Brass is an alloy mainly containing copper and zinc. It has been a common choice in various industries for centuries because of its strength, resistance to rust, and attractive appearance. These qualities make brass a common choice for both decorative and practical purposes. This article will explain the history, properties, and uses of brass.

What is brass?

Brass is a strong alloy mainly of copper and zinc. It usually contains about 60-70% copper and 30-40% zinc, which gives brass its golden color and useful properties.

Brass is resistant to corrosion, which means it can withstand tough environments without breaking down. It is also easy to work with, so creating different items from brass is simple.

Brass is used for many purposes, such as plumbing fittings, musical instruments, decorative items, and hardware. Its strength and flexibility make it a popular choice in both industry and art, ensuring its use in many areas.

What is the history of brass, and how is it made?

Brass has a long history, stretching back thousands of years. People have used it for many purposes, from decorations to tools. This connection to our past shows the creativity of our ancestors.

Brass production began in the Bronze Age when metalworkers learned that mixing copper and zinc created a stronger, more durable material than pure copper. This discovery changed how people made tools, weapons, armor, household items, and religious objects.

Brass manufacturing methods have developed significantly over time. Today, companies use techniques like casting, rolling, and extrusion to create high-quality brass. They can adjust the mix of copper and zinc according to specific needs for different projects, ensuring that brass performs well in any application.

Prototek Digital Manufacturing offers services like CNC machining and sheet metal fabrication. Our skilled team works closely with clients to produce components that meet high-quality and performance standards. This expertise gives our clients confidence in our brass manufacturing services.

Whether you need brass parts for a restoration project or modern industrial use, Prototek Digital Manufacturing has the skills and resources to help you succeed.

Mechanical Properties of Brass

Brass is a versatile metal alloy made mainly of copper and zinc. Manufacturers often add elements like lead or tin to improve its properties. Here are the main mechanical properties of brass:

High Strength

Brass is strong and can support heavy loads. This property makes it useful in the construction, automotive, and plumbing industries.

Corrosion Resistance

Brass resists corrosion well, which helps it last longer in various environments. Over time, it forms a protective layer, increasing its resistance to rust.

Ductility

Brass can be easily shaped, bent, and formed without breaking. This feature makes it popular for musical instruments, plumbing fixtures, and decorative hardware.

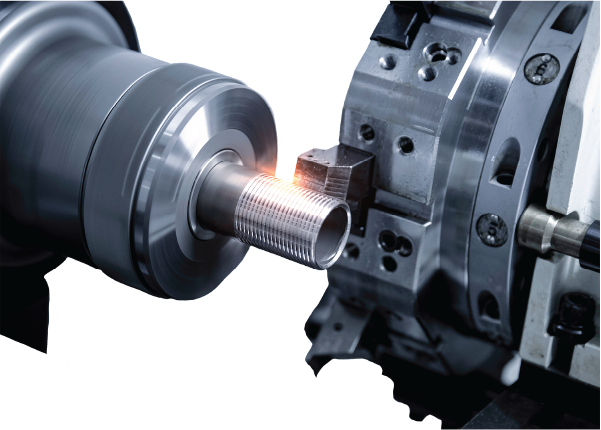

Machinability

Brass is easy to machine, allowing for the production of detailed parts with high precision. This property is essential in fields like electronics and aerospace.

Thermal Conductivity

Brass conducts heat moderately well, making it suitable for heat transfer applications, such as heat exchangers, radiator cores, and plumbing systems.

Understanding brass’s history and properties reveals why it continues to be valuable in various applications today.

What types of brass alloys are popular?

Brass is made from copper and zinc and comes in different grades and alloys, each with its properties and uses. Here are some popular types of brass.

Yellow Brass

Also known as 360 brass or cartridge brass, it contains about 70% copper and 30% zinc. This blend gives yellow brass a bright, golden color, making it easy to machine. People commonly use it for plumbing fittings, hardware, and decorative items.

Red Brass

Red brass, also known as 430 brass, has a higher copper content, usually around 85%, which gives it a reddish color. Red brass is known for its corrosion resistance. It is often used in marine applications and for architectural hardware and decorations.

Leaded Brass

Also called 360 brass, it is yellow brass that includes lead. The lead improves its machineability and allows for tighter manufacturing tolerances. Plumbing fittings, valves, and other precise components often use it.

Aluminum Brass

Otherwise known as 443 brass, it contains 2-3% aluminum. The aluminum improves the alloy’s corrosion resistance and strength, making it ideal for marine applications, heat exchangers, and other parts exposed to harsh conditions.

These examples show the various brass grades and alloys available, each suited for different needs. At Prototek Digital Manufacturing, we can help you select the right material for your project.

Which industries use brass, and what are some of its applications?

Brass is an essential material made from copper and zinc. It resists corrosion, is easy to shape, and looks good, making it applicable across various industries.

Brass has versatile applications, from luxury hotel fixtures to industrial machinery gear. It is vital for the products and structures that support our modern world. Here are some industries that use brass and some of its key applications.

Brass is popular in construction for making durable and attractive plumbing fixtures, door hardware, and architectural elements. Its corrosion resistance makes it suitable for outdoor use.

Brass parts are crucial in transportation industries. Automakers and aerospace engineers use brass because it is strong, resists heat, and can handle stress. Typical applications include engine parts and aircraft fittings.

Brass is vital in electrical and electronic applications due to its conductivity and machinability. It is essential for digital devices, including circuit board contacts and telecommunications cable shielding.

Brass’s versatility makes it essential in many industries. As technology evolves, brass will continue to support innovation across sectors, including construction, automotive, and electronics.

What are the benefits of using this material?

