Online Machining Services

Parts in days anywhere in the USA.

Our online machining services offer:

- Facilities Throughout the USA

- Milling, Routing, Turning, and Wire & Sinker EDM

- Machined Metals, Plastics, Foam, and Other Materials

Quality Matters | AS9100D Certified, ISO 9001:2015, ISO 13485:2016, & ITAR Registered

*Not all locations have all certifications and registrations. Parts requiring these will be made at facilities with the correct credentials.

Our Digital Manufacturing Process is Simple.

Upload a CAD file and request a quote.

Our team starts production after finalizing project specifications and accepting the quote with you.

When the part has been completed and finished, it passes through quality control.

After your part goes through quality control, our team ships the part(s) to you.

Online Machining Services

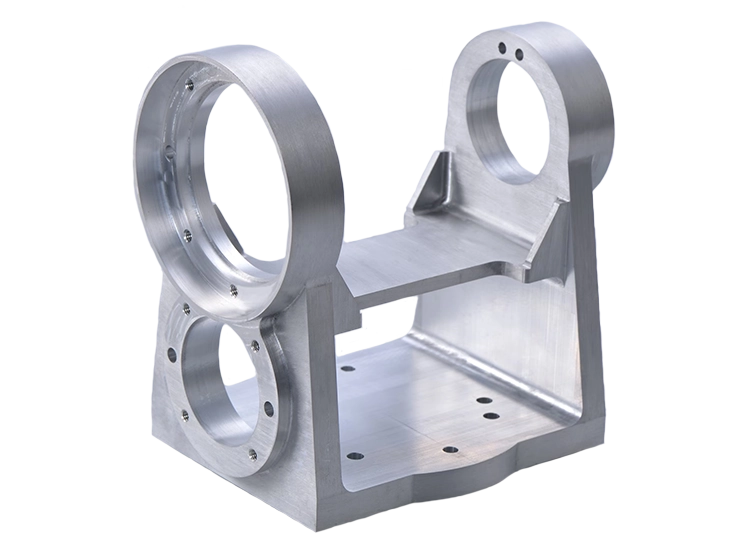

Prototek’s high-precision online machining service lets customers quickly and easily find CNC options nearby. Customers can upload designs, select materials, and receive pricing and lead time information from their home or office through online manufacturing. We can handle various manufacturing needs with multiple machines, including CNC machines. Additionally, the online platform empowers customers to find machining services that meet their materials, precision, and project size requirements. Furthermore, our machining online service streamlines the process, saving time and reducing costs by eliminating the need for in-person meetings and site visits. Ultimately, with Prototek’s online service, customers can easily find the CNC services they need.

What is CNC?

Computer Numerical Control, or CNC for short, refers to a high-precision manufacturing process involving computer technology to control machinery and tools used in manufacturing. Utilizing pre-programmed software, CNC machines can accurately transform raw materials into custom parts. Consequently, CNC technology has revolutionized the manufacturing industry, making it possible to produce complex and precise parts with minimal human input. As a result, efficiency has increased, and the likelihood of errors has decreased.

Customize like never before.

Harnessing the power of cutting-edge CNC machining services, we bring your unique designs to life with precision and finesse. Our process guarantees impeccable accuracy, ensuring the transformation of your vision into a tangible reality with the utmost attention to detail.

Precision and perfection.

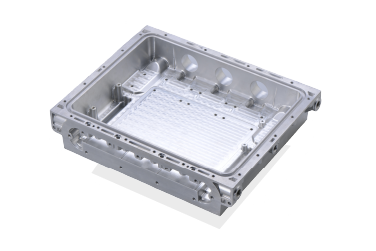

No more hit-or-miss! CNC machines carve out complex designs with hair-splitting precision. From tailor-made engine components to aerodynamic body parts, perfection is just a program away.

Consistency is key.

With each batch and every individual part, CNC machining guarantees that each custom component is a replica of the original design. Consistency is our hallmark.

Online machining.

Transform your design process with our high-precision online machining platform. You can obtain quotes, upload designs, and receive precision parts with just a few clicks.

From prototype to production.

Whether a one-off prototype or a full-scale production, CNC online machining powers through the process, ensuring your project is a showpiece!

How To Start Your CNC Project

Here are the steps used at Prototek to turn your designs into a finished product through precision CNC machining:

- Create your part using computer-aided design (CAD) software and save it as a vector file. Standard formats include DXF, AI, BMP, CDR, DWG, PDF, STL, and SVG. Preferred files are Solid, STEP, and DFX, which ensure compatibility with different CNC machines and software programs.

- Upload your CAD file to our website using our engineer-assisted quoting platform. Our engineers will review your request for a quote, contact you with questions, and quote the project. Once you accept the machining quote, we can proceed to the next step.

