Casting Services:

Injection Molding

Our injection molding services offer the following:

- Accuracy - Including Surface Area

- Quick Lead Times

- Low to Medium-Volume Production Runs

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

What is Injection Molding?

Injection molding is a highly adaptable manufacturing process utilized to create a diverse array of parts and products. In this process, the material is heated until it becomes molten and then injected into a mold. Subsequently, the mold, typically made of metal, is designed to give the molten material a specific shape as it cools and solidifies. Generally, various industries use injection molding, including automotive, medical, and consumer goods. Moreover, it is a popular choice for producing high-volume parts and products due to its efficiency, speed, and accuracy.

In addition, injection molding uses materials such as thermoplastics, thermosets, and elastomers—automation for mass production or tailored for small-scale production. Furthermore, injection molding offers versatility and flexibility in design, making it a valuable tool in modern manufacturing.

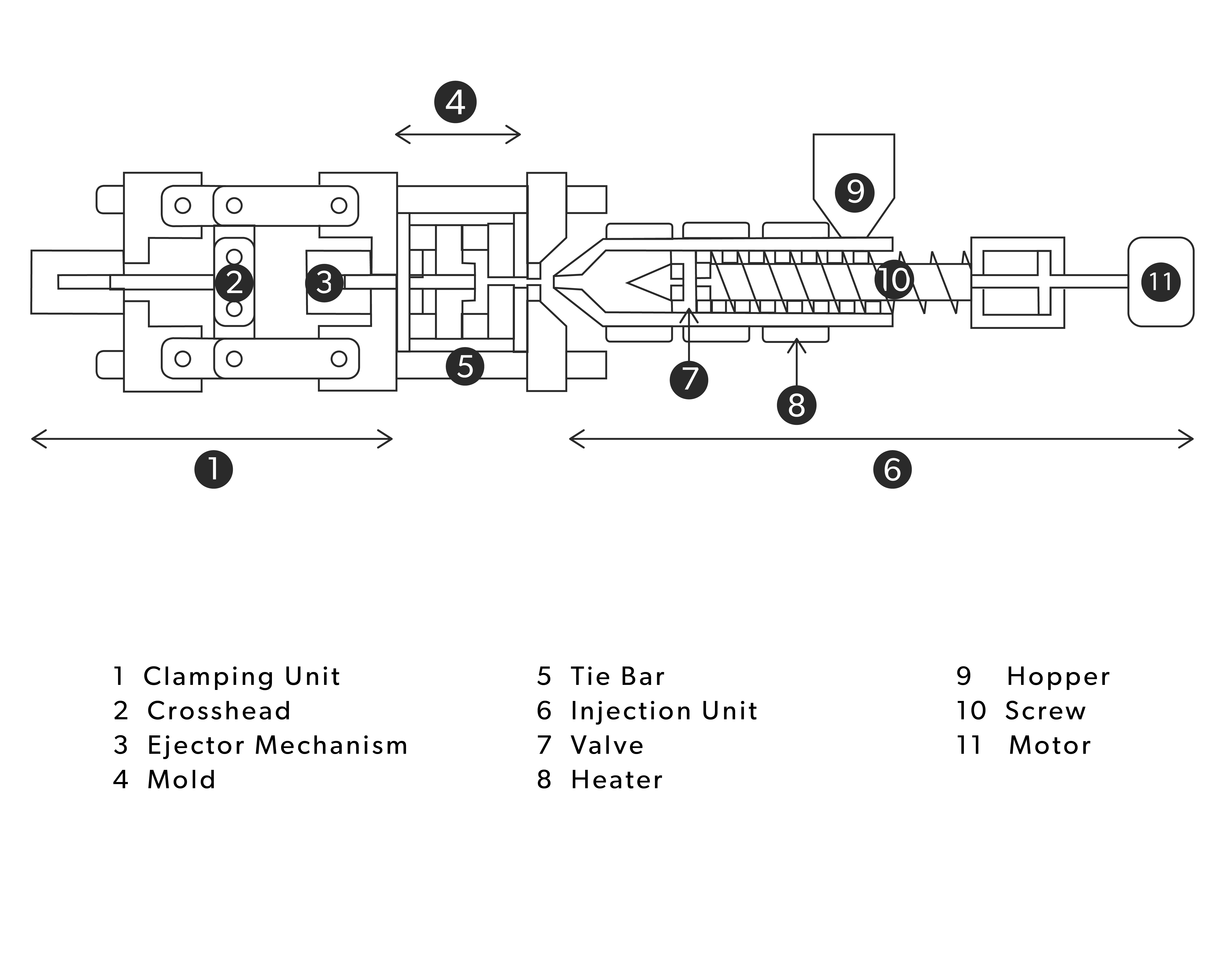

How does Injection Molding work?

Injecting molten material, usually plastic, into a mold cavity is the basis of injection molding, a commonly used manufacturing process. This process allows for producing complex shapes and designs with remarkable speed and accuracy. It offers high production rates consistent quality, and is highly customizable for large-scale production of high-quality plastic parts and products.

Injection Molding Process Steps

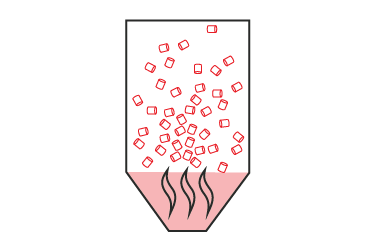

Step One: Melting Material

The raw material is uniformly fed into a hopper to initiate the injection molding. Subsequently, the material undergoes heating, ultimately leading to its melting.

