Macor, a remarkable glass ceramic material, has emerged as a game-changer in modern manufacturing. Its unique properties and diverse applications transform how we approach product design, engineering, and innovation across various industries. In this blog post, we’ll delve into Macor’s remarkable capabilities and explore how this material redefines what’s possible in the manufacturing landscape.

What is the history of Macor, and how is it made?

Macor is a remarkable glass-ceramic material with a long and fascinating history. In the 1950s, Corning Glass Works researchers developed this material. Its initial design was to be a high-performance electrical insulator. However, its unique properties soon led to various industrial and scientific applications.

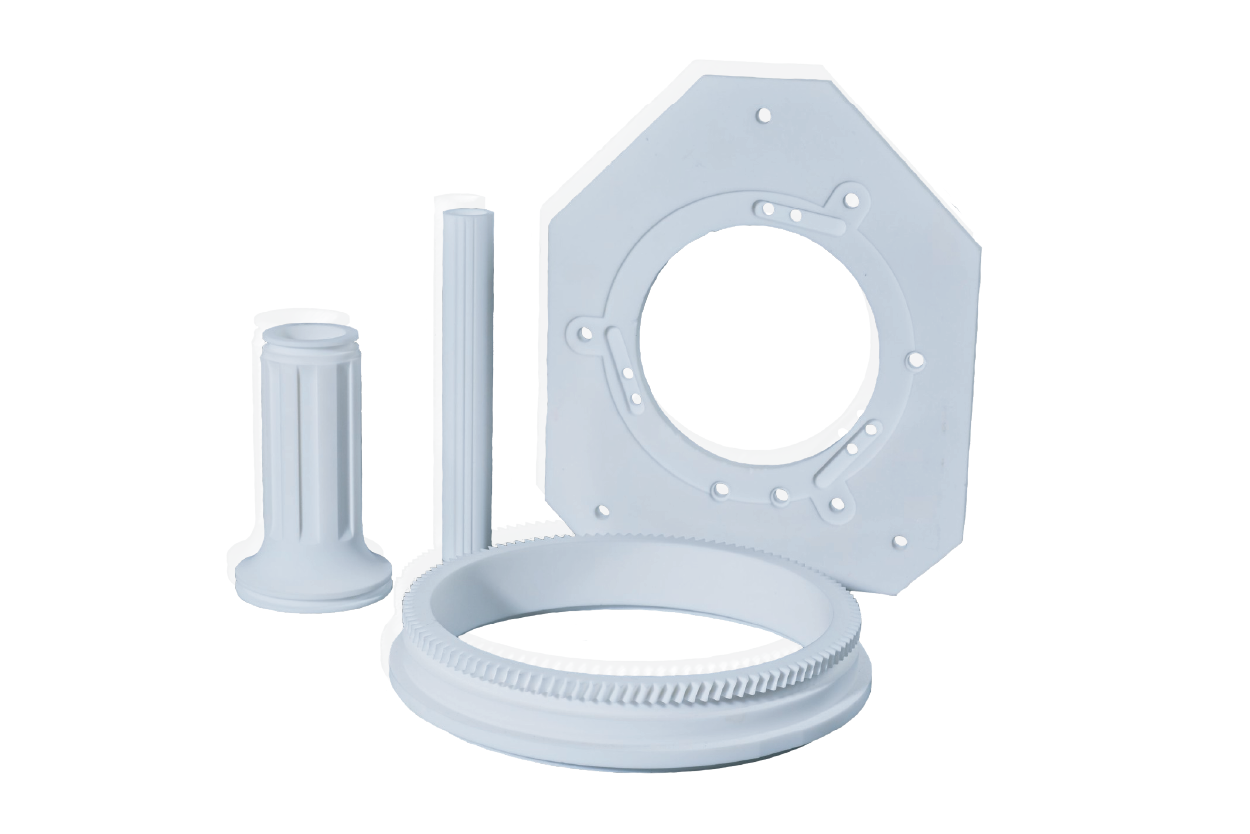

A unique manufacturing process creates Macor by combining glass and ceramic materials. First, the raw materials are carefully formulated, melted, and cast into the desired shape. As the material cools, it undergoes a controlled crystallization process, which gives it exceptional mechanical, thermal, and electrical properties.

One of Macor’s key advantages is its ability to withstand extreme temperatures. It can handle temperatures from cryogenic levels up to 1,000°C, making it ideal for high-heat environments. Examples of applications are furnaces, ovens, and semiconductor manufacturing equipment. Moreover, this material is highly machinable, allowing for the creation of complex, precision components.

