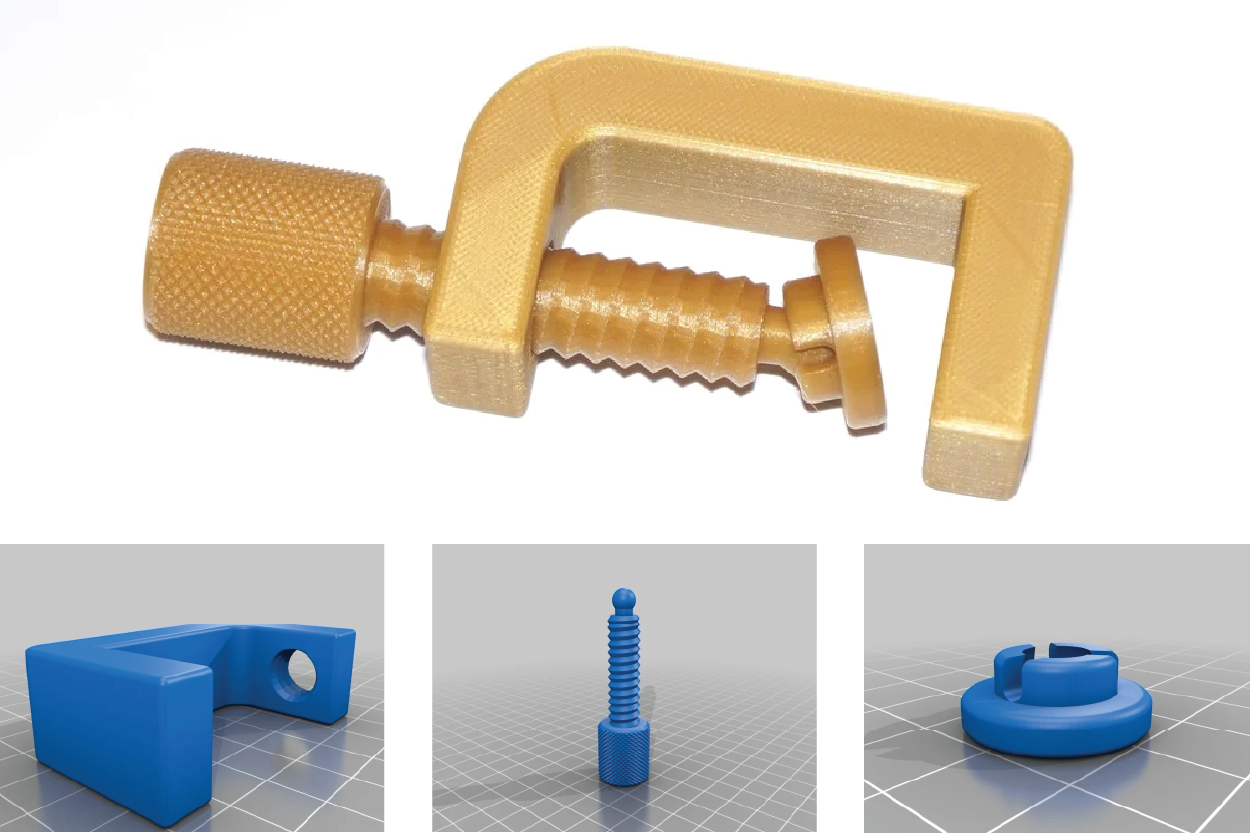

STL files are essential for 3D printing. They are the standard format used to turn 3D models into tangible objects. If you are interested in or work with additive manufacturing, understanding STL files is necessary. This post will discuss why these files are a key part of 3D printing and how they help create complex, custom parts and products.

What are STL files?

STL files show the surface shape of a 3D object, which is essential for digital manufacturing. Many 3D modeling programs and 3D printers support this file type, making sharing and producing models easy.

What is the history of STL Files?

The STL file format, created in 1987 by 3D Systems, a leader in 3D printing, is designed for simplicity. It allows users to represent the surface shape of 3D objects without needing complicated data structures. This ease of use has made these files the standard for 3D printing and computer-aided design (CAD), reassuring users that they can efficiently work with them.

Initially, STL documents were primarily used for rapid prototyping and 3D printing, making it easy for designers and engineers to share and work on 3D models. However, the format has evolved over the years, improving file size and accuracy and supporting color and texture information. This evolution has expanded the possibilities of 3D printing, making them even more essential for additive manufacturing.

How do STL Files work?

STL files are a standard format used in 3D printing and computer-aided design (CAD) software. They show the surface shape of a 3D object using triangles. STL files work with many programs, making it easy to share 3D model data across different software and manufacturing processes. They are an essential part of the digital manufacturing process.

What programs open STL documents?

STL files, commonly used in 3D printing and computer-aided design (CAD), are opened and viewed using various software programs. Some popular options include:

- 3D modeling and CAD software like AutoCAD, SolidWorks, Fusion 360, and FreeCAD

- 3D printing slicing software like Cura, Slic3r, and PrusaSlicer

- General 3D viewing and editing software like Blender, MeshLab, and 3D Builder

- Online 3D file viewers and editors like Sketchfab and Tinkercad

These programs are not just tools for opening and viewing STL files. They are crucial to the 3D printing and design workflow. Using these programs to open, view, and sometimes edit these files empowers you to bring your digital designs to life.

How do you create and edit STL documents?

The following steps will outline creating your object using 3D modeling software.

Step 1: Design Your 3D Model

To create your 3D model, use 3D modeling software like CAD or sculpting tools. When making an STL file for 3D printing, keep these essential points in mind:

- Geometry: Ensure the part is watertight and manifold, with no gaps or overlapping surfaces. It will help ensure a successful print.

- Wall Thickness: Keep the wall thickness consistent for good strength and print quality.

- Overhangs: Reduce unsupported overhangs, as they can be hard to print without support.

- Holes and Clearances: Plan for hole sizes and clearances needed for assembly or functionality, considering 3D printing tolerances.

- Surface Finish: Orient the part to improve its surface finish.

Following these guidelines will help improve your 3D printing results.

Step 2: Export the STL File

When your 3D model is complete, export it as an STL file. The steps may vary by software, but you should look for an “Export” or “Save As” option to choose the STL format.

Step 3: Inspect and Validate the STL File

Open the exported STL file in a 3D viewer or STL editing software. Check the model carefully. Ensure it has no missing or overlapping faces and is manifold and watertight.

Step 4: Edit the STL File (if necessary)

If you find problems with the STL document, such as missing or overlapping faces, use STL editing software to fix them. This step might include repairing the mesh, smoothing surfaces, or changing the overall design.

Step 5: Optimize the STL File

Depending on how you plan to use it, you may need to optimize the STL file. It could mean reducing the file size, adjusting the resolution, or preparing the model for 3D printing or other manufacturing processes.

By following these steps, you will confidently create and edit STL files, allowing you to bring your digital designs to life through 3D printing and manufacturing.

Are you ready to start your project?

FAQs

This file format is the primary 3D modeling file type for 3D printing, and various 3D printing software and hardware support it.

CAD software like SolidWorks, Fusion 360, and AutoCAD commonly create these file types for 3D printing.