A significant contributing manufacturing method is sheet metal fabrication in automotive design. The automotive industry is known for its focus on innovation, precision, and efficiency. A key part of this industry is sheet metal fabrication, which is essential in making strong, lightweight, and well-designed vehicle parts. This process is necessary for creating everything from car body panels to internal structures, contributing to modern vehicles’ safety, look, and performance.

In this blog, we will explore the importance of sheet metal fabrication in the automotive industry, its uses, and how it affects vehicle design and manufacturing.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a vital manufacturing process that changes flat metal sheets into different shapes and structures. This process involves several steps, including cutting, bending, forming, and assembling. These steps create automotive, aerospace, construction, and appliance parts. Manufacturers choose materials such as aluminum, stainless steel, and certain alloys based on their strength, flexibility, lightweight, and resistance to corrosion and heat.

Here are the main techniques in sheet metal fabrication:

Cutting

Standard sheet metal cutting methods include laser, plasma, and waterjet cutting.

Laser cutting uses an intense beam to make precise cuts, allowing for detailed designs and little waste. Plasma cutting uses a quick jet of hot gas to cut through thicker materials. Waterjet cutting relies on a high-pressure water stream mixed with abrasive particles to create clean cuts without damaging the material.

Bending

Bending metal sheets is essential for creating angles and curves. This process uses tools like press brakes and rolling machines. Press brakes push hard on the metal to make bends while rolling machines shape the metal into cylinders. It is essential to bend accurately because this affects how the pieces fit together in the final product.

Welding and Assembly

Welding is a way to join metal parts together using heat and sometimes pressure. The most common methods are MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas), and spot welding. After welding, you can use other methods, like riveting or adhesives, to strengthen the assembly. This step connects all the parts to create a complete and functional product.

Applications of Sheet Metal Fabrication in Automotive Design

Sheet metal fabrication is essential in the automotive industry because it affects the look and performance of vehicles. Here are the primary uses of sheet metal in cars:

Exterior Body Panels

The outer parts of a car, like doors, hoods, roofs, and fenders, are usually made from sheet metal. These panels are lightweight but strong enough to handle impacts and weather.

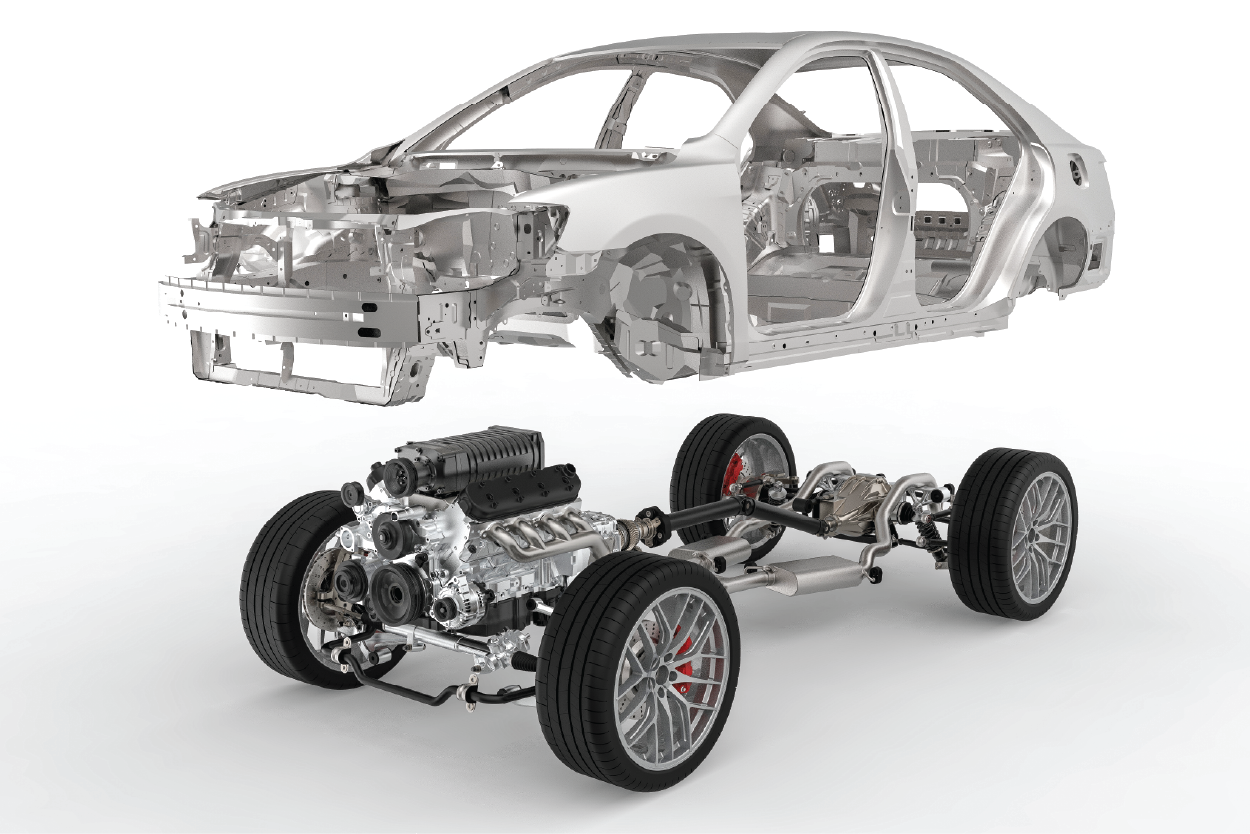

Chassis and Frame

The car’s frame gives it strength and supports the vehicle’s and passengers’ weight. Sheet metal helps make the frame strong and light, which improves safety and fuel efficiency.

