Ram EDM, or sinker EDM, is a specialized manufacturing process that utilizes electrical discharges to remove material from a workpiece. This precise and versatile technique allows for the creation of complex, intricate parts across various industries. By harnessing the power of controlled electrical sparks, it can machine challenging materials and geometries that are difficult or impossible to produce through traditional machining methods. In this blog post, we’ll explore the fundamentals of this EDM, its key benefits, and how modern manufacturing can leverage it to drive innovation.

How does ram EDM work?

Ram EDM (electric discharge machining) is a manufacturing process that utilizes electrical discharges to remove material from a workpiece. This non-contact machining technique is particularly effective for creating complex shapes and features in hard, conductive materials.

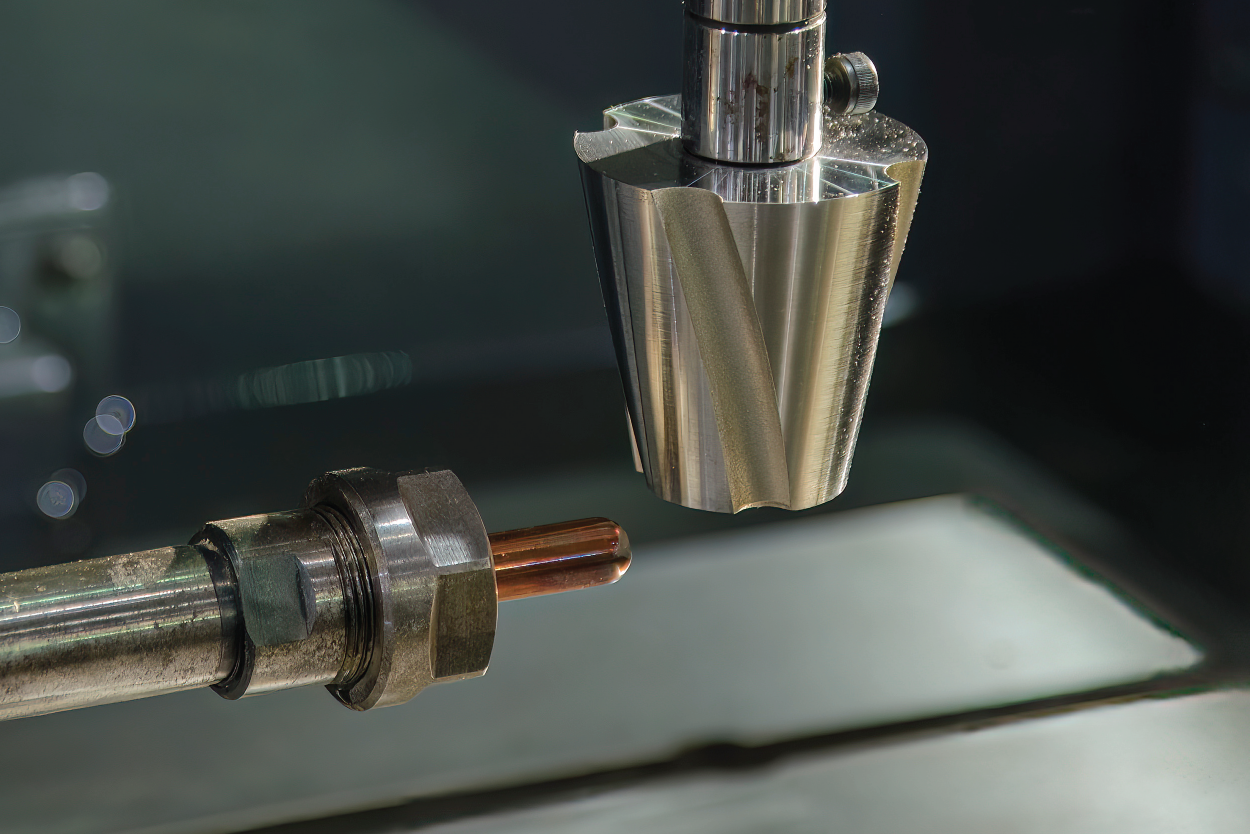

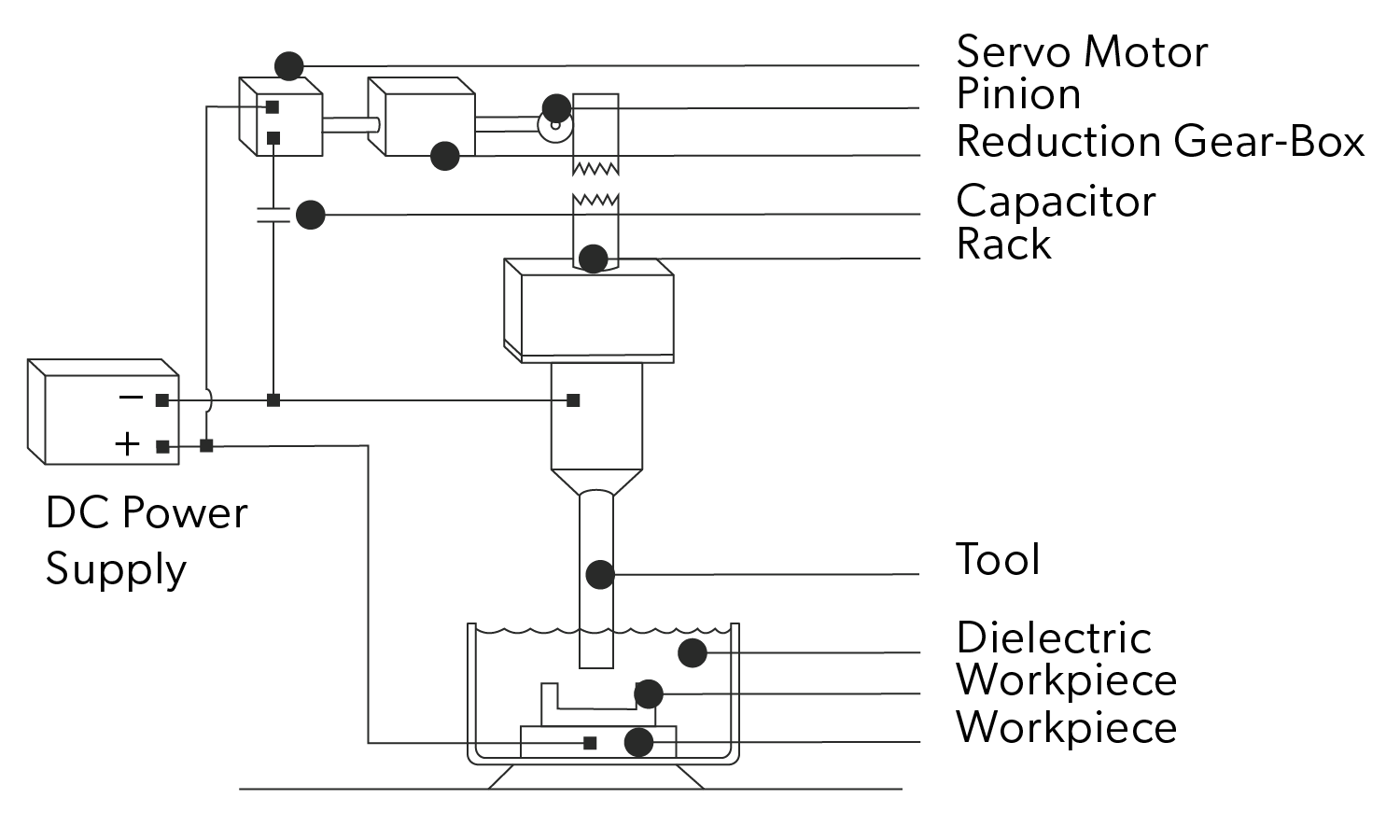

The process involves submerging the workpiece and an electrode tool in a dielectric fluid, typically deionized water or oil. An electrical potential is then applied between the electrode and the workpiece, generating a series of rapid, controlled electrical discharges. These discharges erode the material from the workpiece, allowing the creation of the desired shape.

The electrode, the mirror image of the desired feature, is slowly lowered towards the workpiece, maintaining a precise gap between the two. Gradually, the material is removed as discharges occur, creating the final part geometry.

Ram or sinker EDM is a versatile process capable of producing intricate features, complex shapes, and high-precision components across various industries, including aerospace, automotive, and medical device manufacturing.

What are the benefits of ram EDM?

Ram EDM is a precise and versatile manufacturing process that offers numerous benefits for various industries. One of its primary advantages is creating complex, intricate parts with exceptional accuracy and precision. Moreover, the method uses electrical discharges to erode the material, allowing for the production of parts with complicated geometries and tight tolerances that would be challenging or impossible to achieve through traditional machining methods.

Another critical benefit is its ability to work with various materials, including hard, brittle, or conductive materials that may be difficult to machine using other techniques. Consequently, this makes it an ideal choice for the production of components in industries such as aerospace, automotive, and medical device manufacturing.

