Automated

Post-Processing

Parts in days anywhere in the USA.

AMT’s automated post-processing vapor smoothing machines, PostPro SF100 and Pure, speed up the finishing process for SLS, MJF, and FFF.

- Smoothed Surface Finish

- Improved Mechanical Properties

- Time Efficient

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

* Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct certifications and registrations.

Table of Contents

What is Automated Post-Processing?

AMT PostPro’s state-of-the-art automated post-processing technology offers an innovative solution to overcome the limitations of traditional 3D printing. The technology employs a multi-step process that includes automated vapor smoothing, chemical polishing, and surface functionalization to improve printed parts’ surface quality, precision, and mechanical properties. The process is fully automated, reducing the need for manual labor and improving consistency across parts. Furthermore, the technology can handle various materials, including plastics and ceramics, making it a versatile solution for various industrial applications.

How Does Automated Post-Processing Work?

AMT PostPro has developed an advanced and sophisticated solution for automated post-processing that has revolutionized the world of 3D printing. This cutting-edge technology employs a multi-step process involving surface smoothing, chemical polishing, and surface functionalization to enhance printed parts’ quality, precision, and mechanical properties.

The surface smoothing process utilizes automated sanding and blasting techniques to eliminate any roughness, bumps, or other irregularities on the surface of the printed part. This step significantly improves the surface finish, enhancing the part’s aesthetics and functionality.

The chemical polishing process involves using chemical agents to remove residual material or impurities on the part’s surface. This step eliminates any surface defects and ensures the part is ready for the next step.

The surface functionalization process involves applying a thin coating to the part’s surface, which enhances its mechanical properties, such as strength, durability, and resistance to wear and tear. This process also enhances the part’s surface finish, making it more aesthetically pleasing.

The process is fully automated, reducing manual labor and ensuring consistency across parts. Furthermore, the technology can work with various materials, including metals, plastics, and ceramics, making it a versatile solution for various industrial applications.

In summary, AMT PostPro’s automated post-processing technology is a game-changer for 3D printing, providing an innovative solution that enhances printed parts’ quality and functionality while reducing costs and increasing efficiency. AMT PostPro’s state-of-the-art automated post-processing technology offers an innovative solution to overcome the limitations of traditional 3D printing. The technology employs a multi-step process that includes surface smoothing, chemical polishing, and surface functionalization to improve printed parts’ surface quality, precision, and mechanical properties. Since the process is fully automated, the need for manual labor is reduced, and consistency across parts is improved. Furthermore, the technology can handle various materials, including metals, plastics, and ceramics, making it a versatile solution for various industrial applications.

Prototek's Automated Post-Processing Capabilities

OEM:

AMT PostPro

Envelop Dimensions:

100 Liters

Machines:

PostProDP (Depowdering), PostPro SF 100, and PostPro SF100 Pure

Compatible Technologies:

