Wire EDM, a precise and versatile manufacturing process, has a rich history that dates back to the 1960s. Over the years, it has evolved into an advanced technology now a cornerstone of modern industrial production. This blog post will explore the key benefits of wire-cutting EDM, its applications across various industries, and how it can help businesses achieve their manufacturing goals.

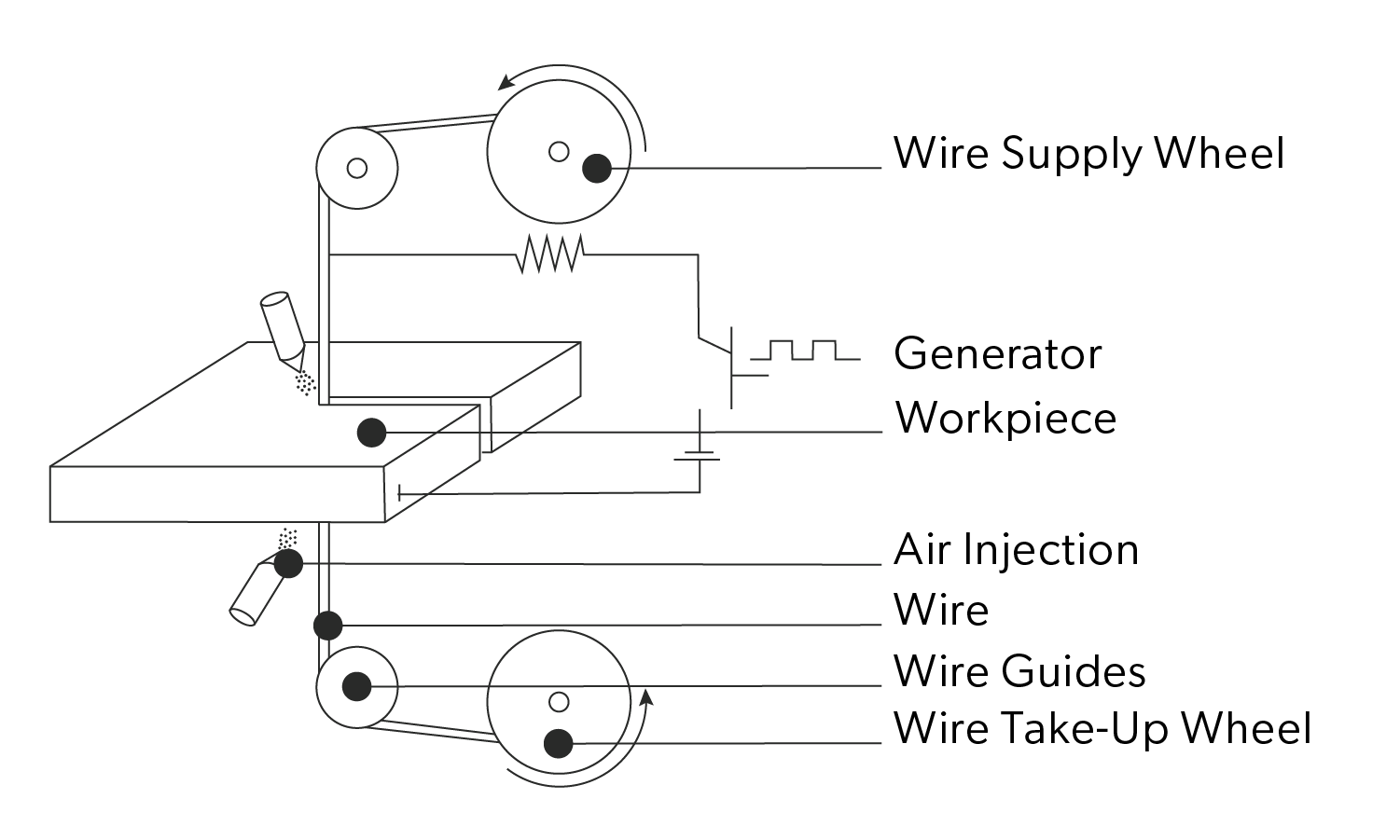

How does wire-cutting EDM work?

