Casting Services:

Welded Parts

Prototek’s welding services offer the following:

- Reliable & Efficient

- Cost Effective

- Allow for Custom Prototypes and End-Use Parts

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

- Instant and Engineer-Assisted Quotes

- Certifications: ISO 9001:2015, AS9100D, and ITAR

-

Instant and

Engineer-Assisted

Quotes - 100+ Materials

-

40+ Surface

Finishes -

Certifications:

ISO 9001:2015,

AS9100D, and ITAR -

In-House Services: 3D Printing,

CNC Machining, Urethane Casting,

and Sheet Metal Fabrication

Our Process is Simple.

Upload a CAD file and request a quote.

Our team will start production.

Once complete, it passes through quality control.

Lastly, our team ships the part(s) to you.

What is Welding?

Welding is a fabrication process that utilizes heat and pressure to join materials, such as metals or thermoplastics. The primary objective is to create a strong and permanent bond between the materials. Welding is indispensable in various industries, including construction, automotive, shipbuilding, and aerospace. Different techniques, such as MIG, TIG, spot welding, and grinding, are employed depending on the type of material and its intended application. It requires skilled training and expertise to produce durable and high-quality joints. Moreover, welding plays a critical role in manufacturing and maintenance operations. With the advancement of automation, the process is becoming more precise, faster, and safer.

How does Welding work?

Welding is joining two or more pieces of metal by applying heat or pressure. It is crucial in manufacturing, construction, and machinery repair.

There are various welding techniques, each with unique features, advantages, and applications.