- Once you accept the job quote, Prototek will convert your CAD file to G-Code using CAM (computer-aided manufacturing) software. This G-Code, a machine-readable language, plays a pivotal role in guiding the CNC router during cutting, ensuring the precise execution of your design.

- Prototek will start the precision CNC machining process by executing the CNC program. The machine will adhere to the pre-programmed toolpath, cutting the material based on the design specifications.

- After machining, the finished part may need additional steps such as sandblasting, powder coating, anodizing, graining, electroplating, painting, and polishing to achieve the desired outcome and aesthetics.

- Once the finishing process is complete, we will carefully package your project and ship it to you.

Our Online Machining Capabilities

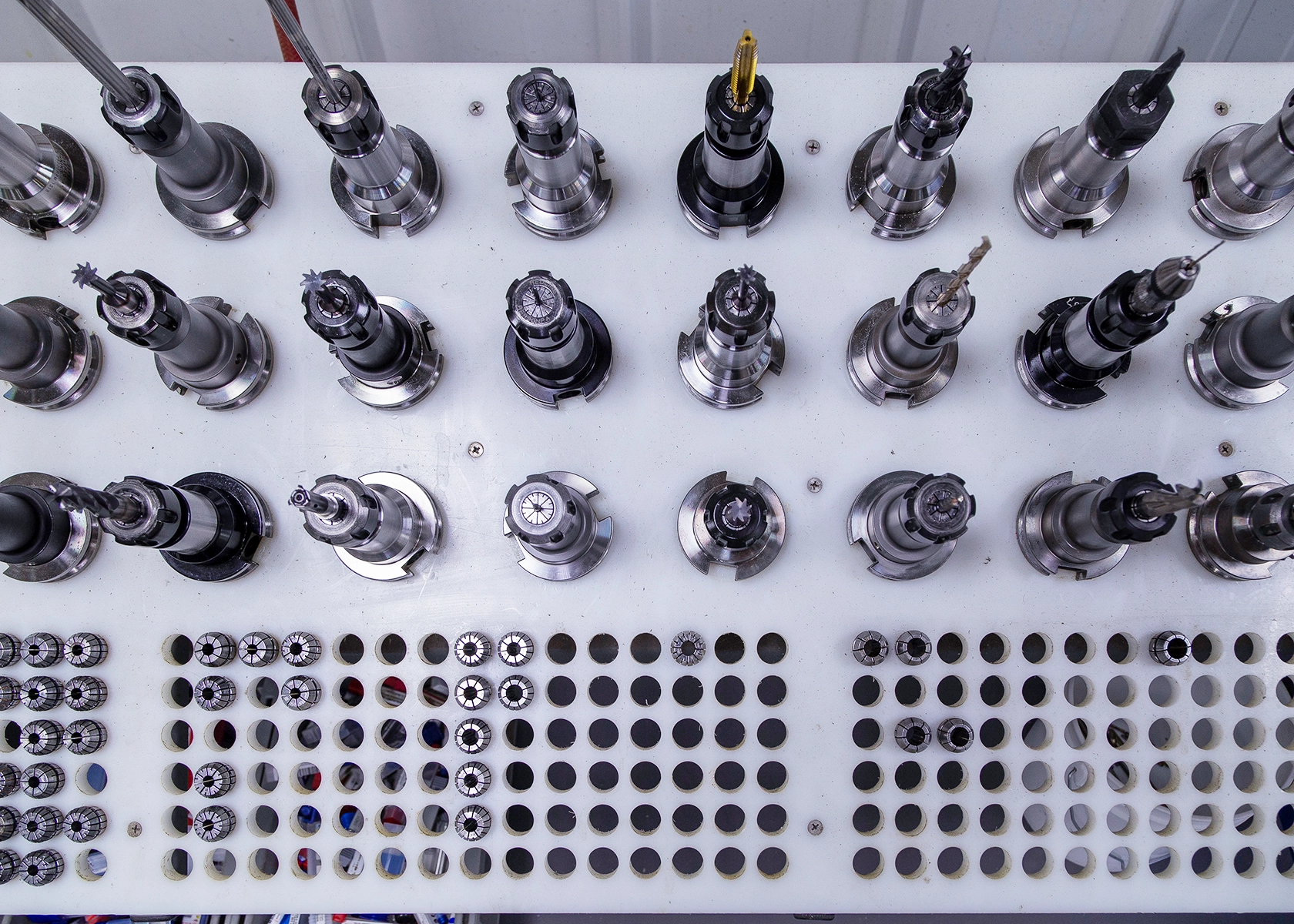

Prototek specializes in precision machining services provided by a team of skilled professionals utilizing advanced technology. Our services include CNC lathes, milling, routing, wire and sinker EDM, manual machinery, and cutting-edge 9-axis mill turns. You can trust us to deliver exceptional results with our expertise and equipment.