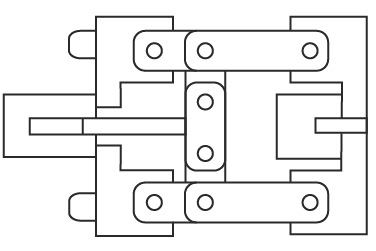

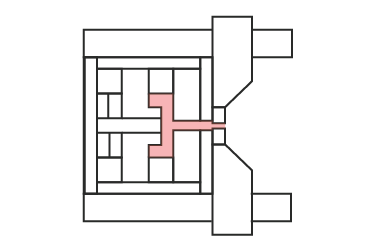

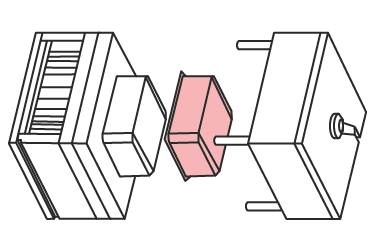

Step Two: Clamping

During the clamping phase of the injection molding process, the two metal plates of the mold are pressed against each other using a machine press. Fabricating injection molds are typically two clamshell-style pieces.

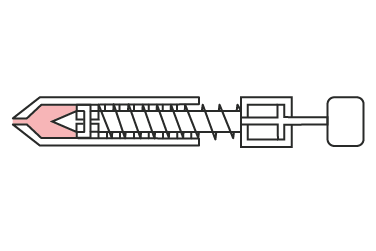

Step Three: Injecting the Material

The next step is injecting the melted material into the mold. The temperature of the molten material must remain consistent during this step.

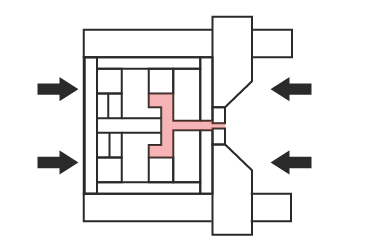

Step Four: The Application of Pressure

Additionally, pressure is meticulously applied directly to the mold to ensure that the liquid thoroughly fills each cavity, resulting in consistent components.

Step Five: Cooling the Material

The mold should be undisturbed to allow the hot plastic inside to cool and solidify into the final component.

Step Six: Opening the Mold and Removing the Final Product

After the part has cooled, a clamping motor slowly opens the two parts of the mold, allowing for the safe and simple removal of the final product. Subsequently, an ejector bar slowly pushes the solidified product out of the open mold cavity.

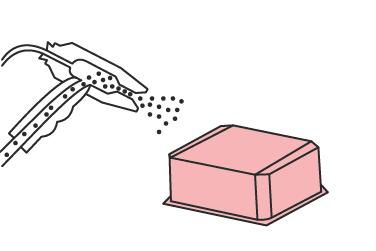

Step Seven: Post-Processing and Finishing

Afterward, the fabricator should use cutters to remove waste material and perfect the final product for customer use. Additionally, waste material can often be recycled and reused for the next part, reducing material costs.

Components of Injection Molding

Designing Parts for Molding

Designing parts for injection molding is a fascinating and rewarding process that demands meticulous attention to detail to achieve a successful outcome. In this process, designers must carefully consider various factors, including the materials’ properties, the geometry of the part, and other design considerations such as wall thickness, draft angles, and undercuts. Proper venting and gating are also crucial to ensure optimal mold filling and avoid defects like air traps or short shots. Designers should also consider the cost and feasibility of the mold and plan for post-processing and finishing operations. Successful design for injection molding requires a careful balance of these factors and often benefits from collaboration between designers, engineers, and experts.

Design Features

Bosses – The depth should be 30% of the wall thickness, and the edge groove should also be 30%. For structural integrity, they should be attached to side walls or ribs.

Drafts – A minimum angle of 0.5° or up to 5° for faces with textures.

Ribs & Gussets – Should have a draft and 40 – 60% of the thickness of outer walls.

Undercuts – Avoid using these if you can. These will add complexity and cost to your project.

Wall Thickness – Even wall thickness is recommended. Thinner walls will reduce costs and process time.

Things to Watch For

Drag Marks – Vertical walls in components with no draft angle are susceptible to getting marks on them when ejected from the mold.

Knit Lines – Miniscule lines form at the junction of two flows, causing discoloration and reduced component strength.

Sink Marks – Puckering or recesses caused by uneven solidification of the material. Thinner walls can help prevent these.

Injection Molding Finishes

Injection molding finishes enhance the appearance and function of molded parts through various techniques. These include adding texture to the mold, applying coatings, or using heat or pressure. Choosing the right finish requires considering factors such as use, material properties, and design. Working with molding experts is crucial to selecting the best technique that meets project goals while considering cost, production time, and tooling complexity.

Why choose Prototek for your next injection molding project?

Prototek offers high-quality plastic injection molding services tailored to fit any project’s needs. With over 30 years of experience in the industry, we have developed a reputation for delivering excellent results with fast turnarounds and competitive pricing. Our team uses state-of-the-art equipment and cutting-edge techniques to ensure that each project meets or exceeds customer expectations. We work closely with clients, providing guidance and support throughout the production process – from design to prototyping and full-scale production. Additionally, Prototek offers a wide variety of materials, including exotic materials, which are ideal for specialized applications. If you’re looking for a reliable partner to bring your next injection molding project to life, Prototek is the right choice.