The History of Nylon Material for Manufacturing

Nylon, a synthetic polymer introduced in the 1930s, has become crucial to modern manufacturing. This groundbreaking material has played a pivotal role in shaping the products we use daily, from clothing and textiles to automotive parts and industrial components.

Tracing the origins can lead back to the research efforts of Wallace Hume Carothers, a chemist working for DuPont. In 1935, Carothers and his team successfully synthesized the first nylon polymer, marking a significant milestone in the history of materials science.

Initially, nylon’s primary purpose was stocking production, but it quickly became a popular and affordable alternative to silk. Nylon’s versatility soon became apparent as manufacturers recognized its potential for various applications.

During World War II, its exceptional strength and durability made it an invaluable material for producing parachutes, ropes, and other military equipment. This wartime demand accelerated the development and refinement of nylon-based manufacturing processes, paving the way for its widespread adoption in the post-war era.

In the following decades, nylon’s versatility continued to drive innovation across various industries, from the automotive sector, where components such as gears and bearings use this material, to the construction industry, where the use of nylon in reinforced concrete and insulation materials, nylon has proven to be a game-changer.

Today, nylon remains a staple in the manufacturing landscape. Furthermore, ongoing advancements in polymer science and processing techniques are further expanding its applications. As the world continues to demand more efficient, durable, and sustainable products, the legacy of this material’s pioneering role in the industry remains a testament to the power of innovation and the transformative potential of materials science.

Different Types of Nylon Materials for Manufacturing

Nylon 6

Nylon 6, or PA 6, is known for its excellent abrasion resistance, and an everyday use of this material is the manufacture of automotive parts, gears, bearings, and industrial machinery components. Synthesizing it from the organic compound caprolactam consists of repeating rings of six carbon atoms. PA 6 exhibits high tensile strength, toughness, and elasticity. However, it absorbs moisture, affecting its dimensional stability and mechanical properties. It melts at around 428°F (220°C) and is resistant to many chemicals, oils, and solvents.

Additionally, it is self-lubricating and offers abrasion resistance. Nylon 6 finds applications in gears, bushings, and automobile components like intake manifolds and engine covers. Because of its electrical properties, it can also be found in insulators and connectors. Our machine shops keep this material in stock as it is suitable for milling and other CNC machining and fabrication types.

Nylon 66

Nylon 66, or PA 66, is regular in engineering applications because of its excellent heat resistance and mechanical properties. A few typical applications are electrical connectors, fasteners, and high-performance components. Two monomers – adipic acid and hexamethylenediamine- contribute to rings of six carbon atoms, creating PA 66. The repeating rings in its structure enhance tensile strength, toughness, and durability while decreasing moisture absorption. It has a melting point of around 500°F (260°C) and is more robust than other types of nylon, with about a 20% increase in strength. Two standard CNC machining and fabricating grades are natural and glass-filled.

Nylon 6/12

Nylon 6/12, or PA 6/12, is a polyamide consisting of alternating molecules of hexamethylenediamine (containing six carbon atoms) and dodecanedioic acid (containing 12 carbon atoms). Comparing PA 6 or PA 66, to PA 6/12 is slightly less rigid but has a melting point between the two. Additionally, it has a lower tendency to absorb moisture. Due to its outstanding mechanical properties and resistance to heat, oil, and chemicals in the automotive and industrial sectors, this versatile material finds applications in various areas, such as gears, bearings, bushings, and other under-the-hood components. It can also manufacture household items, sports equipment, and other consumer products that withstand everyday wear and tear. Due to its properties, Utilizing nylon 6/12 is common in injection molding to create various plastic components.

Nylon 11

Nylon 11, or PA 11, is known for its flexibility, chemical resistance, low moisture absorption, strength, impact resistance, and ability to maintain dimensional stability in humid conditions. The synthesis of PA 11 from 11-aminoundecanoic acid, a monomer derived from castor oil, with each repeating link of PA 11’s polymer chains, contains 11 carbon atoms with a lower melting point of 410°F (210°C). Various industries use this material, including automotive, sports, and consumer goods, and in applications such as enclosures and housing.

Fire-retardant PA 11 is available at Prototek in our 3D printing facilities that use selective laser sintering (SLS) technologies. This Nylon 11 has high strength, impact resistance, rigidity, and wear and tear resistance properties.