Brass is a flexible material with unique qualities that make it suitable for many applications. Its resistance to corrosion, excellent thermal and electrical conductivity, and attractive appearance make it a favored choice for electrical parts, plumbing fixtures, and decorative designs. Additionally, brass is easy to machine and recyclable, making it an environmentally friendly option.

Why choose this material for your project?

Brass is an excellent choice for your project due to its mix of strength, durability, and aesthetic appeal. It is ideal for applications needing long-lasting performance, and its warm, bright gold hue adds elegance to designs. With our precision manufacturing, we can deliver components that fit your requirements—Trust Prototek Digital Manufacturing to provide the high-quality solutions you need to realize your vision.

CNC Machine Shop Services

Prototek offers state-of-the-art CNC machining services to meet your precise manufacturing needs. Our skilled technicians utilize the latest CNC technology to deliver high-quality components with unparalleled precision and efficiency—Trust Prototek for all your CNC machining requirements.

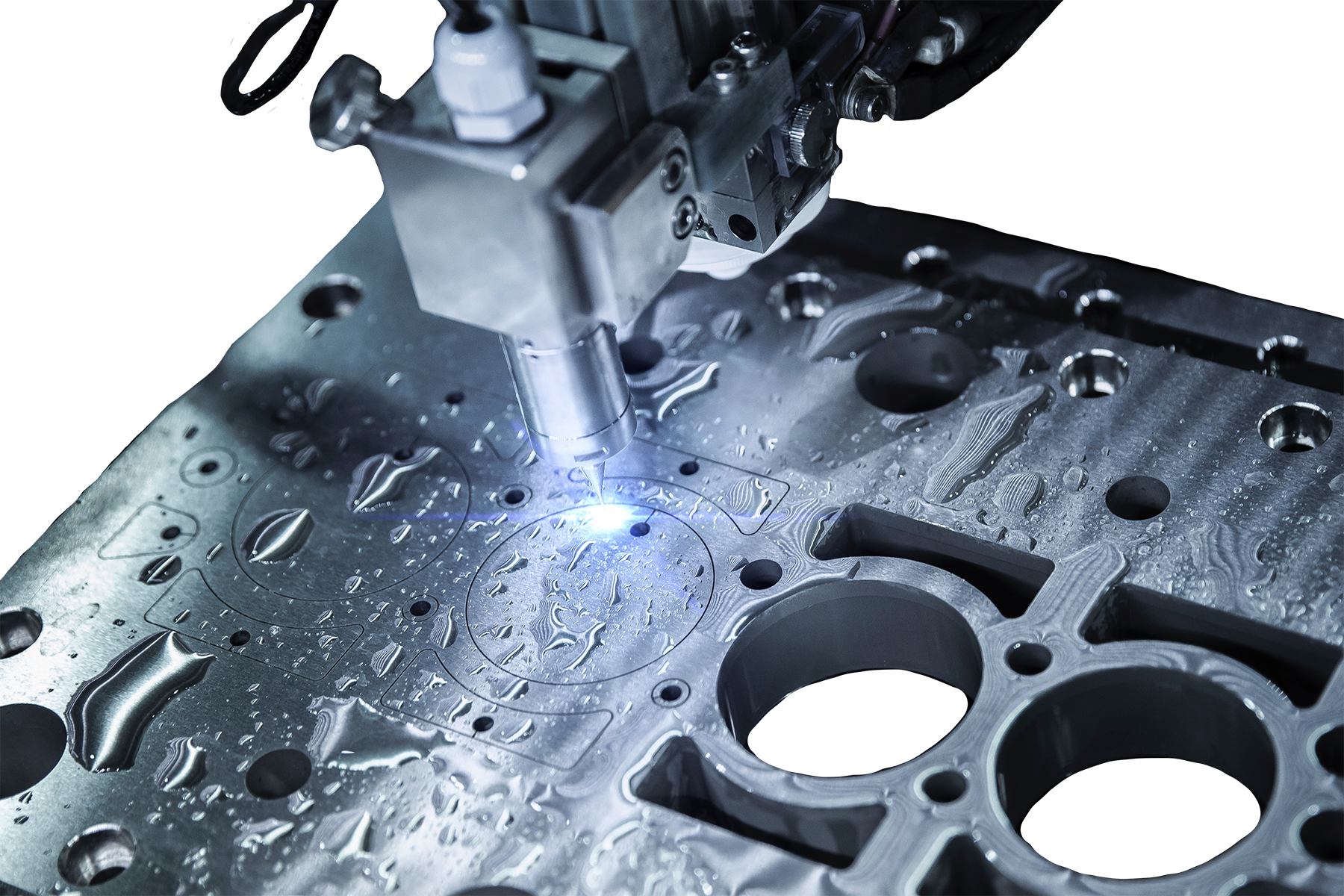

Sheet Metal Fabrication Services

At Prototek, we offer comprehensive sheet metal fabrication services to meet your manufacturing needs. Our skilled team utilizes the latest technology and techniques to deliver high-quality, precision-engineered components. From prototyping to production, trust Prototek to bring your ideas to life.

FAQs

Brass is an alloy mainly made from copper and zinc. It is known for its gold color and is helpful in many industrial and decorative applications.

Brass is not magnetic. It does not contain ferromagnetic materials like iron or steel.

Brass resists corrosion and rust. While it may tarnish over time, proper care can help it retain its shine.

Brass can tarnish due to oxidation over time. However, proper care and cleaning can maintain its shine.

Soak it in vinegar, scrub it with baking soda, and buff it to shine.

Brass’s melting point is usually between 900°C and 940°C, depending on its specific alloy composition. This high melting point makes brass strong and useful in many manufacturing applications.