Laser Cutting Overview

What is laser cutting?

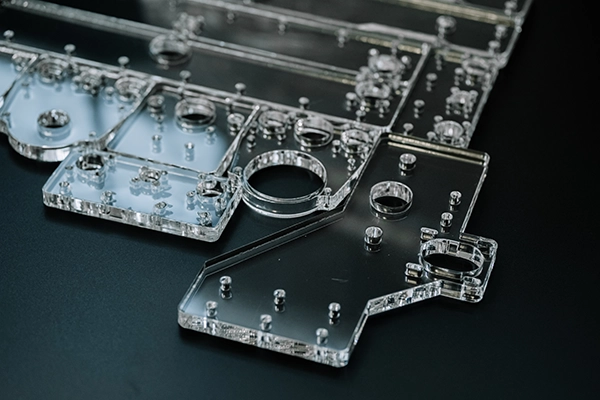

Laser cutting is an efficient way to manufacture items. It uses a focused laser beam to cut through materials like metals, plastics, wood, and rubber. This cutting method is a computer numerical control (CNC) process that helps create complex designs with high accuracy and consistency. Laser cutting has many applications in the automotive, aerospace, and electronics industries.

How does laser cutting work?

It is a precise method for cutting different materials. It uses a focused beam of light from a CO2 or fiber laser to melt or vaporize the material along the cutting line. This process allows for accurate and detailed designs and complex shapes.

Industries like aerospace, automotive, and electronics rely on laser cutting because it reduces waste, creates clean edges, and works with various material thicknesses. Its flexibility and ongoing improvements are significantly affecting the manufacturing industry.

Plasma Cutting Overview

What is plasma cutting?

Plasma cutting is a fast and accurate way to cut metal. It uses a high-temperature plasma arc to slice through different types of metals quickly. This method is often used in factories and manufacturing because it creates clean cuts with minor heat damage to the surrounding material.

How does plasma cutting work?

This process uses a high-temperature plasma arc to melt and remove metal, creating precise and clean cuts.

Plasma cutting often uses CNC machines, which follow programmed patterns to cut metal accurately. The process starts by compressing and ionizing a gas, like compressed air or nitrogen, to create the plasma arc. This gas flows through a small opening in the torch and onto the metal. The high heat melts the metal, and the fast-moving plasma blows away the molten material, resulting in a narrow, clean cut.

Plasma cutting, with its exceptional performance on thick, electrically conductive metals, is an innovative and cost-effective choice for industrial applications like fabrication and construction. Its efficiency with these materials makes it a practical and budget-friendly option for your projects.

Comparing Laser and Plasma Cutting

Laser cutting is a fast and effective way to make products using a focused beam of light. It can cut through different materials like plastics, rubber, and metals, which can be hard to cut with traditional methods. A CO2 or fiber laser creates the light that melts or vaporizes the material along the cut path. This precision allows for fine cuts, making it perfect for complex designs and patterns.

Many industries, including aerospace, automotive, and consumer electronics, use this cutting method because it is quick and accurate. It produces very little waste and can be automated to increase efficiency, which lowers costs and speeds up production.

Laser cutting is also flexible, allowing the creation of everything from simple shapes to detailed designs while maintaining high quality and consistency. Overall, it is a valuable tool for industries that require precise and efficient manufacturing.

Advantages of Laser and Plasma Cutting

Laser Cutting

Accuracy

A laser beam focuses energy on a small area, creating a narrow cut in the material. It is ideal for delicate cutting tasks that plasma cutters can’t handle.

Materials

Laser cutters can cut metal, wood, plastic, and ceramics, while plasma cutters can only cut conductive materials.

Speed

Laser cutters are faster and use less energy than plasma cutters, making them a better environmental choice.

Plasma Cutting

Cost

Plasma-cutting machines have lower operating costs.

Material Thickness

Plasma cutters can cut various metal plates up to 1.5 inches (38 mm) thick.

Low Maintenance

Plasma-cutting technologies need less upkeep and servicing than laser cutters because they are less precise and have a larger kerf.

Disadvantages of Laser and Plasma Cutting

Laser Cutting

Mirror-Like Materials

Laser cutting is not the best choice for shiny surfaces because the reflection can interfere with the cutting.

Material Thickness

Laser-cutting machines usually cannot effectively cut through materials thicker than 0.75 inches (19 mm).

Plasma Cutting

Wider Cut

Plasma cutting creates a broader cut, called kerf, which can make this method less accurate than others.

Suitable Materials

Plasma cutters work only with materials that conduct electricity, such as aluminum, steel, and copper. They cannot cut non-conductive materials like plastic or wood.

Is laser cutting or plasma cutting better for your project?

When deciding between plasma and laser cutting, it’s crucial to consider the materials you’ll be working with. The material’s thickness, conductivity, and stability will help determine the best cutting method. Also, consider the type of cuts you need—detailed designs or straight lines—because this will influence your choice. Lastly, keep the budget in mind. Laser-cutting machines usually cost more upfront than plasma-cutting machines, which is a key factor in your decision. Being well-informed about these factors will ensure you make the best choice for your project.

Are you ready to start your project?

FAQs

Laser cutting can accurately cut many materials, including metals, plastics, wood, and acrylic, making it a flexible manufacturing process.

Plasma cutting is a process that can cut through many types of materials. It works well on steel, stainless steel, aluminum, and other metals that conduct electricity.

Prototek Digital Manufacturing provides high-quality laser cutting services to create precise, custom parts. Our experienced team can work with many different materials to meet your needs, and we are committed to delivering parts quickly and efficiently.

At Prototek Digital Manufacturing, we provide reliable plasma-cutting services. Our skilled team offers cost-effective solutions for custom parts. We aim to exceed your expectations. Choose us for your plasma-cutting needs!

At Prototek, we focus on providing a smooth and customer-centered manufacturing experience. Our team of skilled professionals ensures that every step is efficient and tailored to your needs. We guarantee high quality in everything we do, from design to delivery, and we aim to exceed your expectations. With Prototek as your manufacturing partner, you can trust that we will do our best to deliver outstanding results for you and your business.