Nylon 12

Nylon 12, or PA 12, is known for its flexibility and chemical resistance to various substances such as chemicals, salts, and oils. It has lower moisture absorption and a lower melting point of about 356°F (180°C). This material is a linear aliphatic polyamide, meaning its structure consists of open chains of carbon atoms (12 in this case) rather than rings. The automotive, sports, and consumer goods industries use PA 12 for enclosures, fixtures, fuel systems, and electrical connectors.

What manufacturing capabilities work with nylon?

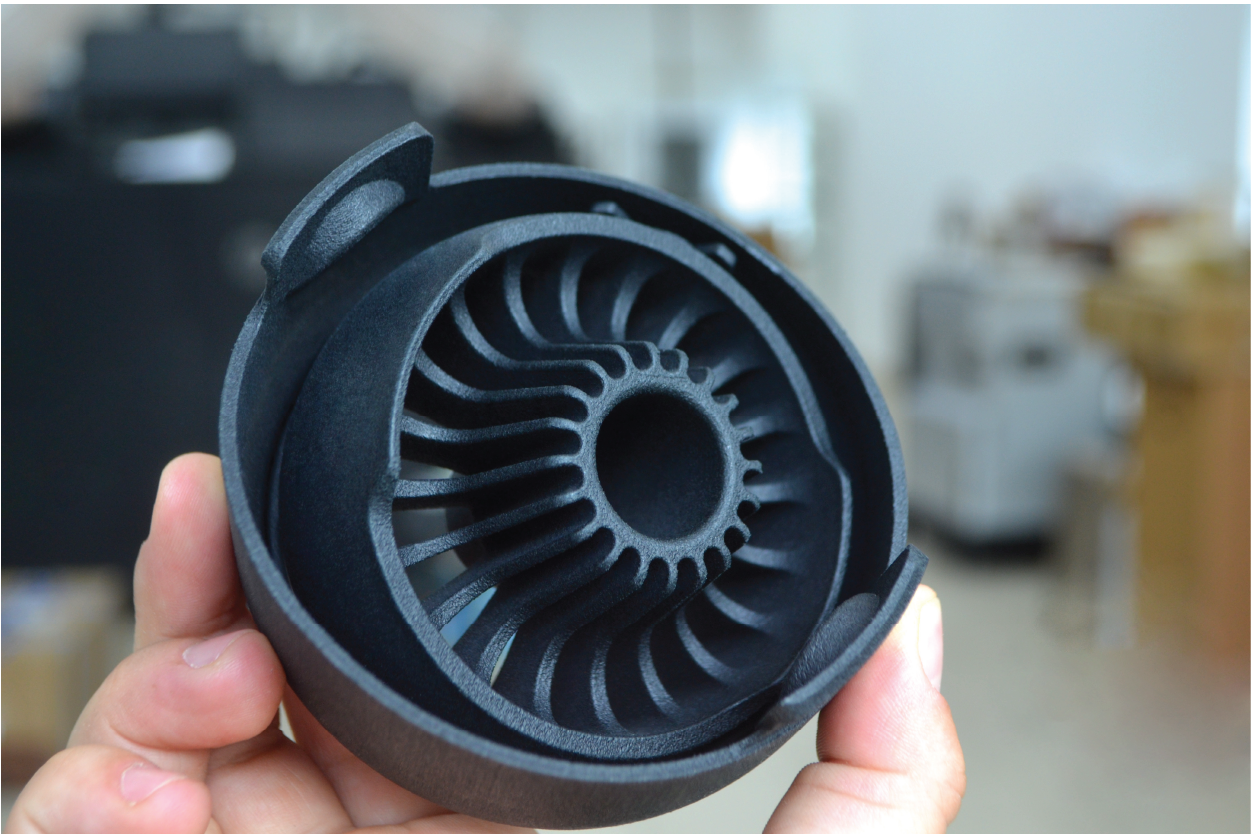

Additive Manufacturing

Nylon is a highly versatile material with extensive application in additive manufacturing processes like selective laser sintering (SLS) and multi-jet fusion (MJF). In SLS, the machine selectively fuses the PA powder using a high-powered laser, creating solid and durable parts. MJF, on the other hand, employs a fusing agent and infrared heating to bind the particles, resulting in parts with fantastic mechanical properties and surface finish. Given its inherent strength, flexibility, and heat resistance, nylon is an ideal choice for various applications in industries such as automotive, aerospace, and consumer goods.