Engine and Transmission Parts

Sheet metal is used to make precise parts for the engine, such as brackets, shields, covers, and gearbox components. The engine’s function depends on these parts’ precision.

Interior Components

Sheet metal also makes interior parts like dashboard mounts, seat frames, and supports for safety features like airbags and seat belts.

Exhaust Systems

Car exhaust systems use sheet metal for pipes, mufflers, and catalytic converters. These parts need to resist heat and corrosion to function correctly.

Why Sheet Metal Fabrication is Crucial for the Automotive Industry

Sheet metal fabrication is crucial for vehicle manufacturing. It affects costs, safety, and sustainability. Here’s why it matters:

Lightweight Design for Better Fuel Efficiency

Automotive manufacturers are focusing on making vehicles lighter to reduce emissions. Using materials like aluminum and high-strength steel, for which thin but strong sheet metal parts, helps improve fuel efficiency.

Safety and Strength

Vehicles need to meet strict safety standards to protect passengers. Fabricated sheet metal provides the necessary strength to absorb impacts during accidents and keeps the vehicle’s structure intact. The role of sheet metal fabrication in meeting these safety standards is of utmost importance to automotive industry professionals, as it directly impacts the design and manufacturing processes.

Flexible Design Options

With their sleek designs and complex shapes, today’s vehicles owe much to sheet metal fabrication. This process allows engineers to create detailed designs, helping manufacturers build visually appealing and aerodynamic cars. This aspect of sheet metal fabrication will surely excite automotive enthusiasts about the future of vehicle design.

Durability and Resistance to Corrosion

Fabricated sheet metal often gets a coating to resist damage from harsh conditions, including extreme temperatures, moisture, and road chemicals. This treatment helps parts last longer and reduces maintenance costs.

Adapting for Electric Vehicles (EVs)

As the market moves toward electric vehicles, sheet metal fabrication is changing to meet the specific needs for parts like battery enclosures and lightweight chassis designs.

Technological Advancements in Sheet Metal Fabrication

The automotive industry has dramatically improved thanks to new technologies in sheet metal fabrication. Here are some recent changes that are making a difference:

Automation and Robotics

Manufacturers now use automated machines and robotic arms to improve precision, reduce mistakes, and speed up production. These tools and other jigs and fixtures use sheet metal, machined, and 3D-printed components in their construction.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

These tools help engineers create detailed 3D models of parts. Ensuring accuracy allows simulations to test how parts will hold up before production.

Laser Cutting and Waterjet Cutting

Laser and waterjet cutting technologies are essential in the automotive industry for cutting sheet metal with high precision. These methods use focused laser beams and high-pressure water jets to create detailed designs with clean edges. They reduce material waste and ensure a high-quality finish.

These technologies can accurately cut various metals, including aluminum, steel, and titanium. This accuracy is essential for making parts that meet strict automotive design and safety standards. They also allow for fast production while keeping accuracy for complex assemblies.

Sustainable Materials

Manufacturers are using recycled metals and lightweight materials to lessen their environmental impact. This change reduces energy consumption, waste, and greenhouse gas emissions, promoting sustainability and meeting consumer demand for eco-friendly products.

The Future of Sheet Metal Fabrication in the Automotive Industry

As the automotive industry changes, better sheet metal fabrication will be needed. Here are some key trends to watch:

Use of Lightweight Materials

More electric vehicles mean more significant use of light metals like aluminum and magnesium alloys.

AI and Machine Learning

AI systems will improve quality control, streamline production, and help predict maintenance needs for fabrication machines.

Conclusion

Sheet metal fabrication is essential in the automotive industry. It provides the basic structure for making reliable, efficient, attractive vehicles. This process is flexible, cost-effective, and works well with new technologies, making it key in car manufacturing.

As the industry shifts to electric vehicles and sustainable practices, sheet metal fabrication will still be essential for shaping future cars. Whether you drive a sports car or an SUV, remember that the smooth curves and shapes come from skilled sheet metal fabrication—a reflection of modern engineering skills.

FAQs

Sheet metal fabrication is crucial in automotive manufacturing, enabling the creation of complex, durable, and lightweight components essential for vehicle performance and safety.

The most common sheet metal fabrication materials used in the automotive industry are steel, aluminum, and stainless steel.