for your project, please contact our team!

4. Sealing the aluminum component.

Seal the aluminum part to prevent corrosion and leaks. You can choose between two sealing methods: cold sealing or heat sealing.

Dip the part in a nickel acetate solution at room temperature for cold sealing, or boil it in deionized water for heat sealing.

The goal is to protect the surface from scratches and stains, increasing the part’s durability and lifespan.

Types of Anodizing

Different anodizing processes, like sulfuric acid, hard coat, and chromic acid, provide specific benefits for various uses. Understanding these processes helps you choose the best type of anodizing for your needs. Sulfuric acid anodizing is cost-effective and versatile. Hard coat anodizing is durable, offers strong wear resistance, and is suitable for insulation.

1. Anodizing I - Chromatic Acid Anodizing

Chromic acid anodizing, or type I anodizing, creates a thin oxide layer between 0.00002 and 0.0001 inches thick. This layer protects against corrosion when appropriately sealed, similar to thicker anodized layers. However, because it is thin, it does not hold dye well, resulting in a grayish finish that may not be desirable for decoration. You can dye it black for use in protective optical components. Chromic acid anodizing is effective and provides long-lasting, bright finishes on aluminum. This method is commonly used in aerospace and welded parts because it creates strong adhesive bonds.

2. Anodizing II - Sulfuric Acid Anodize

3. Anodizing III - Hardcoat Anodizing

Hardcoat anodizing creates a thick, strong oxide layer that protects against wear and insulation. This process makes the surface non-conductive and guards against wear, corrosion, and damage. You can trust its durability for your components.

8 Benefits of Anodizing Aluminum

1. Better Adhesive Bonding

Anodizing aluminum creates a strong oxide layer that helps it bond better, meaning the assemblies last longer and are more substantial. It also makes aluminum more resistant to corrosion and wear. Because of these benefits, aluminum is a reliable choice for many applications.

2. Attractive Aesthetics

Anodized aluminum looks good and adds style to products. This process makes the material strong, resistant to rust, and able to handle wear and tear. Anodization can create different finishes, like matte, glossy, and metallic. The result is a hard surface that resists scratches and can endure harsh conditions. Anodized aluminum is a valuable choice for many industries.

3. Greater Corrosion Resistance

Anodized aluminum protects against corrosion and damage, making it last longer. This coating extends the aluminum’s life and makes it more resistant to wear and chemicals.

4. Cost-Efficient

Anodizing is a process that makes aluminum stronger by adding a protective layer of oxide. We soak the aluminum in an acid solution and pass an electric current through it. This oxide layer helps the aluminum resist wear and corrosion. It also keeps the color when dyed. Anodizing lowers maintenance needs and increases the lifespan of aluminum parts.

5. Enhanced Durability

Anodizing makes aluminum parts stronger and helps them last longer. It also better resists wear and tear and is less likely to corrode from moisture, air pollution, and other environmental factors.

6. Excellent Electrical Insulation

Anodizing improves aluminum’s electricity insulation by adding a protective oxide layer that reduces electrical conductivity. Electronic circuits and power systems use this finishing process, especially in harsh environments where reliability matters most.

7. Environmental Sustainability

Anodizing aluminum is a safe and affordable way to make it more durable. This process creates a strong oxide layer that protects the aluminum from damage, rust, and wear. Industries like aerospace and consumer electronics often use anodized coatings. Anodizing also uses sustainable materials and practices, which helps lower its environmental impact. These advantages make anodized aluminum an excellent option for manufacturers and consumers.

8. Better Paint Adhesion

Anodizing helps paint stick to aluminum, creating a strong finish that resists weather and corrosion. It protects against scratches and abrasions, making it great for various uses like buildings, aerospace, and electronics. Anodized aluminum works well indoors and outdoors, making it a good choice for lasting projects.

Anodized aluminum is strong and resistant to scratches and abrasions. Making it an excellent choice for many uses, such as buildings, aerospace, and electronics. It works well indoors and outdoors, making it a wise investment for projects that must last a long time.

Are you ready to start your project?

FAQs

Anodizing is a process that improves metal surfaces by adding a strong oxide layer. This layer makes the metal more durable and resistant to corrosion, and it also makes the metal look better. Anodizing is a practical and cost-effective option for many industries.

To anodize aluminum, follow these steps:

- Clean the Aluminum: First, wash the aluminum to remove any dirt or grease.

- Soak and Anodize: Next, soak the aluminum in an electrolytic solution and use electric current to create an oxide layer.

- Rinse and Color: After that, rinse the aluminum dyes or sealants for different finishes.

- Seal the Metal: Finally, seal the aluminum to protect it from corrosion and make it more durable.

Be careful when anodizing aluminum because it involves chemicals and electricity. Always follow safety guidelines for the best results.

Anodizing is a process that creates a strong, corrosion-resistant surface on aluminum, titanium, and some magnesium alloys. You can also add color to anodized materials to make them look better.

Anodized aluminum comes in various colors, such as silver, gold, bronze, black, blue, green, and red. This variety of colors allows for creative designs and unique products.

Anodizing and electroplating are two different processes. Anodizing creates a strong layer that resists corrosion, while electroplating adds a thin layer of metal to the surface.

Anodized aluminum has a smooth, even color. To see if aluminum is anodized, look for a consistent color and a slightly textured surface. Non-anodized aluminum looks dull and uneven.

Anodizing your component helps keep tight tolerances. Monitoring the process ensures that the size changes very little.