OEM

Akira Seiki, Atrump, Bridgeport, Brother, Daewooo, DMG Mori, Doosan, Haas, Hurco, Kent USA, Lagun, Matsuura, Mazak, OKK, Sharp, Sodick

Lead Time

5 – 22 Days

Max Dimensions

84 x 34 x 30 in (2133.5 x 863.5 x 762 mm)

Prototek has many machines with different dimensions. This is the largest dimension available.

Material

Metals: Aluminum, Bearing Bronze, Brass, Bronze, Carbon Steel, Copper, Phosphor Bronze, Silicon Aluminum Bronze, Stainless Steel, Steel, Titanium

Plastics: ABS, Acrylic, Acetal, HDPE, Nylon, PEEK, Polycarbonate, Polypropylene, Radel, Ultem

OEM

KOMO

Lead Time

5 – 22 Days

Max Dimensions

48 x 120 in

Material

Plastic, composites, wood, soft metals.

OEM

Acra-Turn, Atrump, Daewooo, Doosan, Enco, Haas, Hardinge, Hurco, Mazak, Trak Lathe

Lead Time

5 – 22 Days

Max Dimensions

XYZ | 84 x 34 x 30 in

Diameter | 12 in

Swing | 26 in

Material

Aluminum, Inconel, Stainless Steel and Steel, Plastics, Titanium, and Other Materials

OEM

Aluminum, Inconel, Stainless Steel and Steel, Titanium, and Other Materials

Lead Time

5 – 22 Days

Max Dimensions

31.5 x 23.6 x 31.5 in thick

Material

Aluminum, Inconel, Stainless Steel and Steel, Titanium, and Other Materials

Get an online CNC quote.

High Precision Machining Materials

Prototek offers a wide range of top-quality and long-lasting materials perfect for CNC machining. Our materials are made with durability and precision in mind, ensuring that you get the best possible results for your project. We offer an extensive selection, which includes a variety of metals, plastics, and other materials suitable for different types of projects. Whether you need a material that is lightweight and easy to machine or one that is strong and resistant to wear and tear, we have got you covered.

Metal Materials

Aluminum is a durable and lightweight material widely used in various industries, such as aerospace, automotive, and medical. It is known for its precision and flexibility in manufacturing parts that meet specifications. Different industries use aluminum in critical components due to its toughness and longevity.

Brass is commonly used in manufacturing and machining processes due to its durability and excellent mechanical properties, which include corrosion resistance, high tensile strength, and good conductivity. Various applications use brass, such as producing high-precision parts and components for the aerospace and automotive industries or creating decorative and ornamental objects like figurines or sculptures.

Machined bronze is a corrosion-resistant metal used in aerospace, automotive, marine, and medical industries for valve components, bearing housings, bushings, and gears. Our skilled machinists use precision equipment and techniques to shape the material based on design requirements. Bronze is versatile, easy to work with, and available in different shapes and sizes.

Machined copper is a malleable and ductile metal commonly used in industrial applications due to its excellent thermal and electrical conductivity, corrosion resistance, and antimicrobial properties. Polishing, coating, and plating are finishing techniques that improve the appearance and functionality of copper. The electronics, automotive, aerospace, and medical industries use copper for its unique properties and durability.

Nickel-based high-temperature alloys like Inconel, Invar, Kovar, and Nitronic 60 perform excellently in demanding applications. These alloys offer superior corrosion resistance, high-temperature strength, and thermal stability, making them an ideal choice for the aerospace, petrochemical, and power generation industries.

Learn More:

Machined stainless steel is stainless steel that has undergone a machining process. Moreover, stainless steel is popular in manufacturing due to its high strength, corrosion resistance, and aesthetic appeal. However, machining stainless steel can be challenging due to its hardness and rigid properties. Aerospace, automotive, and medical industries use stainless steel with grades 304, 316, and 420. Subsequently, we machine stainless steel components in various sizes and complexity, for use in applications such as surgical instruments, automotive components, and industrial machinery.

Machined steel is a versatile and durable material widely used in various industries. At Prototek Digital Manufacturing, we leverage our expertise in CNC machining to deliver high-quality steel components that meet the most demanding specifications. Our state-of-the-art equipment and skilled technicians ensure precise tolerances, exceptional finishes, and consistent performance, making machined steel a reliable choice for various applications.

Titanium, a strong and lightweight metal, can be shaped and cut using precision machines to create components with unique properties. These components possess exceptional strength, making them ideal for applications where durability is critical. Additionally, titanium has a low density, allowing lightweight machined components without sacrificing strength. It is highly resistant to corrosion and can withstand harsh environments, such as those with high moisture levels, salt, or acid. Surface treatments such as anodizing or passivation can further enhance these properties in titanium components.