Laser Sintering, Multi-Jet Fusion, and Fused Filament Fabrication

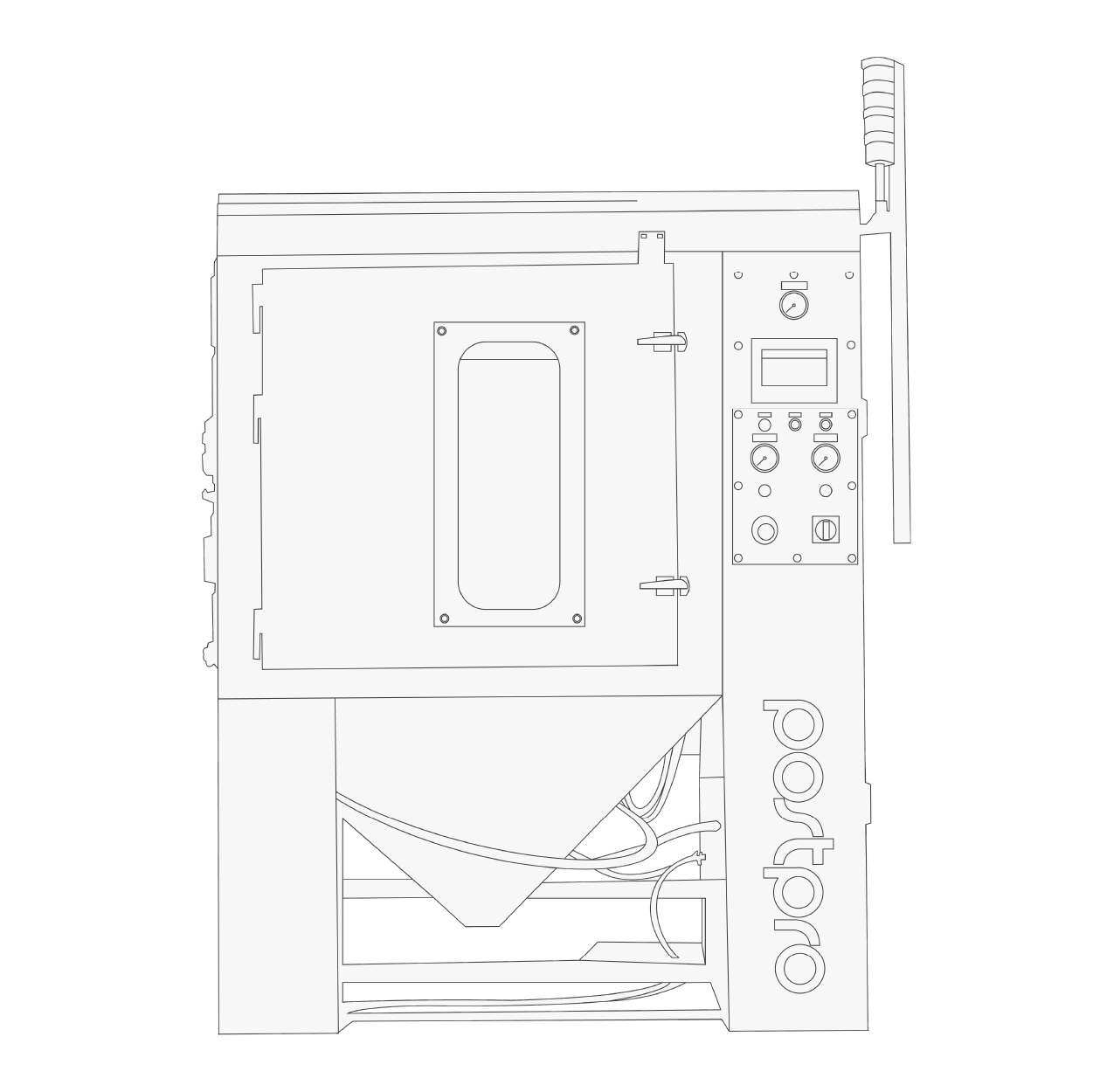

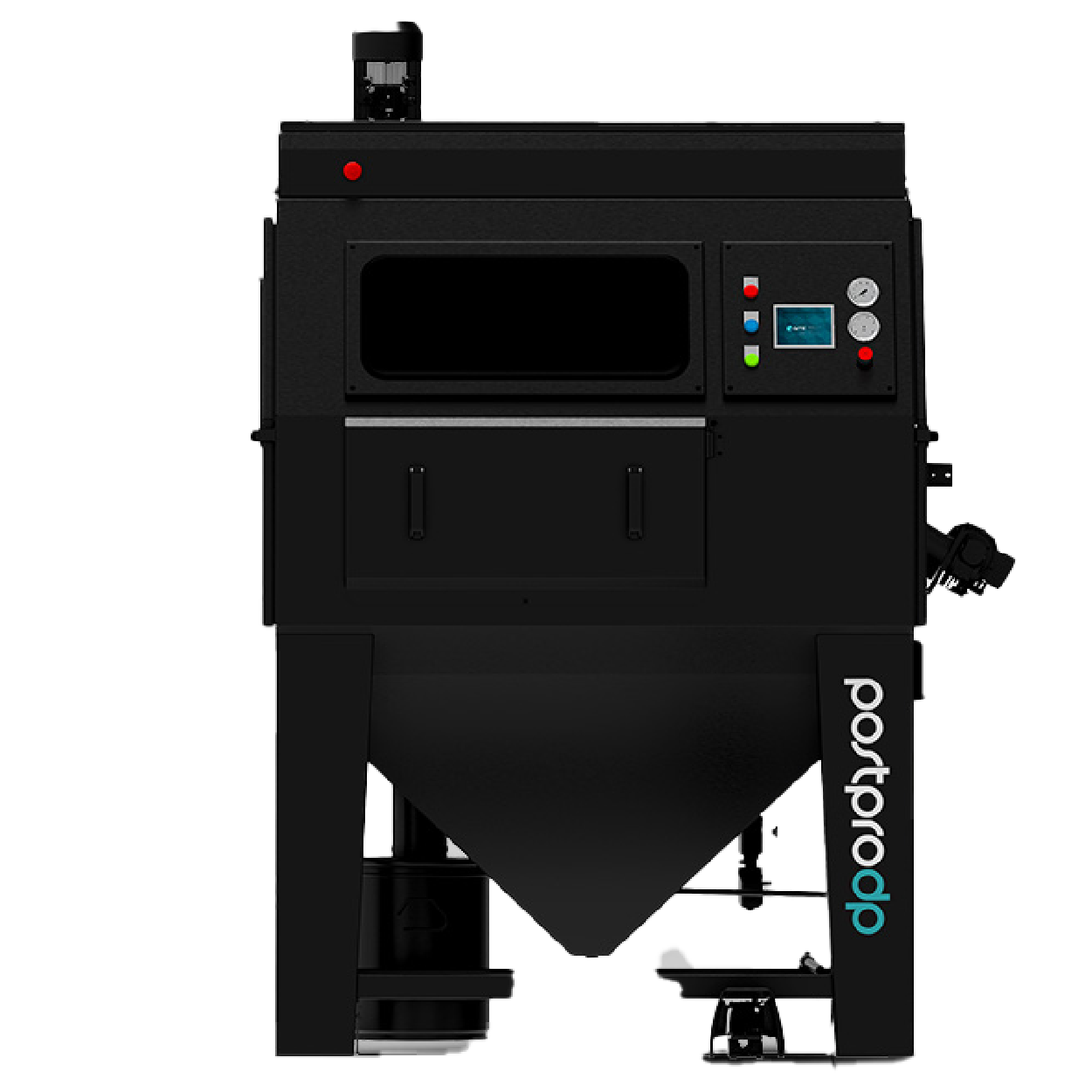

PostProDP - Depowdering

Depowdering is a crucial stage in 3D printing, particularly for powder-based technologies such as selective laser sintering (SLS) or multi-jet fusion (MJF). After printing, parts are covered in excess powder, which needs to be removed. Depowdering is a thorough process involving compressed air and depowdering media (usually glass beads) to ensure all residual powder is cleared without damaging the intricate details of the print. Correct depowdering is essential for the part’s functionality and prepares it for further post-processing steps, such as surface blasting or vapor smoothing.

The PostproDP’s automated depowdering system is a highly advanced and innovative technology that has revolutionized the powder-bed additive manufacturing processes. This system removes excess powder from the printing bed and improves the manufacturing process’s quality, accuracy, and efficiency. The automated depowdering system quickly and efficiently removes residual powder, ensuring a clean and safe manufacturing environment. It is a valuable asset to the entire process, reducing the time and effort required for manual depowdering while ensuring consistent and high-quality results. The PostproDP’s automated depowdering system is a game-changer for the powder-bed additive manufacturing industry, providing unprecedented precision, accuracy, and speed.

PostPro SF100

The PostPro SF100 machine manufactured by AMT is a cutting-edge industrial vapor smoothing machine designed explicitly for polypropylene. It is a highly advanced and precision-engineered machine that can transform vapor smoothing capabilities in the polypropylene market, offering unparalleled surface refinement and enhanced aesthetics for your 3D-printed applications.

With its state-of-the-art automated vapor smoothing technology, the PostPro SF100 provides a reliable and efficient solution for post-processing polypropylene parts, delivering a finished product with excellent finish quality and strength. The machine’s unique vapor smoothing process works by exposing the surface of the 3D-printed part to a vaporized solvent that melts and smooths the surface, removing any layer lines and imperfections.

