Sheet Metal Prototyping Services at Prototek

Prototek’s sheet metal prototyping services offer:

- Facilities Throughout the USA

- Bending & Forming, Laser Cutting, Waterjet Cutting, Welding, and Assembly

- Fabricated Metals, Plastics, and Other Materials

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- 100+ Materials

- 40+ Surface Finishes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

The Importance of Sheet Metal Prototyping in Modern Manufacturing

In today’s fast-paced manufacturing world, sheet metal prototyping is a key process for companies that want to innovate and improve their product designs. This method lets engineers and designers quickly create physical models of their ideas. They can test these models and validate their concepts before starting full-scale production.

What is Sheet Metal Prototyping?

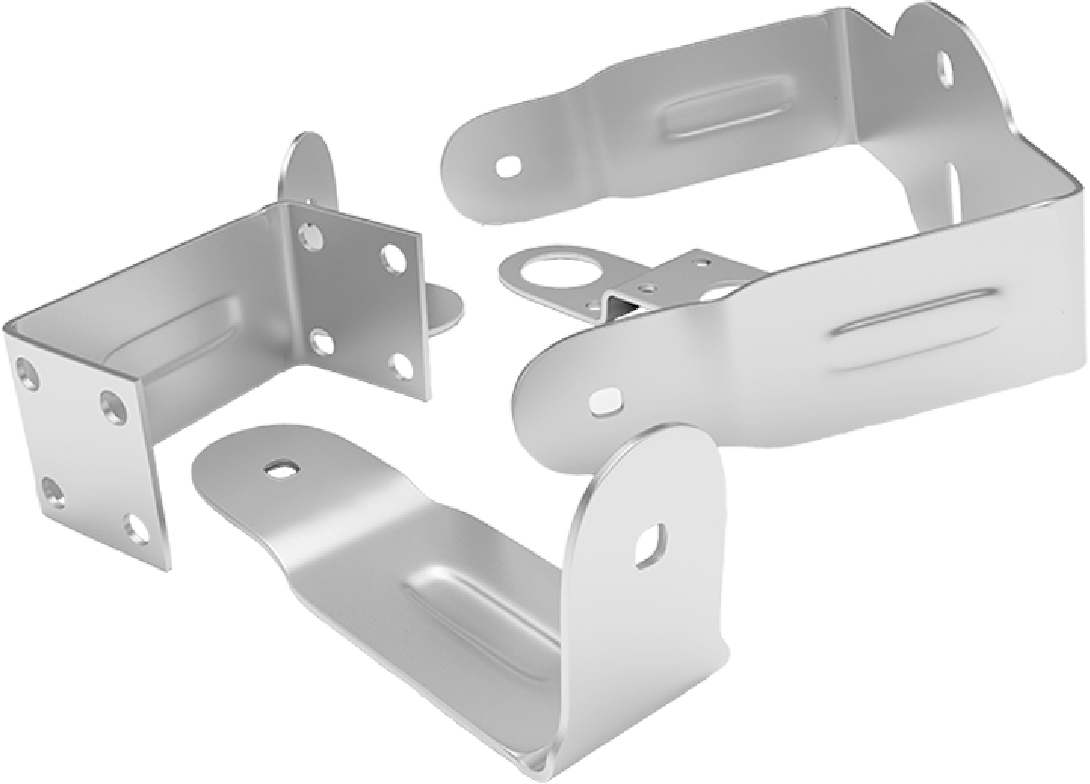

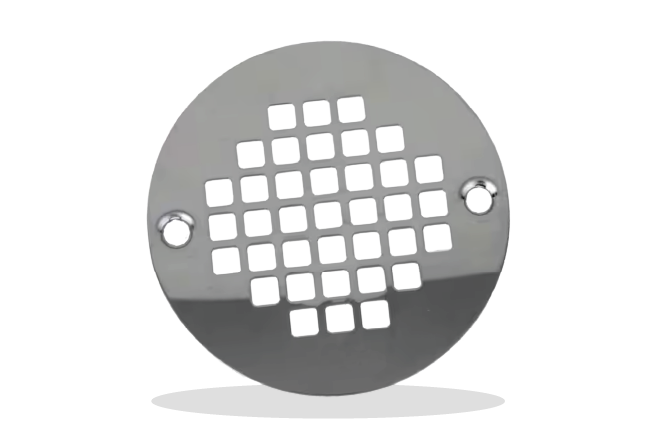

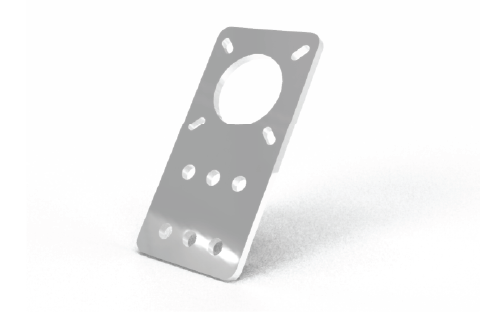

Sheet metal prototyping involves creating a prototype using thin sheets of metal, which can be cut, bent, and assembled into various shapes and structures. Common materials used in this process include aluminum, steel, and brass. The prototyping phase allows for evaluating form, fit, and function, ensuring that the final product meets design specifications and user requirements.

