Corrosion resistance is critical for many materials and components, particularly in the manufacturing, construction, and transportation industries. This blog post will delve into corrosion resistance, its importance, and the factors contributing to a material’s ability to resist corrosion. Understanding corrosion resistance is essential for selecting suitable materials and ensuring your project’s longevity and performance.

What makes materials corrosion-resistant?

Corrosion-resistant materials have properties that allow them to withstand the effects of chemical reactions on their environment. Some key factors that contribute to corrosion resistance include:

Protective Coatings

Applying a protective coating, such as powder coating, paint, plating, or anodizing, creates a barrier that shields the underlying material from corrosive elements.

Alloying

Combining metals to form alloys can enhance corrosion resistance. For example, stainless steel contains chromium and has a passive oxide layer to prevent further corrosion.

Chemical Composition

The inherent chemical makeup of a material plays a significant role. Ceramics, plastics, and some metals like titanium and aluminum naturally resist corrosion due to their atomic structure.

Surface Finish

A smooth, non-porous surface finish minimizes areas where corrosion can initiate and spread. Polishing or passivating the surface improves corrosion resistance.

Environmental Conditions

Factors like temperature, pH, and exposure to moisture, chemicals, or salt water can accelerate or slow the corrosion rate. Selecting the suitable material for the application is critical.

Materials with Corrosion-Resistance Properties

Corrosion resistance is a critical factor in industrial manufacturing. Certain materials are better equipped to withstand the elements and maintain their structural integrity over time. At Prototek Digital Manufacturing, we offer a range of corrosion-resistant materials for CNC machining, fabrication, and other manufacturing processes. The following are a few materials that have corrosion resistance:

Stainless Steel

Stainless steel is a popular choice for its exceptional corrosion resistance. With a chromium-rich surface that forms a passive oxide layer, stainless steel can withstand various harsh environments, from saltwater exposure to harsh chemicals. We offer precision CNC machining of stainless steel parts in grades 304 and 316.

Aluminum Alloys

Aluminum is naturally corrosion-resistant due to the oxide layer that forms on its surface. By alloying aluminum with other elements like copper, magnesium, and silicon, we can create even more corrosion-resistant materials ideal for fabrication projects.

Titanium

Known for its high strength-to-weight ratio and excellent corrosion resistance, titanium is a top material choice for demanding applications. Whether machined or fabricated, titanium parts can endure exposure to saltwater, acids, and other corrosive elements.

Specialty Alloys

We also work with specialty alloys like Inconel for the most extreme corrosion resistance. These nickel-based alloys resist corrosion from the harshest chemicals and environments.

What types of finishes can increase corrosion resistance?

Corrosion can pose a significant problem for many manufactured parts and products. This issue can lead to premature failure, increased maintenance costs, and safety concerns. However, several types of finishes can help improve the corrosion resistance of your components. In this section, we’ll delve into some of the top options.

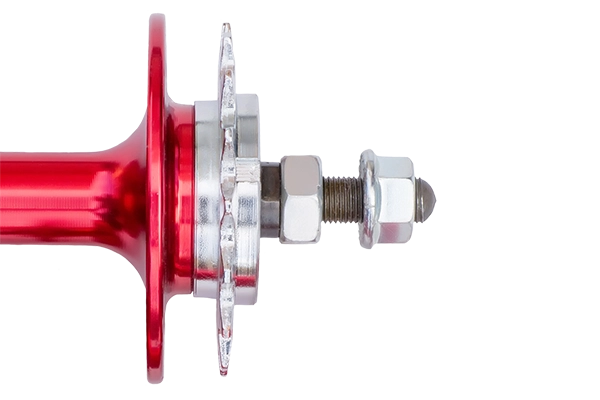

Anodizing

This electrochemical process creates a durable, corrosion-resistant oxide layer on the surface of aluminum parts. Anodizing can provide excellent protection against oxidation, chemicals, and the elements.

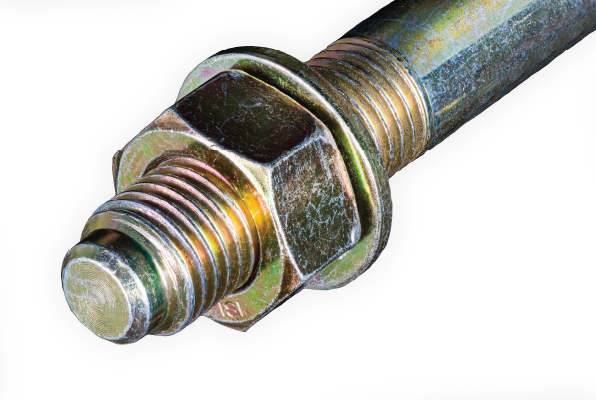

Plating

Applying a thin layer of a more corrosion-resistant metal, such as chrome, nickel, or zinc, can shield the underlying material from corrosive attack. Plating can be a prominent finish for steel, brass, and other metal parts.

Powder Coating

This dry-finishing process deposits a protective polymer coating that seals and shields the surface. Compared to traditional paints, powder coatings offer superior resistance to chipping, scratching, and weathering.

Passivation

For stainless steel parts, a passivation treatment can enhance the natural corrosion resistance by removing free iron from the surface and forming a protective oxide layer.

When does it make sense to use materials with corrosion resistance?

Corrosion presents significant challenges for many industries, resulting in costly equipment failures, downtime, and safety issues. Therefore, the selection of suitable corrosion-resistant materials is crucial. At Prototek Digital Manufacturing, we specialize in working with a wide range of corrosion-resistant materials to help our clients overcome these challenges.

