Chrome plating, also known as chromium plating, is a surface finishing technique in which a thin layer of chromium is electroplated onto a metal object. The result is a shiny, reflective surface that enhances the object’s aesthetic appeal and provides excellent resistance to corrosion, wear, and environmental degradation.

Various industries use chrome plating due to its numerous benefits. In the automotive sector, it is commonly used to coat vehicle trim, wheels, and bumpers, providing decorative and protective functions. In the aerospace industry, chrome plating protects components from harsh environmental conditions and ensures longevity. Additionally, consumer goods such as faucets, kitchen appliances, and decorative items often undergo chrome plating to achieve a visually appealing and durable finish.

Overall, chrome plating is a versatile and practical metal finishing process that offers aesthetic enhancement and superior protection, making it a popular choice in various applications.

Technology

CNC Machining and Sheet Metal Fabrication

Outcomes

The result is a shiny, reflective surface that enhances the object’s appearance and offers excellent resistance to corrosion, wear, and environmental damage.

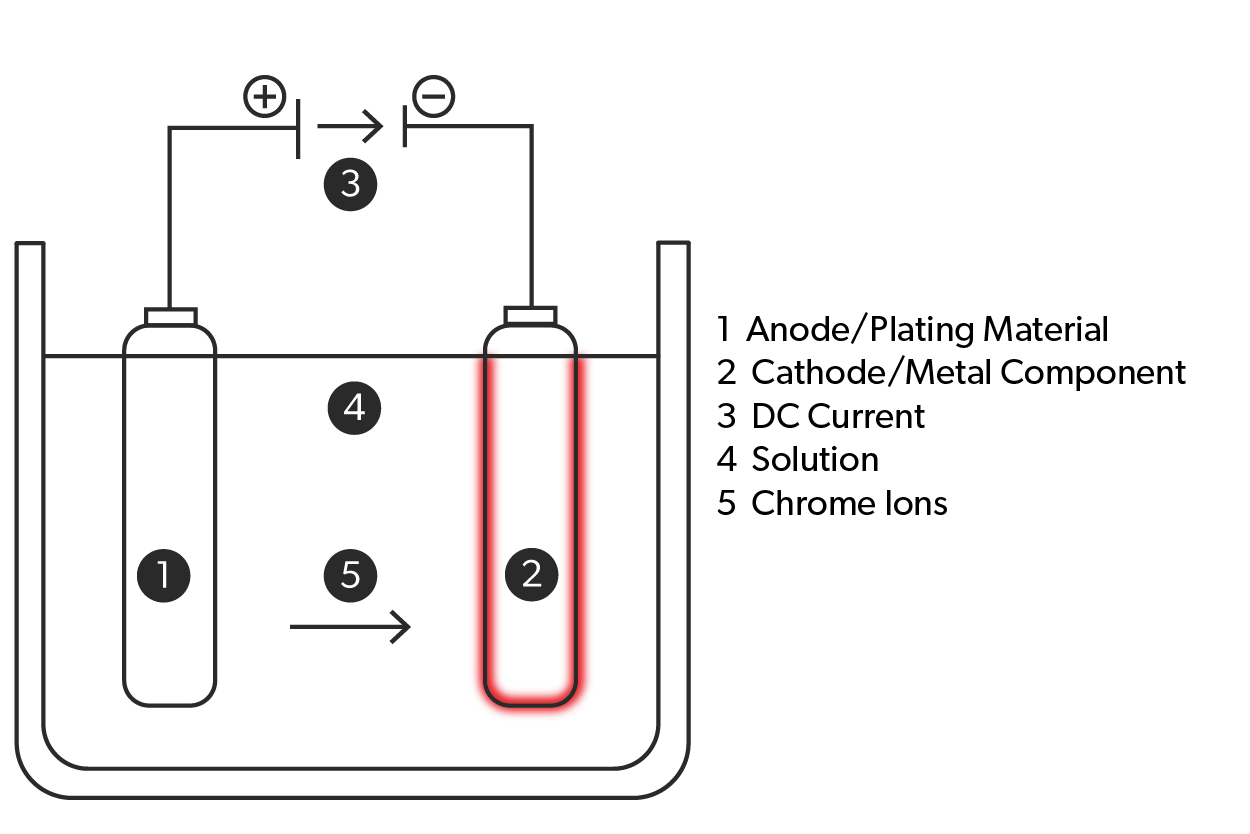

Chrome plating is a popular metal finishing process that provides a shiny, durable, and corrosion-resistant surface. The steps involved in chrome plating are as follows:

1. The metal surface that needs to be plated must undergo thorough cleaning and degreasing to eliminate contaminants and impurities, typically achieved through chemical baths and mechanical processes.

2. Activating the clean surface by applying an acid-based solution to create a receptive surface for chrome plating.

3. An electric current is used to submerge the metal part in a chrome plating solution, causing the chrome ions to deposit onto the surface and form a thin, uniform chrome layer.

4. Rinsing the surface during the plating process, the part is thoroughly rinsed to remove any residual plating solution and then dried to prevent water spots or corrosion.

5. The plated part undergoes inspection for thickness, appearance, and adherence to the chrome layer, with any necessary adjustments or touch-ups made to ensure the final product meets the desired specifications.

6. Depending on the application, the chrome-plated part may undergo additional finishing steps, such as polishing or lacquering, to enhance its appearance and durability.

Chrome plating offers a stunning, mirror-like finish that can elevate the aesthetic of any project. It provides exceptional corrosion resistance, making it ideal for durability and longevity applications. The chrome plating process creates an ultra-smooth surface that is easy to clean and maintain. With its superior hardness, chrome plating can protect underlying materials from wear and tear. Whether you’re looking to enhance the visual appeal or improve the functionality of your project, chrome plating is a versatile and high-performance solution to consider.

AS9100D | ISO 9001 | ITAR Registered

Casting & Molding

Added Value

Connect with us: