Hardware inserts are versatile tools that are vital in manufacturing. They significantly enhance assembly functionality and durability. The various types available, each tailored for specific applications in manufacturing processes, demonstrate their versatility.

This blog post will explore the different types of hardware inserts, highlighting their benefits and ideal use cases.

First, when and why are hardware inserts necessary?

Inserts are essential in manufacturing because they provide extra strength, durability, and improved functionality.

They reinforce areas of parts that will experience high stress or wear over time. They can also add special design features, such as threaded holes or bearings.

By using inserts, manufacturers ensure that parts meet performance standards. This helps parts last longer and perform reliably in their intended uses.

Hardware inserts are essential for better design and function in mechanical applications, automotive parts, and consumer goods.

Types of hardware inserts.

Hardware inserts are small but essential in manufacturing and construction. They help secure, reinforce, and improve the performance of different materials and structures.

This section will explain the various types of inserts, each with its features and uses.

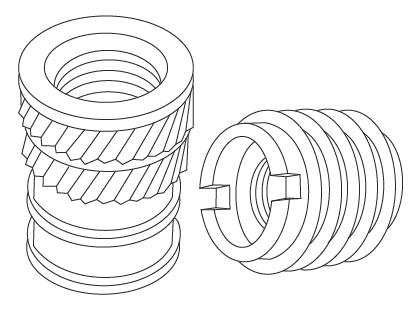

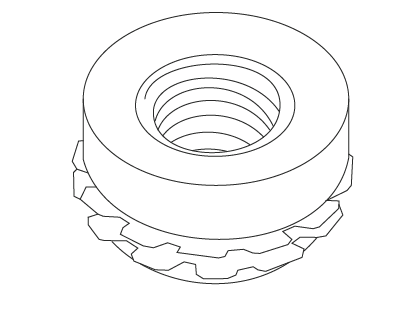

Threaded Inserts

Threaded inserts are round pieces that have internal threads. The inserts go in predrilled holes. These inserts provide a strong and reusable connection for screws or bolts. They are perfect for situations where you need to insert and remove screws or bolts many times.

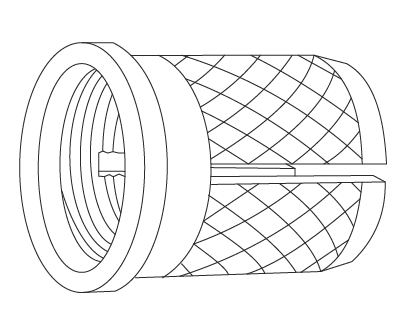

Press-Fit Inserts

Press-fit inserts, or interference-fit inserts, are designed to be pushed into predrilled holes. They create a tight and secure connection without additional fasteners or adhesives. These inserts are found in plates and other materials that require a strong and permanent joint.

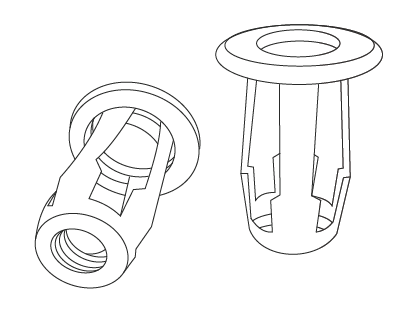

Expansion Inserts

Expansion inserts have a split design that helps them grip the inside of a predrilled hole. When you tighten a screw or bolt, the insert expands, creating a secure connection that resists vibration. These inserts work well in hollow or soft materials where traditional threaded connections may not be suitable.

Specialty Inserts

Specialty hardware inserts are designed for specific uses in addition to standard types. Some inserts work well in extreme temperatures, such as those found in space or deep-sea exploration, while others resist corrosion in harsh conditions, like those in chemical processing plants. Inserts with unique shapes or materials also exist to meet specific performance needs.

What are typical applications for hardware inserts?

Automotive

The automotive industry is essential for making vehicles functional and safe. A critical part is the inserts used in various vehicle parts, including engine components like cylinder heads and body panels like doors and hoods.

They provide a strong and secure way to assemble materials and components, reinforcing key areas of the vehicle. This not only boosts the strength of the parts but also significantly increases passenger safety and ensures the vehicle’s reliability. In short, hardware inserts are crucial for building high-quality cars that meet strict safety and performance standards.

Aerospace

The aerospace industry relies heavily on hardware inserts, which are used in various ways, such as in aircraft structures, avionics, and other critical systems.

Hardware inserts ensure safety and durability in aircraft manufacturing, including wing assemblies, fuselage sections, and control surfaces.

In avionics, they help securely attach and integrate electronic systems, improving the reliability of navigation and communication equipment.

By using hardware inserts, engineers can enhance performance and maintain the high safety standards needed in aviation.

Industrial & Construction

They are essential fasteners in construction and manufacturing that securely assemble machinery, equipment, and building materials.

They strengthen structural elements in construction, ensuring stability and longevity, while in manufacturing, they help produce equipment that can withstand extreme conditions.

Consumer Products

Hardware inserts are also found in consumer electronics, where they provide secure assembly for optimal performance and contribute to durability. They are crucial for safe and effective connections in various applications.

Are you ready to start your project?

FAQs

It is a specialized component embedded or attached to a product. It provides enhanced functionality, durability, or specific capabilities. These inserts are commonly used in manufacturing processes to improve performance and reliability.

Hardware inserts are essential components used in various manufacturing processes. Common types include threaded inserts, press-fit inserts, and expansion inserts. These inserts provide secure attachment points, enhance structural integrity, and enable the use of standardized fasteners in a wide range of applications.

Prototek’s diverse manufacturing capabilities allow the use of inserts in various processes, including additive manufacturing, CNC machining, sheet metal fabrication, and casting and molding. Our experts can help you find the optimal solution.