Steel is one of the world’s most valuable and widely used materials. It is substantial, durable, and affordable, crucial for modern buildings, manufacturing, and everyday life. This material shapes our cities through tall buildings and is essential for the cars we drive. It helps create our environment and inspires new possibilities.

This blog post will examine the history of steel, a material that has influenced industries and societies around the globe. Knowing its properties and uses is essential not only for today and tomorrow but also for appreciating the legacy of this remarkable material.

How is steel made?

Steel is a common material used in many industries. Steel mills create it by melting iron ore, coal, and limestone in a furnace at about 1,500°C (2,700°F). This melting process is called smelting, and it produces molten pig iron.

After that, the mill refines the molten pig iron in a basic oxygen furnace or an electric arc furnace. This step removes carbon, silicon, manganese, phosphorus, and sulfur impurities. The mill adds alloying elements such as chromium, nickel, and molybdenum to give the steel unique properties.

Once the steel has the correct chemical composition, the mill casts it into ingots or shapes it into slabs, billets, or blooms. These semi-finished products then go to rolling mills, which turn them into final products like sheets, bars, pipes, and structural shapes.

The mill uses strict quality control measures throughout the steel-making process to ensure the final product meets the required standards. This attention to detail makes it reliable and versatile, suitable for skyscrapers, bridges, automobiles, and household appliances.

What are the mechanical properties of steel?

Many industries use steel because of its strong mechanical properties. It is known for being strong yet lightweight, stiff, ductile, rigid, and easy to weld.

Corrosion Resistant

This material is known for its high durability, strength, and corrosion resistance. Its ability to maintain integrity over extended periods makes it ideal for use in harsh environments and outdoor applications.

Ductility

Ductility is the ability of a material to bend and change shape without breaking. It is a valuable quality in manufacturing when it comes to shaping the material into complex forms.

Hardness

Hardness is an important property of steel. It helps the material resist dents, scratches, and wear, which is essential for parts that face a lot of friction and impact. Heat treatment can improve the hardness of this material for specific uses.

Strength

One of steel’s main properties is its strength. It has high tensile, compressive, and shear strengths, making it ideal for structures that support heavy loads and machinery and tools. Its strength depends on its chemical makeup.

Weldability

Weldability is an essential quality of metals when making parts. It shows how easily and firmly different pieces can be joined together. Weldability depends on factors like the metal’s composition, the welding method used, and the specific requirements of the parts.

What types of steel are there?

Steel is a valuable and widely used material in manufacturing and construction. Many types of steel exist, each with its properties and uses. This section will explore these different types.

Carbon Steel

Carbon steel is a widely used material containing different amounts of carbon. It is strong, durable, and easy to produce at a low cost. Many industries, such as construction, automotive, tools, and machinery, commonly use this material.

Stainless Steel

Stainless steel is a strong material because it contains chromium, which makes it resistant to rust and corrosion. Because it can handle harsh conditions, this exceptional material is an excellent choice for kitchen appliances, medical equipment, and outdoor furniture.

Steel Alloy

The makeup of steel alloys includes adding nickel, chromium, or molybdenum to this material. These metal additives create stronger steel, durability, and wear and tear resistance. Industries like aerospace, automotive, and energy use these materials.

Tool Steel

Tool steel is a metal that stays hard and strong even at high temperatures. It is used to make trimming tools, molds, and other industrial equipment.

Which industries use steel?

Steel is essential in many industries, driving innovation and success. Prototek, a leader in digital manufacturing, takes advantage of its unique qualities to help customers create high-quality products that fit their needs.

Steel plays a vital role in our daily lives. We see it in skyscrapers that define our skylines and cars that transport us. The construction industry uses steel for its strength, durability, and cost-effectiveness in structural beams and reinforcing bars. Showing how vital our work is in the steel industry.

The automotive industry also uses steel to make vehicle frames, body panels, and engine parts. Its strength and light weight make it perfect for this fast-paced sector, which affects how cars are designed and performed.

Steel is not just standard in energy, defense, and consumer goods industries. It is an essential material. Power plants, military equipment, and home appliances all rely on steel. Moreover, the agricultural sector uses it for farm equipment and storage silos, proving its widespread use.

Steel is more than just a resource; it drives innovation, productivity, and progress across many fields. Its unique properties and versatility inspire many new ideas and continue to advance various industries.

What are the benefits of using this material?

Steel is a strong and durable material used in many areas. Its high strength compared to weight, resistance to rust, and ability to shape it into different forms make it perfect for building, manufacturing, and infrastructure projects. Steel is also recyclable and sustainable, which adds to its popularity for modern uses.

Cost-Effectiveness

Steel is not just a high-performing material but also a wise investment. Its balance of performance and cost makes it a popular choice, adding value to your projects and providing a sense of reassurance about your investment.

Recyclability

This material is easy to recycle. Reusing and repurposing it reduces waste and helps make CNC machining and sheet metal fabrication more sustainable.

Strength and Durability

Steel is a solid and resilient material, making it ideal for applications that require high load-bearing capacity and long-lasting performance.

Versatility

Fabricating it by shaping and customizing it to meet a variety of design and functional requirements makes it a popular choice across industries.

Why choose this material for your project?

Steel is a strong and long-lasting material with many benefits for your project. Its excellent strength-to-weight ratio makes it suitable for many uses. This material is also very rust-resistant, which helps it last a long time. Additionally, it is recyclable, eco-friendly, and fits well with sustainable manufacturing. With Prototek’s CNC machining and sheet metal fabrication skills, we can help you make the most of steel to bring your ideas to life.