Over the decades, Macor has found applications in diverse industries, from aerospace and defense to medical devices and scientific instrumentation. Its versatility, durability, and precision have made it an invaluable material for engineers and manufacturers worldwide.

At Prototek, we offer this material as part of our comprehensive range of CNC machining services. Whether you need prototypes, custom parts, or small-to-medium production runs, our team can help you harness the power of this remarkable material.

What are the mechanical properties of Macor?

Macor is a glass ceramic material with impressive mechanical properties that is suitable for a wide range of industrial applications.

One of its notable mechanical properties is its high compressive strength, which can reach up to 44962 psi (310 MPa). This exceptional strength enables Macor components to endure substantial loads and pressures. These properties make it an excellent choice for applications requiring strong and durable parts. In addition to its impressive compressive strength, it exhibits a high flexural strength of up to 14504 psi (100 MPa). This high flexural strength allows Macor to resist bending and deformation, ensuring the material’s integrity even under stress.

Another remarkable mechanical property of Macor is its low coefficient of thermal expansion, making it comparable to that of borosilicate glass. This characteristic allows it to maintain dimensional stability and resist thermal shock, making it suitable for applications involving rapid temperature changes or extreme thermal environments.

Macor’s unique mechanical properties, excellent machinability, and electrical insulation capabilities make it versatile for various industries, including aerospace, electronics, and medical device manufacturing. Its exceptional performance and reliability have earned it a reputation as a go-to material for demanding applications that require outstanding mechanical performance.

Which industries use the material?

Macor has become an increasingly popular choice for various industries due to its exceptional properties and diverse applications. This remarkable material offers a unique combination of thermal, electrical, and mechanical characteristics, making it an invaluable asset in various sectors.

Aerospace and Defense Industry

The aerospace and defense industries have also embraced Macor for its ability to withstand harsh conditions. Its resistance to thermal shock, corrosion, and radiation makes it a preferred material for components in spacecraft, missiles, and other high-performance applications where reliability and durability are paramount.

Electronics Industry

The electronics industry uses Macor for its excellent insulating properties in high-voltage and high-frequency applications. A few examples of components that use it are circuit boards, sensor housings, and vacuum tubes. This material’s low thermal expansion coefficient and high thermal stability make it a fantastic choice for applications requiring precise dimensional control, even in extreme temperatures.

Energy and Industrial Industry

The chemical processing industry also benefits from Macor’s exceptional chemical resistance, which allows it to produce specialized equipment, such as valves, seals, and reactor components, where exposure to harsh chemicals is a concern.

Medical and Dental Industry

In the medical and dental fields, Macor’s biocompatibility and machinability make it a popular choice for surgical instruments, dental implants, and other medical devices. Its non-porous surface and ease of sterilization ensure high cleanliness and safety for patient-facing applications.

Across these diverse industries, Macor’s versatility and performance-enhancing properties continue to drive innovation and push the boundaries of what’s possible in modern manufacturing and engineering. As technology advances, this remarkable material’s applications will expand, solidifying its position as a go-to choice for industries seeking reliable, high-quality solutions.

What are the benefits of using Macor for your project?

Macor is a versatile glass-ceramic composite with exceptional thermal and electrical insulation properties, ideal for high-temperature environments. Its low thermal expansion coefficient ensures dimensional stability, making it popular in electronics, aerospace, and industrial equipment. It is highly machinable and chemically inert, providing reliability in harsh environments. Incorporating Macor into your project can enhance thermal management, reliability, and precision.

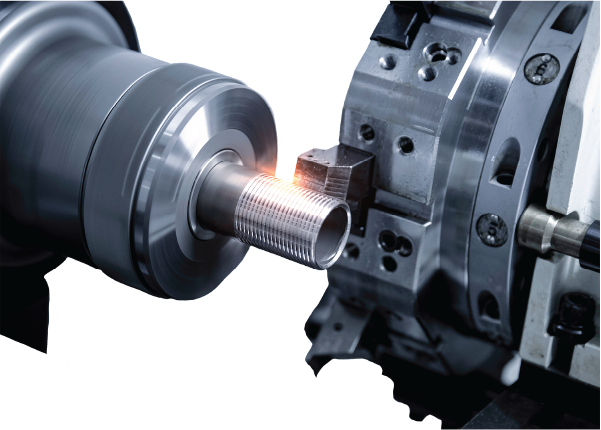

CNC Machine Shop Services

Prototek offers state-of-the-art CNC machining services to meet your precise manufacturing needs. Our skilled technicians utilize the latest CNC technology to deliver high-quality components with unparalleled precision and efficiency—Trust Prototek for all your CNC machining requirements.