Machined tool steel is a strong and durable alloy used in precision operations and cutting machinery in industries such as automotive and aerospace. Additionally, its composition, including tungsten, chromium, and vanadium, enhancing its wear, corrosion resistance, and strength. Engineers use heat treatment processes to increase its hardness and toughness, improving its resilience. Machined Tool Steel manufactures high-quality tools and components from this material.

Plastic Materials

ABS is a lightweight, impact-resistant thermoplastic material with excellent dimensional stability and chemical and abrasion resistance, and it can be machined efficiently and cost-effectively. Various applications use ABS, including automotive parts, toys, furniture, and electronic housing.

Machined acrylic is a lightweight, durable plastic material shaped using computer-controlled machine tools. Various manufacturing applications use acrylic, which is easy to maintain, weather-resistant, and resistant to impact and chemical damage. The high precision and accuracy of machining processes ensure that the final product has smooth edges and precise measurements.

Acetal is a thermoplastic made from POM resin, known for its exceptional mechanical properties and resistance to abrasion, chemicals, and oils. Its low moisture absorption and ease of machining make it ideal for applications such as gears, bearings, bushings, and electrical components in the automotive, aerospace, healthcare, and industrial manufacturing industries.

Machined high-density polyethylene (HDPE) is a durable plastic with excellent moisture, chemical, and weather resistance. Its lightweight nature makes it easy to handle and widely used in various fields, including conveyor components, tanks, machinery parts, food processing equipment, medical devices, and marine components. It is FDA-approved and suitable for use in environments with water. In summary, the machined HDPE is the ideal plastic for those seeking strength, resistance, and versatility.

Nylon is a thermoplastic material with a wide range of applications due to its durability, strength, and lightweight properties. It can be easily machined to produce complex shapes and parts of various sizes and dimensions, making it ideal for multiple industries. CNC machining involves cutting, drilling, and milling nylon to produce high-quality finished products with tight tolerances and accurate specifications. Aerospace, medical, automotive, consumer electronics, and industrial industries use Nylon due to its excellent resistance to impact, chemicals, and wear, making it a perfect choice for demanding environments.

PEEK is a versatile and high-performance polymer with exceptional mechanical and thermal properties. Moreover, it has a high melting point of 550°F (288°C) and is resistant to wear, chemicals, and radiation. Aerospace, automotive, medical, and semiconductor industries use PEEK due to its tight tolerances and accuracy in various shapes and sizes.

Polycarbonate is a highly durable and versatile plastic that has become increasingly popular in various industries. Its clear/translucent composition makes it an ideal material for applications such as medical devices, aircraft windows, and machine parts. Additionally, polycarbonate can be tinted or colored to meet specific requirements, making it a highly adaptable material.

Polypropylene is a highly versatile thermoplastic polymer that finds wide applications in various industries due to its chemical resistance, durability, and ability to perform well in diverse environments. It is highly machinable with high precision, creating parts and products tailored to specific applications. Additionally, the automotive, construction, and medical sectors use polypropylene for its exceptional strength, lightweight construction, and tolerance to high temperatures. Its popularity is increasing due to these impressive attributes.

Teflon/PTFE is a synthetic fluoropolymer known for its unique properties, such as high chemical resistance, low friction, heat resistance, and excellent electrical insulation. When CNC is machined, it is often used in various applications, including aerospace, medical devices, industrial equipment, and more. Its versatility and durability make it a popular choice for applications that require precision and reliability.

Ultem is a highly reliable material used in various industries, such as automotive, medical, and aerospace. It offers excellent strength, durability, and unparalleled mechanical and dimensional stability. With CNC machining, Ultem components can be produced with great precision and reproducibility, making it ideal for small and large-scale manufacturing operations. Ultem components are known for their high-quality standards, toughness, and resilience to harsh environmental conditions such as high temperatures, chemicals, and flame resistance.

CNC Machining Finishes

Proper finishing is crucial for CNC machine shop projects to ensure that the CNC machined parts are functional, aesthetically pleasing, and defects-free. Our CNC machine shop provides a range of surface finishes, including sandblasting, powder coating, anodizing, graining, electroplating, painting, and polishing. Choosing the appropriate finish for the material and application is essential, and working with an experienced CNC machining online service provider is necessary for quality assurance. If you have any questions regarding our CNC machine shop finishes, please don’t hesitate to contact us.

Why should you choose Prototek's online machining service for your next project?

Do you need a reliable online machining service for your upcoming project? Look no further than Prototek. Our team of experts is dedicated to delivering precise parts with a quick turnaround time, all while offering competitive pricing. Moreover, our state-of-the-art equipment and software can produce parts with unparalleled accuracy and consistency. Our user-friendly online platform lets you quickly request quotes, upload designs, and track your orders in real-time. Furthermore, you’ll have access to various materials and finishing options to meet your project requirements. Therefore, select Prototek for a seamless and efficient machining experience.