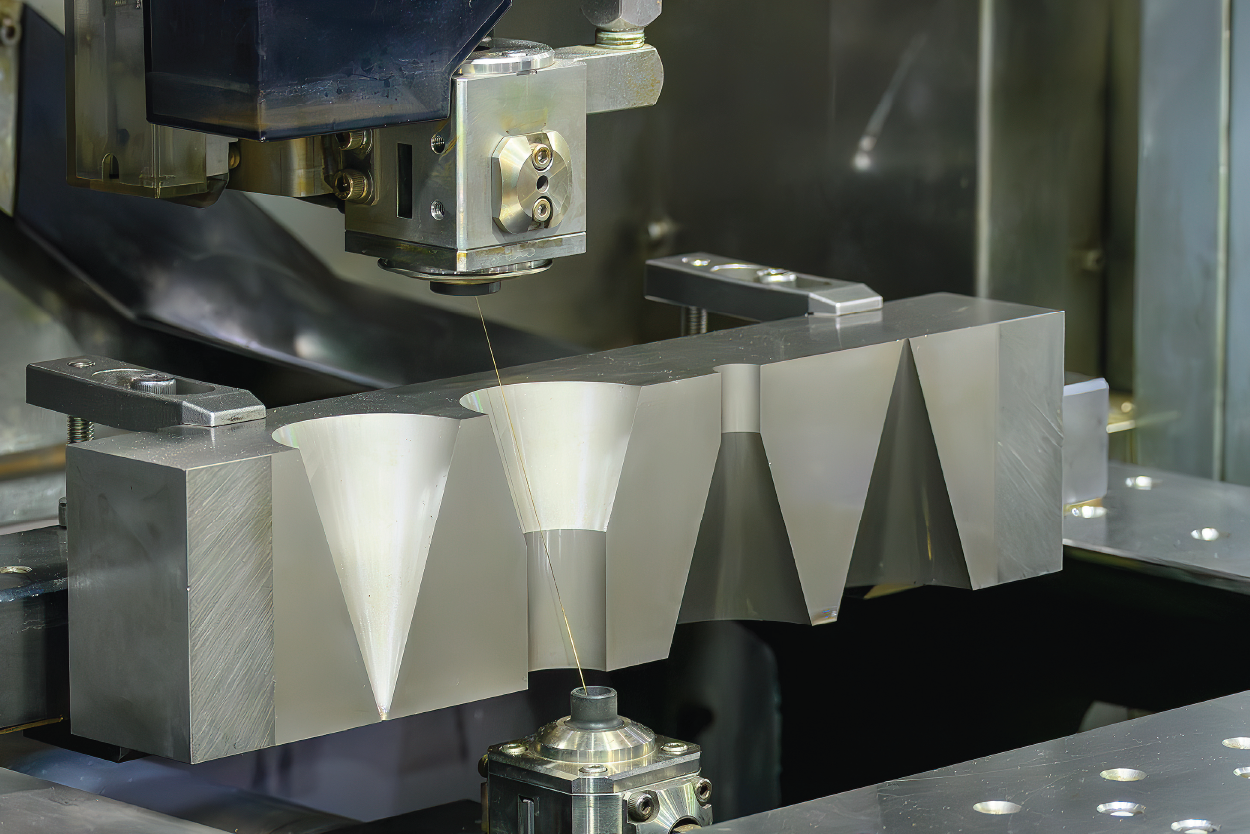

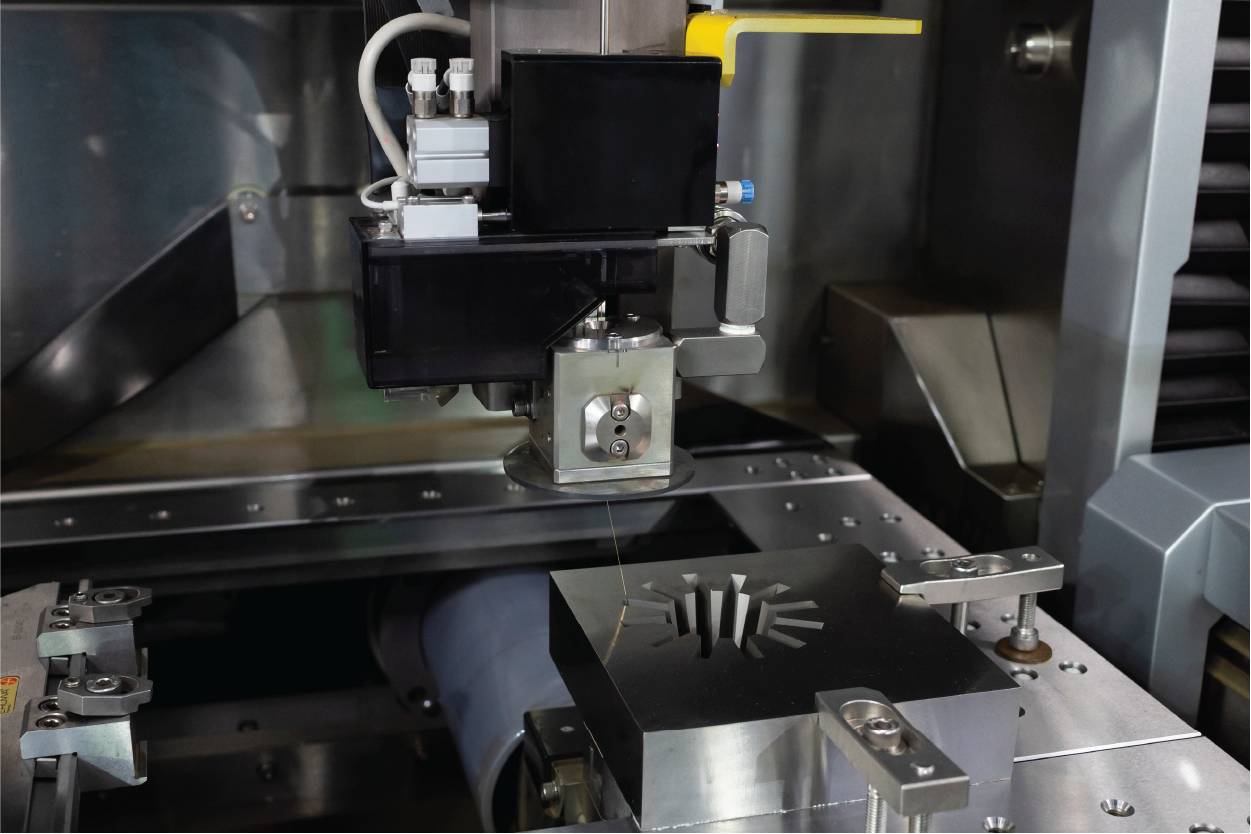

Wire Electrical Discharge Machining (Wire EDM) is a precise and versatile manufacturing process that utilizes a thin, continuously moving wire electrode to cut intricate shapes and geometries into conductive materials. Submerging the workpiece in a dielectric fluid is the next step, and a controlled electrical discharge is generated between the wire and the workpiece. This non-contact process erodes the material and creates the expected shape, allowing for intricate cuts and tight tolerances. This unique feature makes it an ideal solution for producing parts with complex features, tight clearances, and delicate components.

What are the benefits of wire-cutting EDM?