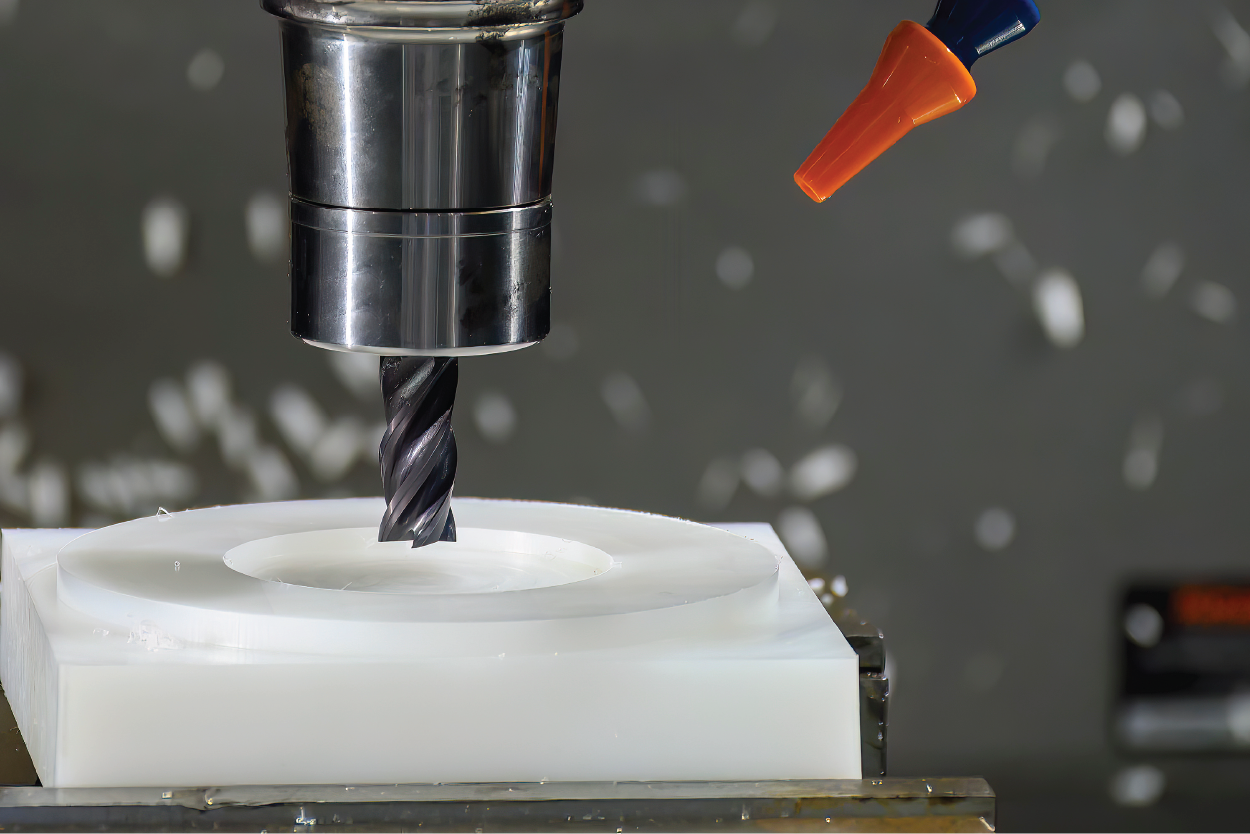

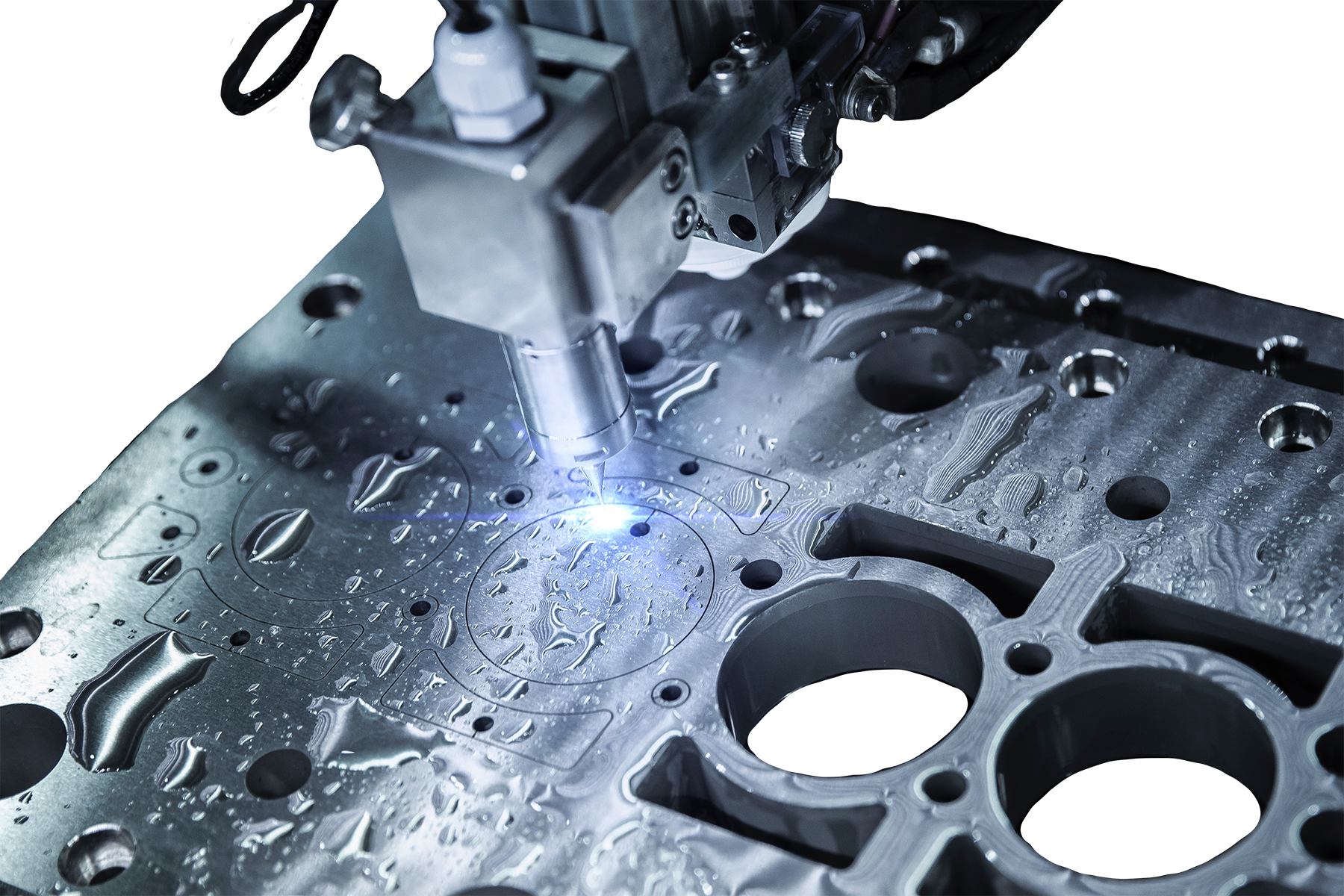

CNC Machining

Nylon is a versatile thermoplastic material for CNC machining applications. This material’s excellent mechanical properties, such as high strength, stiffness, and wear resistance, make it an ideal choice for producing various components and parts. Furthermore, in CNC machining, nylon can be precisely machined into complex shapes and geometries, creating intricate and intricate parts. Moreover, its low coefficient of friction and self-lubricating properties make it suitable for manufacturing moving parts and components that require smooth operation and reduced wear. Overall, using nylon in CNC machining enables the production of high-quality, durable, and reliable parts across a wide range of industries.

Fabricated Sheets

Nylon is a versatile thermoplastic material commonly fabricated from sheets using laser and waterjet cutting machines for various applications. PA sheets offer excellent mechanical properties, including high strength, stiffness, and impact resistance. They are lightweight, durable, and corrosion-resistant, making them suitable for various manufacturing, construction, and transportation industries. The sheets can be easily formed and fabricated into complex shapes, allowing for the creation of custom parts and components. Additionally, nylon’s inherent chemical and thermal resistance make it an ideal choice for applications that require exposure to harsh environments or high temperatures.

