Waterjet cutting is a versatile and adaptable technology that utilizes a high-pressure stream of water to cut through various materials. Additionally, it is a popular subtractive manufacturing process that offers numerous benefits, including high accuracy, the ability to create complex shapes, and minimal material waste. This article will provide an overview of waterjet cutting, including its operation, applications, and advantages.

How does it work?

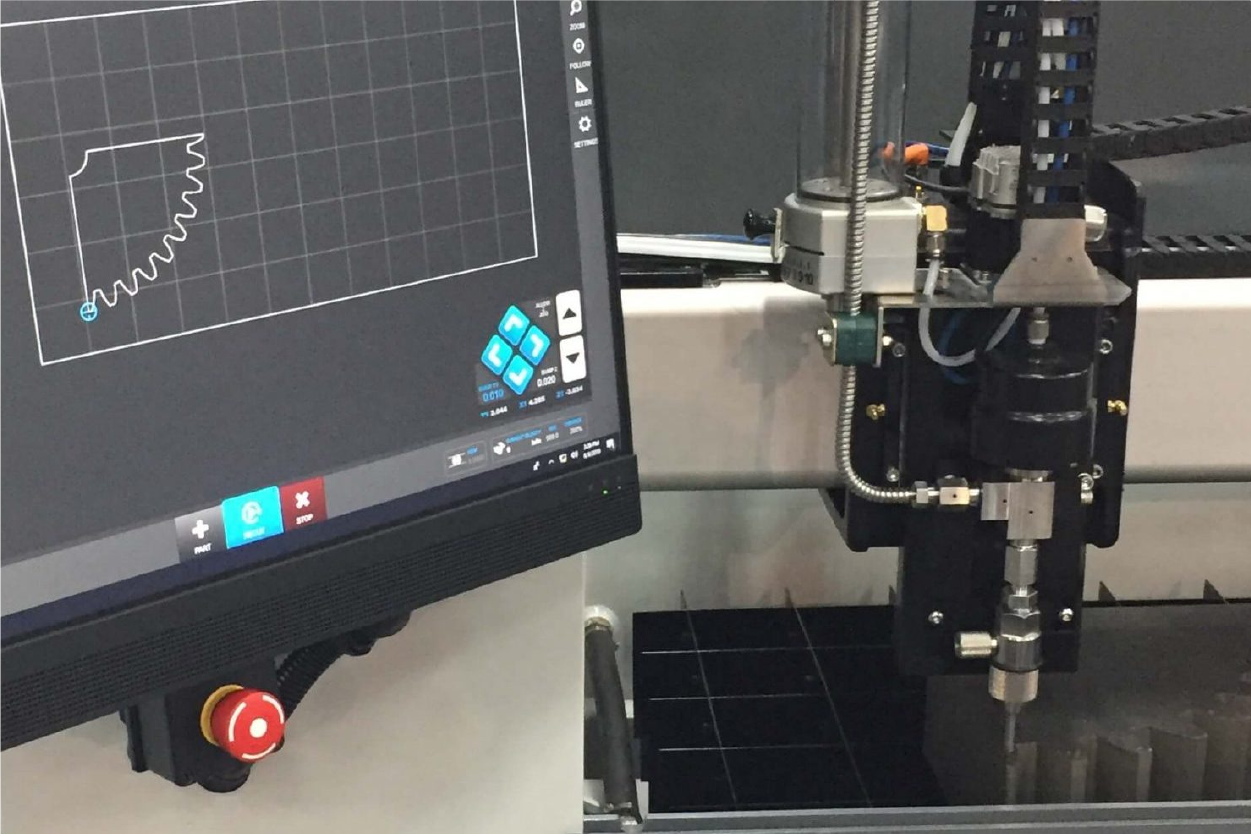

Waterjet cutting is an advanced method of cutting materials using a high-pressure stream of water. The process entails pressurizing water to extremely high levels, sometimes up to 60,000 pounds per square inch, and then directing the resulting stream through a small nozzle at high speeds. Sometimes, an abrasive substance such as almandine garnet, a type of sand, is added to the water to increase its cutting power.