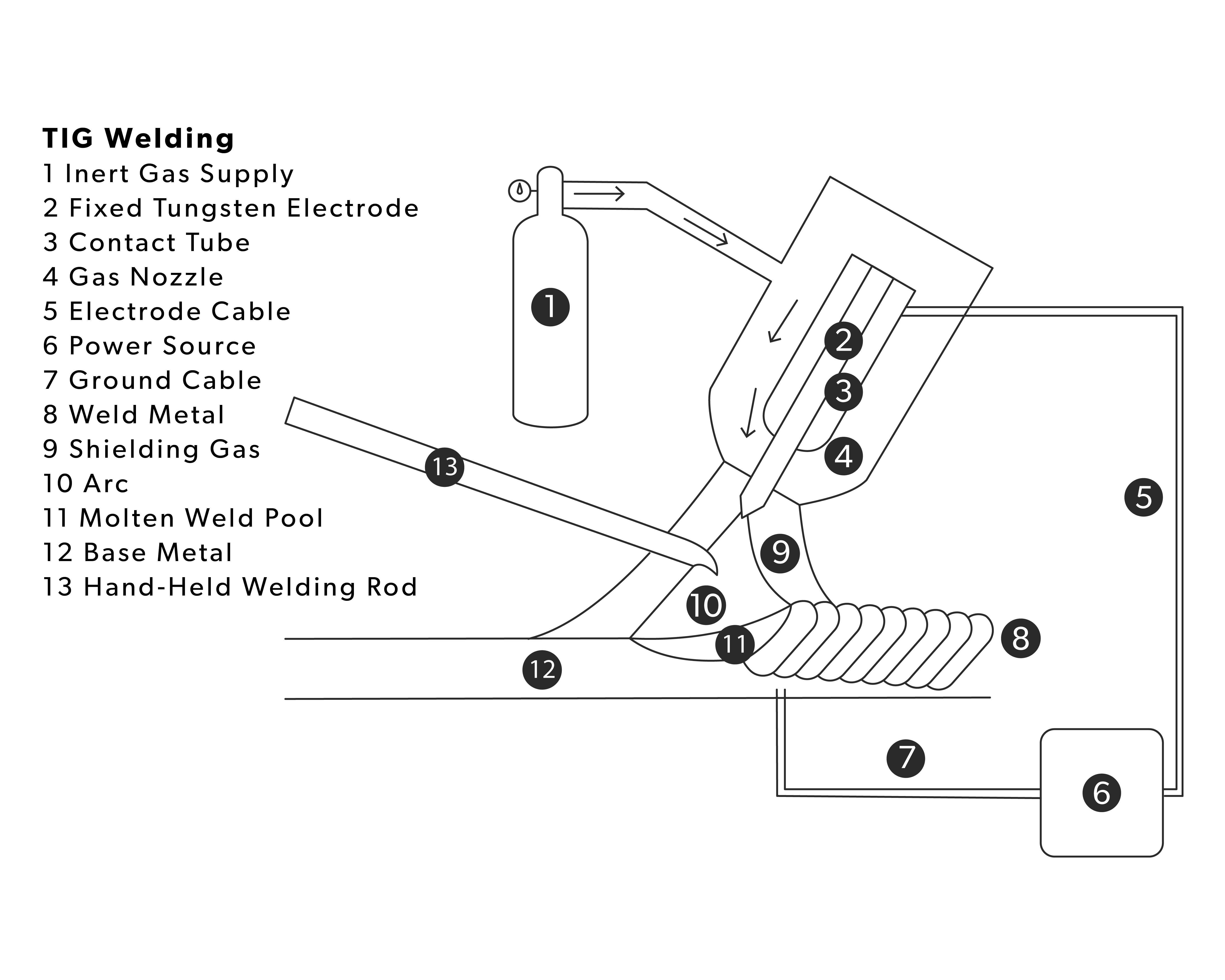

For example, TIG welding uses a tungsten electrode to create an electric arc between the metal and the electrode. The heat from the arc melts the metal, while a shielding gas protects the weld from contamination. Additionally, a filler rod is used to join the metal pieces. TIG welding is suitable for thin materials and produces high-quality welds.