The PostPro SF100 machine has a closed-loop system that ensures consistent and repeatable results, making it an ideal solution for components requiring high-quality surface finishes. The finished product has a smooth, glossy surface finish that is pleasing to the eye and tactilely appealing. With this machine, you can achieve remarkable finishes comparable to injection-molded parts.

The PostPro SF100 machine is perfect for components that require high-quality surface finishes for their 3D-printed parts. It can be used for various automotive, aerospace, medical, and consumer goods applications. It is a reliable and efficient solution that delivers consistent results.

PostPro SF100 PURE

The PostPro SF100 PURE is a high-performance system designed for vapor smoothing 3D-printed parts. It is the most advanced system in the AMT lineup, offering unparalleled results and superior finish quality. Prototek recently acquired the PostPro SF100 Pure version. This system has a 100-liter capacity, making it suitable for handling large parts.

The PostPro SF PURE is the latest generation of AMT PostPro’s industrial systems, developed to meet the demanding requirements of the additive manufacturing industry. It incorporates advanced features such as automated process control, closed-loop temperature and pressure monitoring, and digital controls for precise adjustments. These features ensure the system delivers consistent and reproducible results with minimal operator intervention.

The PostPro SF PURE is a state-of-the-art system offering best-in-class automated vapor smoothing capabilities. Its advanced, high capacity and safety features make it ideal for industrial-scale production of 3D-printed parts.

Advantages of Automated Post-Processing

- Smooth Surface Area

- Increased Durability

- Aesthetics

- Uniformity

- Watertight

- Improved Elongation @ Break

- Improved Tensile Strength

Why choose Prototek for your next project?

Are you looking for a reliable partner for your additive manufacturing project? Look no further than Prototek! With our cutting-edge technology and experienced team, we can deliver high-quality prototypes and end-use parts quickly and efficiently. Our services include additive manufacturing, CNC machining, sheet metal fabrication, casting and molding, and added-value services. You can trust us to provide personalized solutions to meet your unique needs while providing exceptional customer service. Choose Prototek for your next project and experience the difference firsthand. Contact us today to learn more!