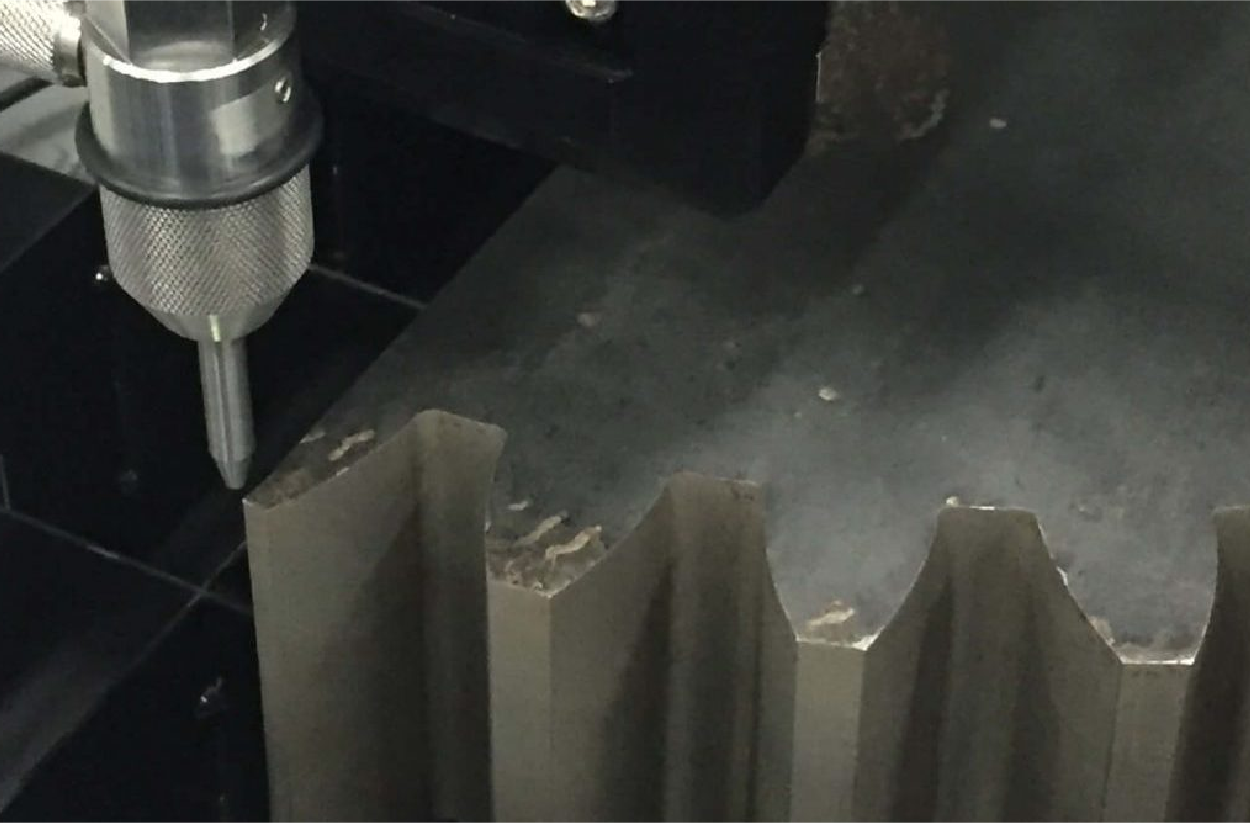

The mixing of water and abrasives results in stream cuts of the material. Due to the water’s high-pressure and abrasive properties, it effectively erodes and cuts through the material, resulting in precise and clean cuts. This method can cut hard materials like metal, stone, glass, and composites. Additionally, it is widely known for its ability to produce intricate shapes with minimal material wastage.

Waterjet Cutting Applications

Waterjet cutting is a versatile and precise manufacturing process that finds applications across various industries. Our state-of-the-art waterjet technology can produce intricate parts for the aerospace and automotive industries and custom fabrication for architecture and art, delivering exceptional results. Additionally, this technology can cut through diverse materials, including metals, composites, and stone, providing unparalleled flexibility and efficiency in your manufacturing workflow.

Advantages of Waterjet Cutting

Waterjet cutting is renowned for its exceptional accuracy, as the narrow and focused stream of water allows for precise cutting through various materials, including metals and composites. This high level of precision enables the production of intricate and complex shapes without additional finishing processes. Additionally, waterjet cutting is environmentally friendly, as it produces minimal waste and does not generate any harmful byproducts or fumes.

Furthermore, the non-contact nature of waterjet cutting minimizes the risk of heat-affected zones, material distortion, or mechanical stress, making it an ideal method for cutting sensitive materials. The absence of tool-to-material contact also reduces the likelihood of contamination, ensuring the integrity of the cut materials. These characteristics make waterjet cutting a preferred choice for applications requiring precision and environmental consideration.

Is waterjet cutting right for my parts?

Waterjet cutting is a versatile and precise manufacturing process that offers many benefits over traditional cutting technologies. It can cut through a wide range of materials, including metals, plastics, and composites, which makes it a popular choice for many industries, ranging from aerospace to art and architecture. Whether you need to produce complex components or require highly accurate cutting technology, waterjet cutting is a powerful and efficient method to help you achieve your manufacturing goals.

Are you ready to start your project?

FAQs

Waterjet cutting is a versatile manufacturing process that utilizes a high-pressure stream of water, often combined with an abrasive, to precisely cut through a wide range of materials.

Waterjet cutting is an incredibly versatile manufacturing process that utilizes a high-pressure stream of water to cut through a wide range of materials precisely. Mixing the water with an abrasive substance, typically garnet,increasese its cutting power. Therefore, this focused, high-velocity stream can effortlessly slice through metals, plastics, composites, and even stone, making it a valuable tool for intricate and complex part fabrication.

Waterjet cutting is a versatile manufacturing solution that enables precise cutting of various materials, such as metals, plastics, composites, stone, and even glass. Additionally, it offers the flexibility to work with multiple materials, making it an ideal choice for diverse manufacturing needs.

Waterjet cutting is a versatile technology used in various industries, such as aerospace, automotive, construction, metal fabrication, and stone/tile manufacturing. Its precision and ability to cut a wide range of materials make it a valuable tool for numerous applications.