Additionally, it is a highly efficient and cost-effective manufacturing process. Eliminating the need for physical contact between the tool and the workpiece reduces the risk of tool wear and breakage, lowers production costs, and increases client productivity.

What are the applications of ram EDM?

Ram EDM, or Ram Electrical Discharge Machining, is a versatile manufacturing process with many applications. Some critical applications of this capability include:

Precision Machining of Complex Parts

It excels at producing intricate, detailed parts with tight tolerances and complex geometries. These would be difficult or impossible to achieve through traditional machining methods.

The Machining of Hard and Conductive Materials

Ram EDM can effectively machine hard, conductive materials such as tungsten carbide, titanium, and Inconel that are challenging to machine using conventional techniques.

Mold and Die Making

Ram Electrical Discharge Machining (EDM) is a precise manufacturing process used to produce intricate molds and dies for applications like injection molding and stamping. This method allows for creating highly detailed features and complex cavities, making it essential in the manufacturing industry.

Aerospace and Automotive Compoents

It specializes in manufacturing aerospace and automotive parts. Using advanced EDM techniques to create high-quality, complex components like turbine blades and fuel injectors.

Medical Device Parts

Ram EDM (Electrical Discharge Machining) is ideal for producing intricate medical devices, implants, and surgical instruments. This advanced process creates precise components essential for medical applications, making it a valuable technology for the healthcare industry.

Why choose this capability for your project?

At Prototek Digital Manufacturing, we offer advanced Electrical Discharge Machining (EDM) services. Our ram EDM capabilities produce intricate parts with exceptional accuracy, complex geometries, fast turnaround, and work with versatile materials. We are committed to providing uncompromising quality to support the success of your project.

FAQs

It is a specialized manufacturing process that uses electrical discharges to shape and cut conductive materials.

It can precisely cut various conductive materials, including metals, alloys, and some ceramics.

Aerospace, automotive, and medical industries use this capability.

It is also known as sinker EDM.