Silicone & Urethane Casting

Urethane casting uses this highly versatile material for its strength, durability, and dimensional stability. These properties make it an ideal choice for creating molds and patterns. In using urethane casting, as a core material or reinforcement to improve the structural integrity of the final cast part. Additionally, the smooth surface finish of nylon aids in producing high-quality, elaborate castings.

Injection Molding

Injection molding uses this versatile thermoplastic material in a wide range of applications. Its excellent mechanical properties, including high strength, stiffness, and impact resistance, make it an ideal choice for various products and industries. In injection molding, PA is melted and injected into a mold cavity, which cools and solidifies, taking the shape of the desired part. This material’s ability to flow easily during the injection process and its dimensional stability after cooling makes it popular for producing complex, intricate parts with tight tolerances. From automotive components to consumer goods, nylon injection molding offers a cost-effective and efficient manufacturing solution.

How do you choose the most suitable nylon material for your manufacturing project?

Consider several key factors when selecting the most suitable nylon material for your manufacturing project. Evaluate the specific performance requirements, such as strength, flexibility, heat resistance, and chemical compatibility. Also, assess the manufacturing process, part geometry, and production volume to determine the optimal grade and form of PA. Our team of engineering experts can guide you to help you identify the nylon material that will deliver the best results for your unique application. If you have questions, don’t hesitate to reach out!

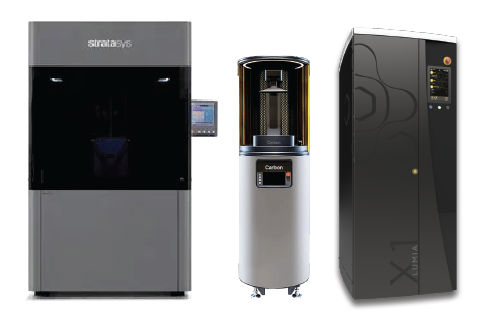

Additive Manufacturing Services

Discover the power of cutting-edge additive manufacturing technologies with Prototek. Our highly skilled team is ready to transform your groundbreaking ideas into reality, offering services ranging from rapid prototyping to small-scale production on a variety of technologies.

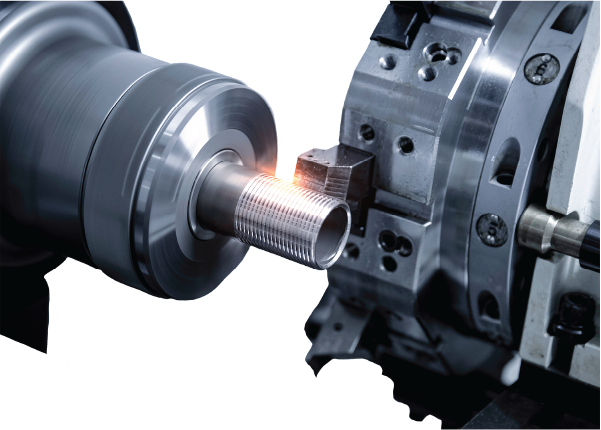

CNC Machine Shop Services

Prototek offers state-of-the-art CNC machining services to meet your precise manufacturing needs. Our skilled technicians utilize the latest CNC technology to deliver high-quality components with unparalleled precision and efficiency—Trust Prototek for all your CNC machining requirements.

Sheet Metal Fabrication Services

At Prototek, we offer comprehensive sheet metal fabrication services to meet your manufacturing needs. Our skilled team utilizes the latest technology and techniques to deliver high-quality, precision-engineered components. From prototyping to production, trust Prototek to bring your ideas to life.

FAQs

It is a versatile synthetic polymer widely used in manufacturing. This material is known for its strength, durability, and resistance to wear and tear.

Components can be finished with a variety of techniques, including tumbling, bead blasting, and electroplating to enhance their appearance and durability.

Nylon 6, Nylon 66, and Nylon 12 are a few of the most common nylon grades used in manufacturing. These grades offer varying levels of strength, flexibility, and chemical resistance.