Why is Sheet Metal Prototyping Important?

- Speed to Market: In industries where timing matters, metal prototyping helps companies quickly turn ideas into physical models. This fast process shortens development cycles, enabling businesses to launch products sooner.

- Cost Efficiency: Prototyping lets companies find design flaws early, reducing the risk of expensive changes during production. Fixing issues before mass production also saves on materials and labor costs.

- Design Validation: Physical prototypes allow for real-world testing of designs. Engineers can check how well the product works, how durable it is, and how easy it is to use. Leading to better decisions.

- Enhanced Collaboration: Prototypes act as physical examples of ideas, improving communication among team members and stakeholders. This teamwork ensures that everyone understands the project vision.

The Sheet Metal Prototyping Process

The process of creating sheet metal prototypes involves several essential steps:

- Concept Development: Designers start by brainstorming and sketching ideas. They then work with engineers to form a clear vision for the prototype.

- CAD Modeling: Our customers create a Computer-Aided Design (CAD) model after finalizing the concept. This digital model includes exact measurements and details necessary for fabrication.

- Fabrication: Use advanced manufacturing techniques to turn the CAD model into a physical prototype. This step may use laser cutting, CNC machining, bending, and welding.

- Assembly: We assemble all components into the final prototype after manufacturing them. This stage may also involve surface finishing or coating.

- Testing and Evaluation: Test the prototype to check its performance, functionality, and compliance with standards. Feedback from testing can help make improvements.

- Iteration: Adjust the prototype based on the test results. This process may involve several revisions until the final design is approved.

Prototek's Sheet Metal Prototyping Services

Bending & Forming

OEM:

Amada and Birmingham

Lead Time:

1 -15 Days

Max Dimensions:

61 x 0.1345 in (10 Ga.)

Roll Length & Diameter: 4-3/4 in

(capacity based on Mild Steel)

Pinch Adjustment: Standard

Laser Cutting

OEM:

Amada, Beam Dynamics, Epilog, IPG

Lead Time:

1 -15 Days

Max Dimensions:

61 x 99 x 11.8 in

Waterjet Cutting

OEM:

Flow

Lead Time:

1 -15 Days

Max Dimensions:

Linear Straightness: ± 0.0021 in

Repeatability: 0.0014 in

Metal Materials for Prototyping and Production

Prototek offers a variety of sheet materials, including aluminum, copper, stainless steel, and titanium. These materials have various properties, and our experts can help clients choose the right one for their prototyping projects.

Aluminum

Aluminum sheet metal is an excellent option for prototyping because it is versatile, durable, and cost-effective. It is lightweight yet strong, allowing quick testing and design changes. Additionally, aluminum resists corrosion, making it a popular choice for many prototyping projects.