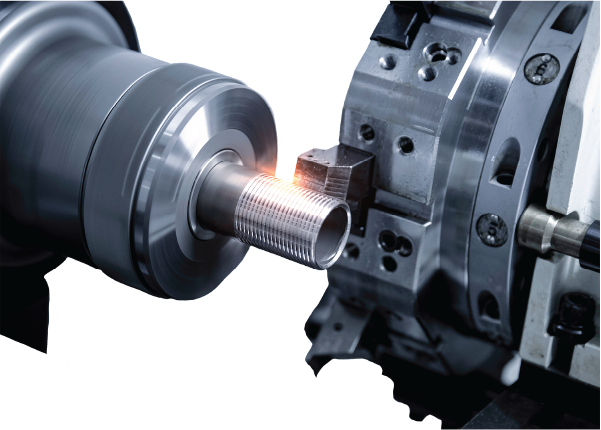

CNC Machine Shop Services

Prototek offers state-of-the-art CNC machining services to meet your precise manufacturing needs. Our skilled technicians utilize the latest CNC technology to deliver high-quality components with unparalleled precision and efficiency—Trust Prototek for all your CNC machining requirements.

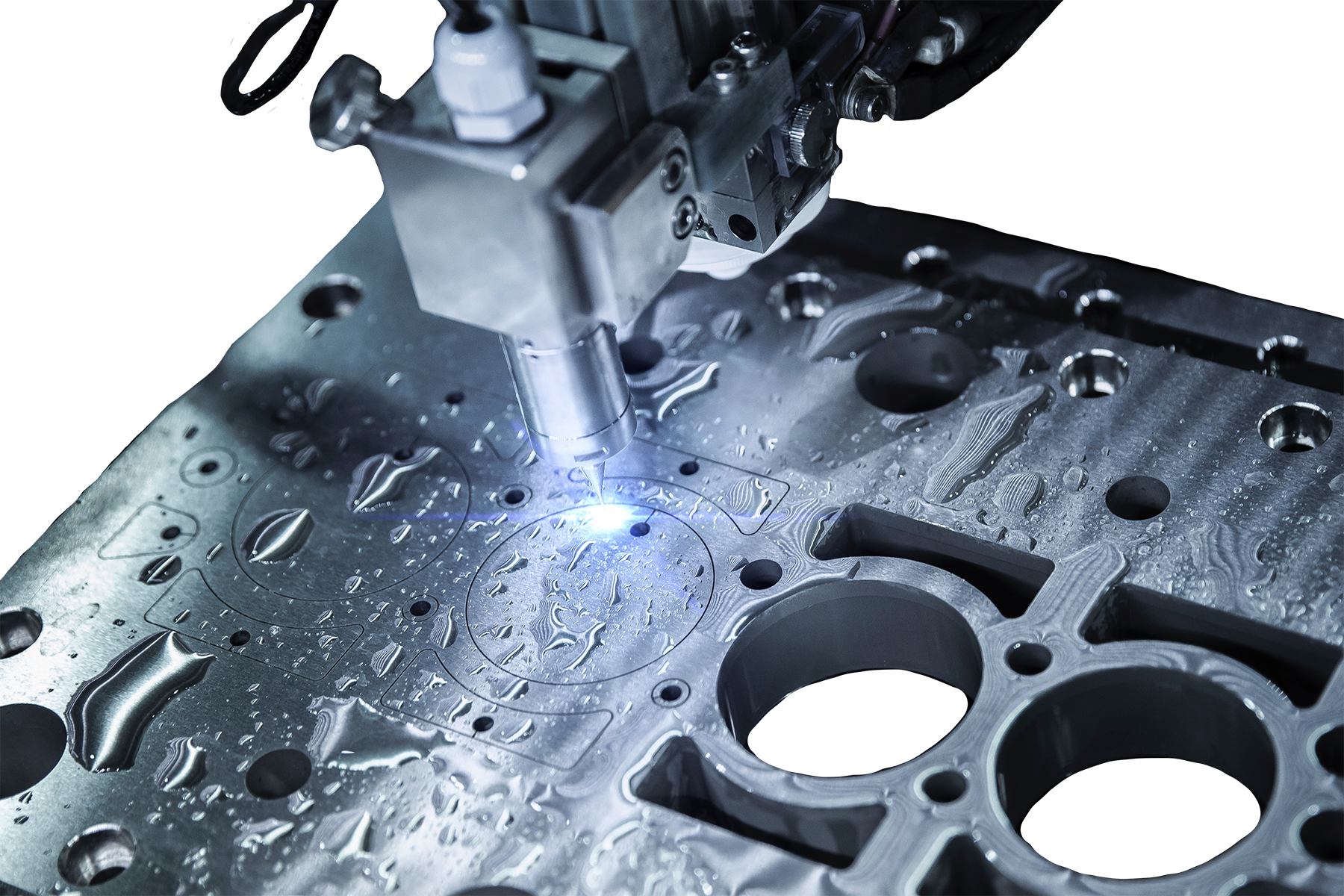

Sheet Metal Fabrication Services

At Prototek, we offer comprehensive sheet metal fabrication services to meet your manufacturing needs. Our skilled team utilizes the latest technology and techniques to deliver high-quality, precision-engineered components. From prototyping to production, trust Prototek to bring your ideas to life.

FAQs

It is a strong, durable, versatile metal alloy composed primarily of iron and carbon. The construction, transportation, and various other industries use this material.

It can rust, but the degree of rusting depends on the type of steel and environmental factors. Proper maintenance and protective coatings can help prevent or minimize its corrosion.

It is a magnetic material, meaning it can be attracted to magnets. This property is due to the iron content in the material, which gives it its magnetic properties.

It is versatile in various industries, including construction, automotive, aerospace, machinery, and infrastructure development.

At Prototek, we offer precision CNC machining and sheet metal fabrication.