So, when does it make sense to use corrosion-resistant materials? Here are a few key considerations:

Harsh Environments

If your equipment or components will be exposed to harsh chemicals, extreme temperatures, saltwater, or other corrosive elements, corrosion-resistant materials are essential to prevent premature failure.

Critical Applications

For mission-critical applications where equipment failure could lead to safety risks or significant operational disruptions, corrosion-resistant materials provide an extra layer of protection and reliability.

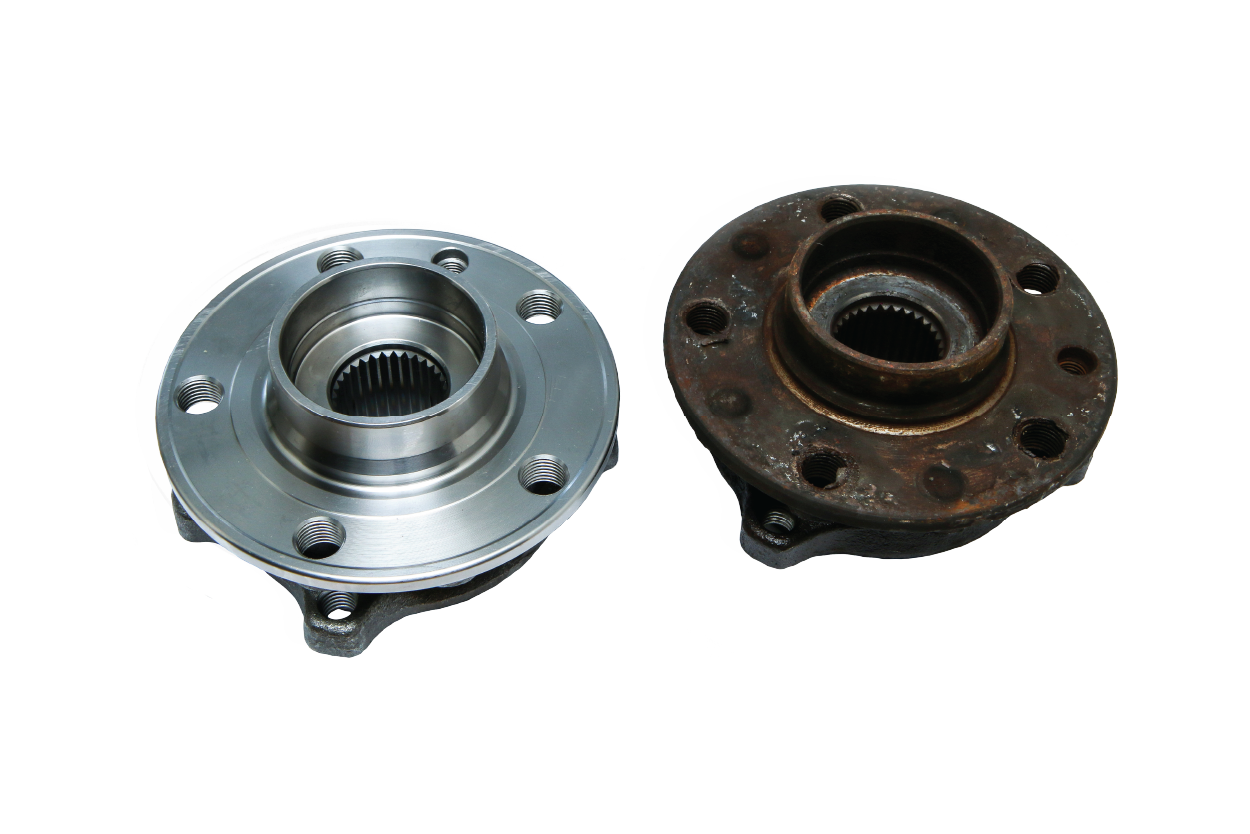

Longevity

Corrosion-resistant materials like stainless steel, titanium, and high-performance plastics can dramatically extend the usable lifespan of your parts and equipment, reducing maintenance and replacement costs.

Regulatory Requirements

Many industries have strict regulations around corrosion resistance to ensure safety and environmental compliance. Using suitable materials is often mandatory.

At Prototek, we have the expertise and capabilities to manufacture various corrosion-resistant parts and components. Therefore, please contact us today to discuss your specific needs and how we can assist you in selecting the optimal materials for your application.

FAQs

Corrosion resistance refers to a material’s ability to withstand the deterioration caused by chemical reactions with its surrounding environment. This property is crucial for components exposed to harsh conditions.

Corrosion resistance is crucial in manufacturing as it ensures the longevity and reliability of components. By mitigating the effects of corrosion, parts maintain their structural integrity, performance, and safety, ultimately reducing maintenance costs and downtime. Effective corrosion resistance is a critical consideration in the design and selection of materials, enabling manufacturers to deliver high-quality, durable products that meet the demands of diverse industries.

Aluminum is highly corrosion-resistant due to the formation of a protective oxide layer on its surface. This makes it a popular choice for various applications.

Brass is a highly corrosion-resistant alloy, making it a popular choice for various applications. Its copper and zinc composition protects against oxidation and weathering, ensuring long-lasting performance.

Stainless steel is highly corrosion-resistant due to its chromium content, which forms a protective oxide layer. This makes it a durable choice for various applications.

Corrosion resistance is indeed a chemical property. It describes a material’s ability to withstand chemical reactions that can degrade its structure over time, making it an essential consideration in manufacturing.