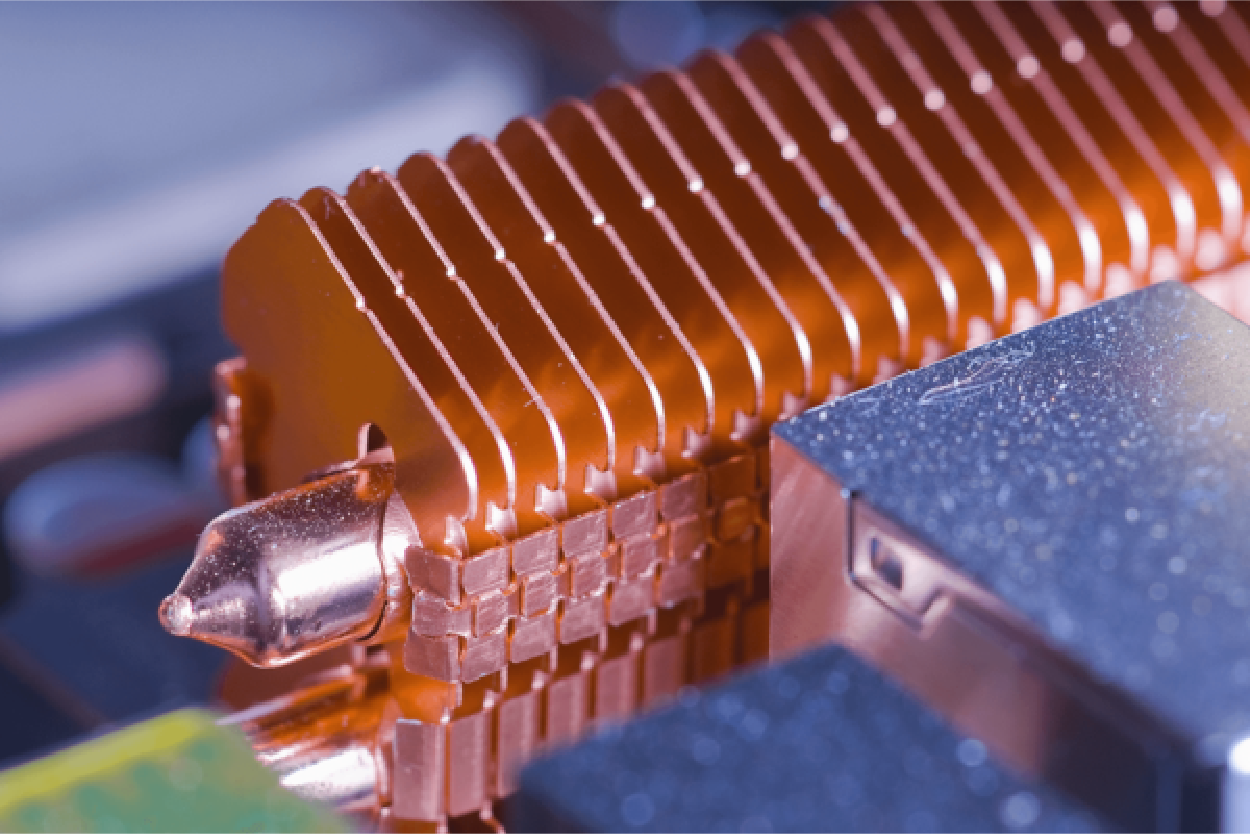

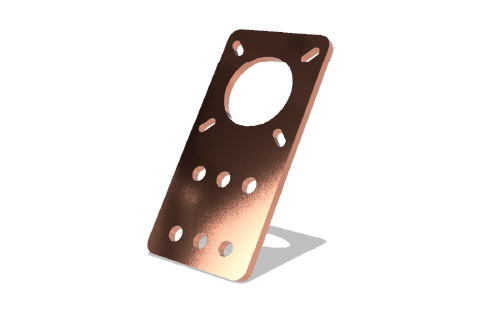

Copper

Copper sheet metal is an excellent option for prototyping because of its special qualities. It conducts electricity and heat well, making it suitable for electronic parts and heat management. Additionally, it resists corrosion and is durable, which makes it a dependable choice for many prototyping tasks.

Stainless Steel

Stainless steel sheet metal is an excellent choice for prototyping because it is durable, resistant to rust, and versatile. Its strength allows it to hold up during testing. Additionally, stainless steel looks good and is easy to shape and machine, making it popular for showing design ideas.

Titanium

Titanium sheet metal is an excellent choice for prototyping because it is strong, light, and corrosion-resistant. It can also handle high temperatures, making it ideal for building durable, high-performance prototypes in many industries.

Innovation to scale with Prototek!

Bridging the Gap from Sheet Metal Prototypes to Production Parts.

Prototek Digital Manufacturing is a trusted service provider that helps you turn your sheet metal prototypes into production-ready parts. We use advanced technology and a skilled team to complete your projects accurately and quickly. Our priority is to deliver high-quality products and services, ensuring your satisfaction. Whether you need rapid prototyping or traditional manufacturing methods, we have the knowledge and resources to do it right. Choose Prototek Digital Manufacturing for your sheet metal fabrication needs and enjoy top-quality, reliable performance.

Learn More About Prototek's Sheet Metal Fabrication Services

Through our resources, you can discover the complexities of Sheet Metal Fabrication and gain insights into creating top-notch designs specifically tailored for this cutting-edge technology.

Drone Manufacturing: A Guide From Components to Production

Learn about the key parts that make drones fly and the new materials that improve their performance. See how drones change aerial photography, farming, delivery...

Rapid Prototyping: Bridging Ideas and Reality

In today's fast-paced world, rapid prototyping makes turning innovative ideas into products easier than ever. By utilizing advanced technologies like 3D printing and machining, designers...

What Is Kovar and Why Is It Important?

Kovar is a significant nickel-iron alloy widely used in electronics, aerospace, and medical devices. Developed in the 1920s, Kovar possesses unique properties, such as expanding...

Sheet Metal FAQs

Sheet metal prototyping entails creating physical models or samples using thin, flat pieces of metal. This approach allows for rapid, cost-effective testing and validation of product designs before full-scale manufacturing. Additionally, it enables quick iterations and ensures that the final product meets all functional and aesthetic requirements.

At Prototek, we provide various finishing options for your custom sheet metal prototypes, including powder coating, plating, anodizing, and painting. Our expert team can also assist you in selecting the perfect finish to meet your specific requirements and enhance the appearance and durability of your parts.

Prototek provides precision sheet metal prototyping services focusing on quality, speed, and flexibility. Our advanced equipment and skilled team create your designs with great accuracy and detail. We offer rapid prototyping and low-volume production, providing reliable and cost-effective solutions for your project needs. Trust Prototek to help turn your ideas into high-quality metal parts.

Rapid turnaround and high-quality parts for your prototype projects.

Sheet metal prototypes have limited design flexibility and require specialized equipment.

If you’ve got questions about your parts design for manufacturability, please don’t hesitate to email one of our engineers at quotes@prototek.com!