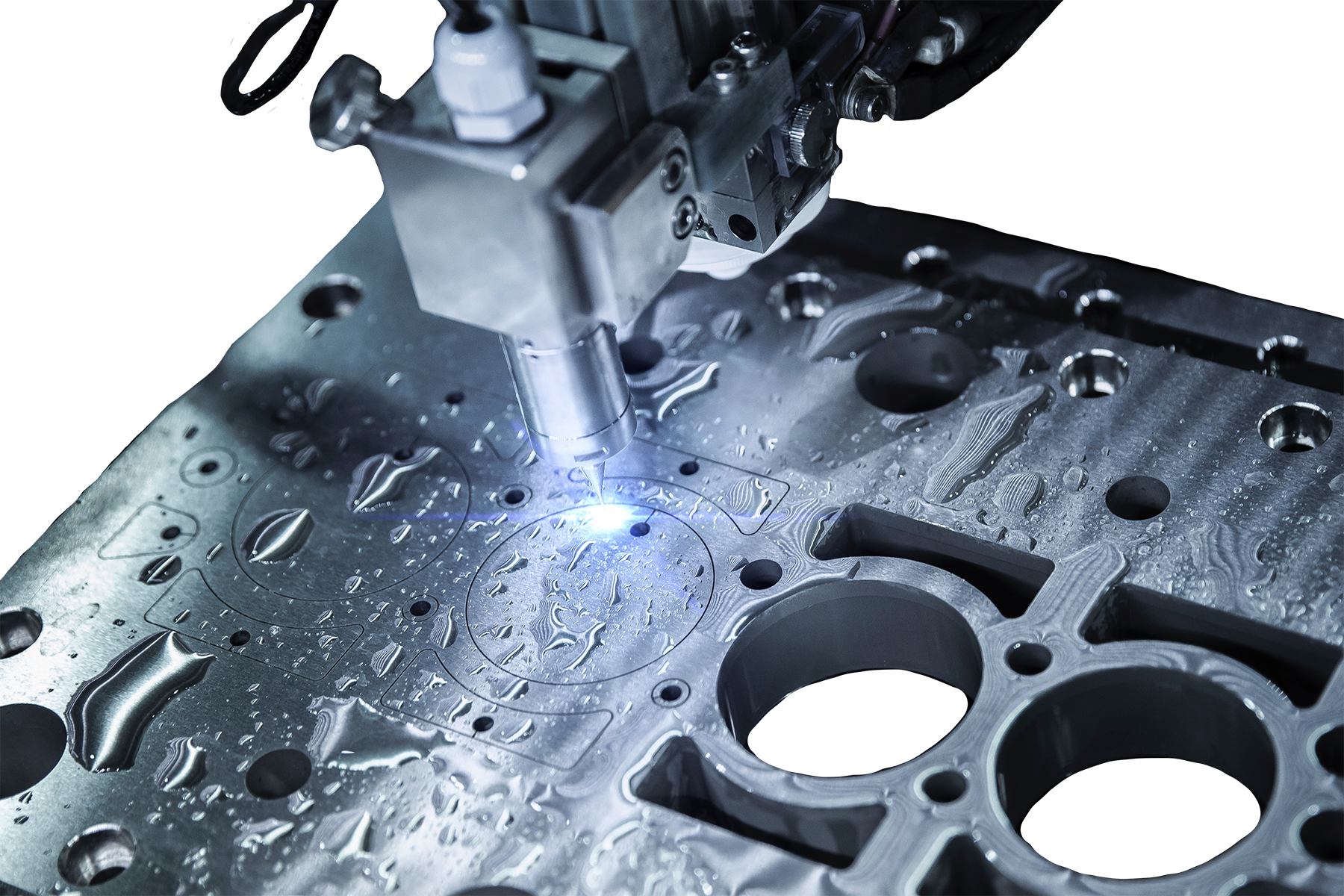

Sheet Metal Fabrication Services

At Prototek, we offer comprehensive sheet metal fabrication services to meet your manufacturing needs. Our skilled team utilizes the latest technology and techniques to deliver high-quality, precision-engineered components. From prototyping to production, trust Prototek to bring your ideas to life.

FAQs

It is a machinable glass-ceramic material known for its exceptional thermal, electrical, and mechanical properties, making it ideal for various industrial applications.

Due to its exceptional thermal and mechanical properties, it is a machinable glass-ceramic material widely used in electronics, aerospace, and medical devices.

Applications demanding high thermal and mechanical stability can use this material. Some examples are semiconductor equipment, medical devices, and aerospace components.

It has an impressive melting point of around 1,400°C (2,552°F), making it suitable for high-temperature applications.

Components made from this material can be finished using various methods, including polishing, grinding, and precision machining, to ensure a high-quality surface.