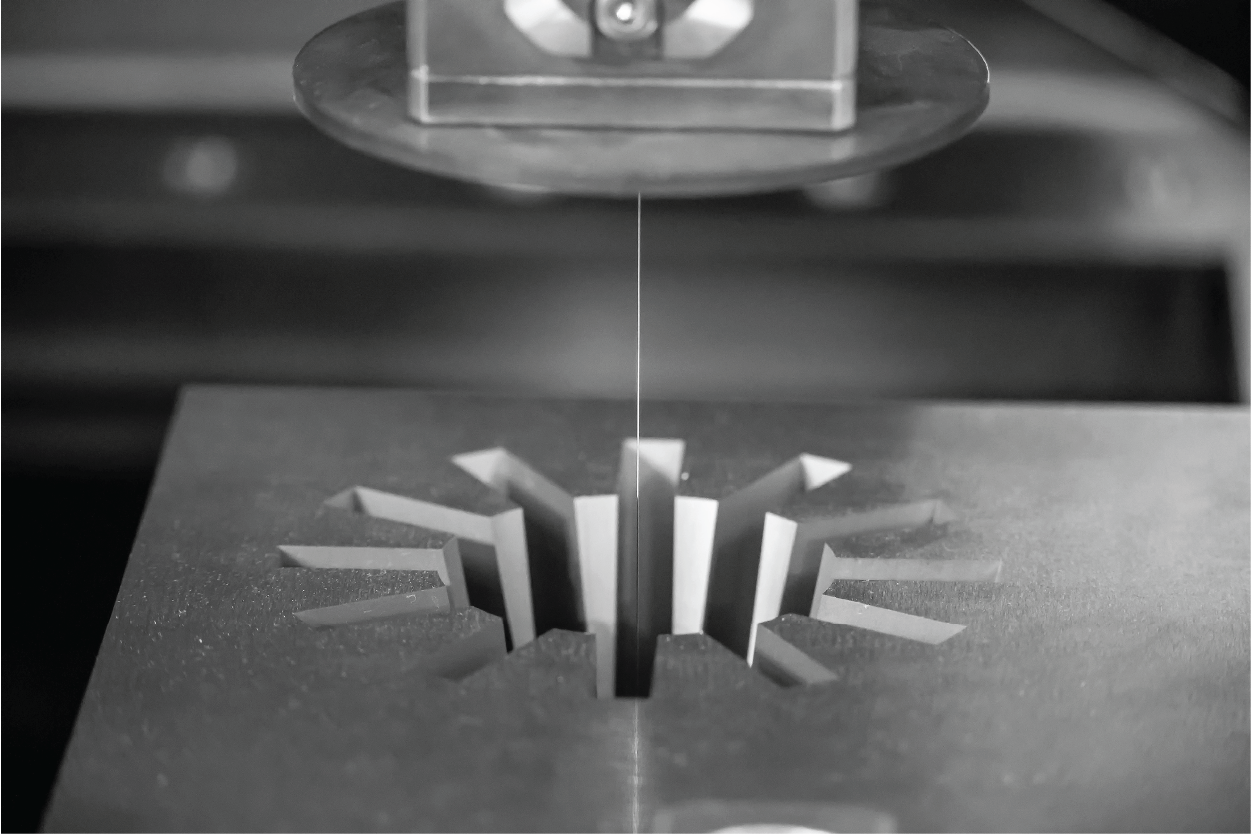

One of the primary advantages of wire-cutting EDM is its ability to create complex, intricate parts with unparalleled accuracy and repeatability. Additionally, the non-contact nature of the process allows for the fabrication of components with tight tolerances, delicate features, and intricate geometries, which would be extremely difficult or impossible to achieve through traditional machining methods.

Furthermore, wire EDM offers a critical benefit in its versatility. The technology can process various conductive materials, including metals, alloys, and ceramics. This wide range of applications, from aerospace and automotive to medical and electronics, makes wire EDM an inspiring solution for producing multiple components across numerous industries.

Moreover, wire-cutting EDM is precise, highly efficient, and cost-effective. Eliminating the need for physical tooling reduces setup times and material waste, leading to significant cost savings for our clients. The automated nature of wire EDM further enhances productivity and reduces labor costs, providing reassurance about its efficiency and cost-effectiveness.

What are the applications for wire-cutting EDM?

Wire-cutting Electrical Discharge Machining (wire EDM) is a highly versatile manufacturing process with various industrial applications. This process is particularly well-suited for applications that require precise tolerances and intricate details. Some of the key applications for wire EDM include:

- Cutting intricate parts and components for the aerospace, automotive, and medical device industries.

- Producing complex mold and die components with tight tolerances and fine surface finishes.

- Machining hard, brittle, or heat-sensitive materials that are difficult to machine using traditional methods.

- Cutting slots, cavities, and other features into tools, punches, and extrusion dies.

- Fabricating precision parts, tools, and components for the electronics and semiconductor sectors.

Moreover, wire EDM’s capability to cut complex 2D and 3D shapes with high accuracy and repeatability makes it an invaluable manufacturing process across various industries. This versatility and precision make wire-cutting EDM the ideal solution for producing intricate components in multiple sectors.

In addition, at Prototek, we leverage our expertise in wire EDM to deliver high-quality parts and components for our customers. Furthermore, our commitment to excellence and cutting-edge technology ensures we meet and exceed our clients’ expectations.

Why choose this manufacturing method for your project?

Wire EDM is an exact and versatile manufacturing process that can significantly benefit your project. It can create complex geometries and tight tolerances, making it an excellent choice for various applications. This technology offers unparalleled accuracy, repeatability, and surface finish, making it an ideal solution for producing intricate parts and components. By leveraging the capabilities of wire EDM, you can unlock new design possibilities, improve product performance, and enhance the overall quality of your project.

FAQs

Wire-cutting EDM is widely used in the aerospace, automotive, and medical industries.