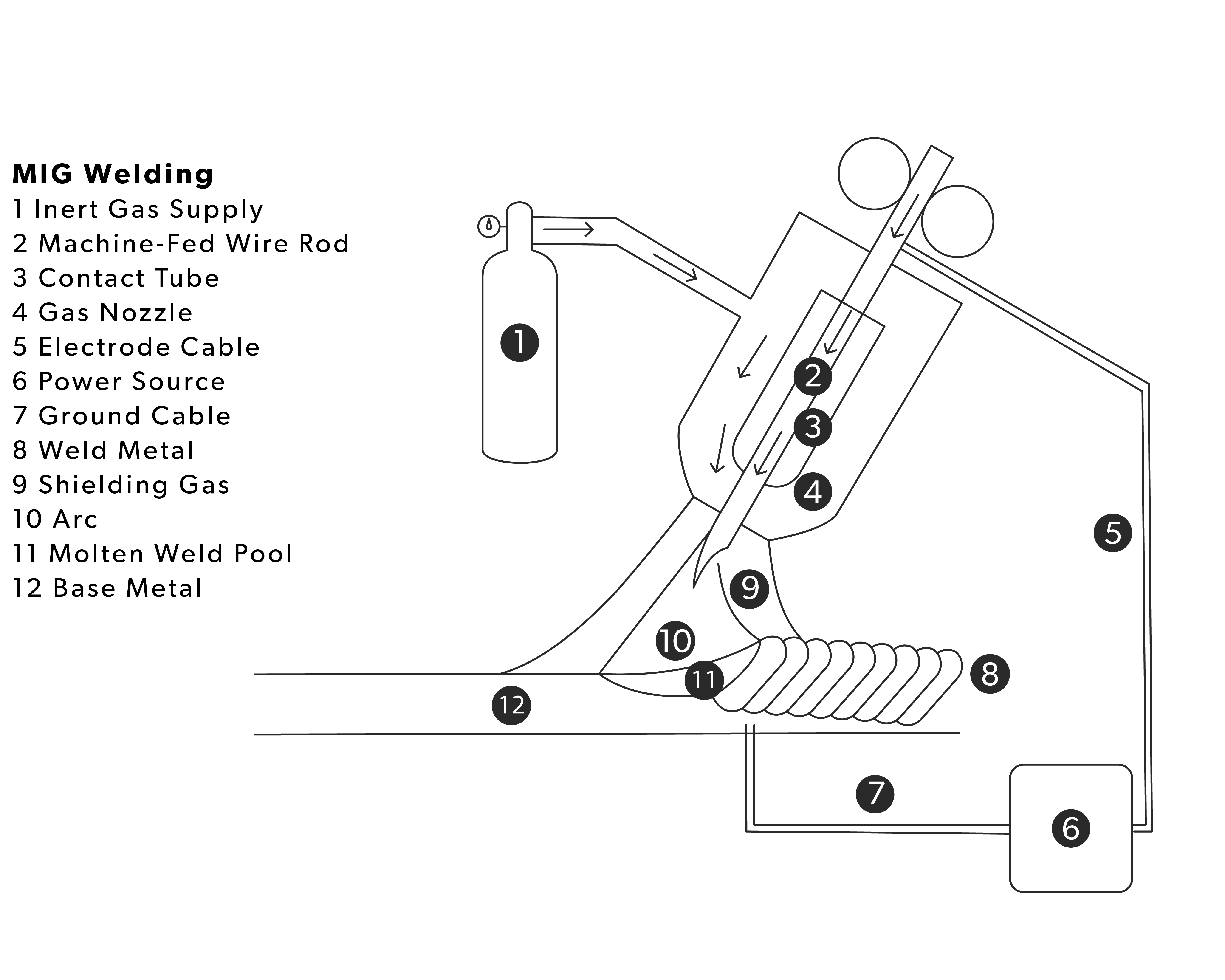

On the other hand, MIG welding uses a wire electrode to create an arc between the metal and the electrode. As a result, the wire electrode melts through the welding gun, and the molten metal is deposited onto the joint to create a strong bond. MIG welding is ideal for thicker materials and can be used on various metals, including aluminum, stainless steel, and mild steel.

Arc welding employs an electric current to pass through an electrode to produce intense heat. Consequently, the heat softens the metal, creating a pool of molten metal that cools and solidifies to form a strong joint. There are several types of arc welding, including shielded metal arc (SMAW), gas tungsten arc (GTAW), and gas metal arc (GMAW), each with its advantages and limitations.

Spot welding is a type of resistance welding that involves pressing two metal pieces together and passing an electric current through them, melting the metal at the point of contact. This method is commonly used in the automotive industry to join sheet metal components.

Laser welding uses a highly concentrated light beam to fuse metal pieces precisely. Industries such as aerospace and automotive rely on this method for high-quality and efficient welding. Laser welding offers advantages such as faster welding times, working with complex shapes, and minimal distortion. As a continuously evolving technology, Prototek stays up-to-date with the latest advancements in laser welding.

Weld grinding involves smoothing and shaping the welded joint with a grinding wheel. This essential step removes excess metal and shapes the weld to the desired finish. Depending on the size and complexity of the weld, grinding can be done manually or using automated equipment.

Design considerations for Welding.

Welding is a crucial process that requires meticulous design considerations to ensure success. The design should take into account various factors such as material type, thickness, joint configuration, and weld quality requirements. One crucial consideration is the selection of the welding process, which depends on factors such as accessibility, position, joint type, and material thickness. Furthermore, the joint design should also consider the stresses and loads the joint will face during its service life. Additionally, a critical design consideration is the selection of suitable filler materials, which should match or exceed the base material’s strength and corrosion resistance. Moreover, our operators also ensure proper equipment maintenance and follow all safety guidelines to achieve the desired results.

Butt Joint

Two pieces of metal are joined at their ends, creating a strong and seamless connection.

Tee Joint

Two materials (usually metal) intersect at a 90-degree angle.

Edge Joint

Two pieces of metal are joined together at their edges.

Corner Joint

Two pieces of metal meet at a 90-degree angle that forms an “L” or corner.

Lap Joint

Two overlapping pieces of metal are welded together to form a strong connection.

Why choose Prototek for your next project?

Prototek is a highly specialized metal fabrication company with years of experience in the industry. We proudly offer advanced technology and high-quality materials to provide fast, precise, and reliable welding services that meet your specifications. Our services include CNC machining, laser cutting, and sheet metal fabrication, all performed with the highest level of skill and precision. We work closely with clients to produce prototypes and custom metal parts quickly and cost-effectively, ensuring we meet your specific requirements and exceed your expectations. At Prototek, we are committed to delivering high-quality work completed on time and within budget. We understand the importance of timely delivery and strive to ensure that our clients receive their orders promptly, no matter how complex or challenging the project. We take pride in delivering complex projects on time and within budget. Our team of skilled professionals is dedicated to providing the best possible service and artistry, and we always go the extra mile to ensure that our clients are delighted with our work. If you are looking for a reliable and experienced metal fabrication company that can deliver the highest quality work, look no further than Prototek. We are your go-to source for all your metal fabrication needs!