Bead blasting cleans, polishes, or removes dirt from metal, plastic, ceramic, and glass. In this process, ceramic or metal beads are shot at high speed using compressed air or a spinning wheel. Striking the material’s surface creates a textured finish, which can improve the material’s look, strength, and durability.

Bead blasting is a versatile and standard post-processing technique in the automotive, aerospace, construction, and manufacturing industries. It is adept at preparing parts for painting or coating, removing rust or corrosion from metal surfaces, and creating a matte or satin finish on polished metals. Its adaptability makes it a valuable tool across various industries.

Bead blasting is a versatile and standard post-processing technique in the automotive, aerospace, construction, and manufacturing industries. It is adept at preparing parts for painting or coating, removing rust or corrosion from metal surfaces, and creating a matte or satin finish on polished metals. Its adaptability makes it a valuable tool across various industries.

Additive Manufacturing, CNC Machining, Sheet Metal Fabrication, Urethane Casting, and Injection Molding.

Glass Beads, Ceramic Beads, Metal Beads, Sand, Shot

Aesthetics, Cleaning, Deburring, Paint & Coating Preparation

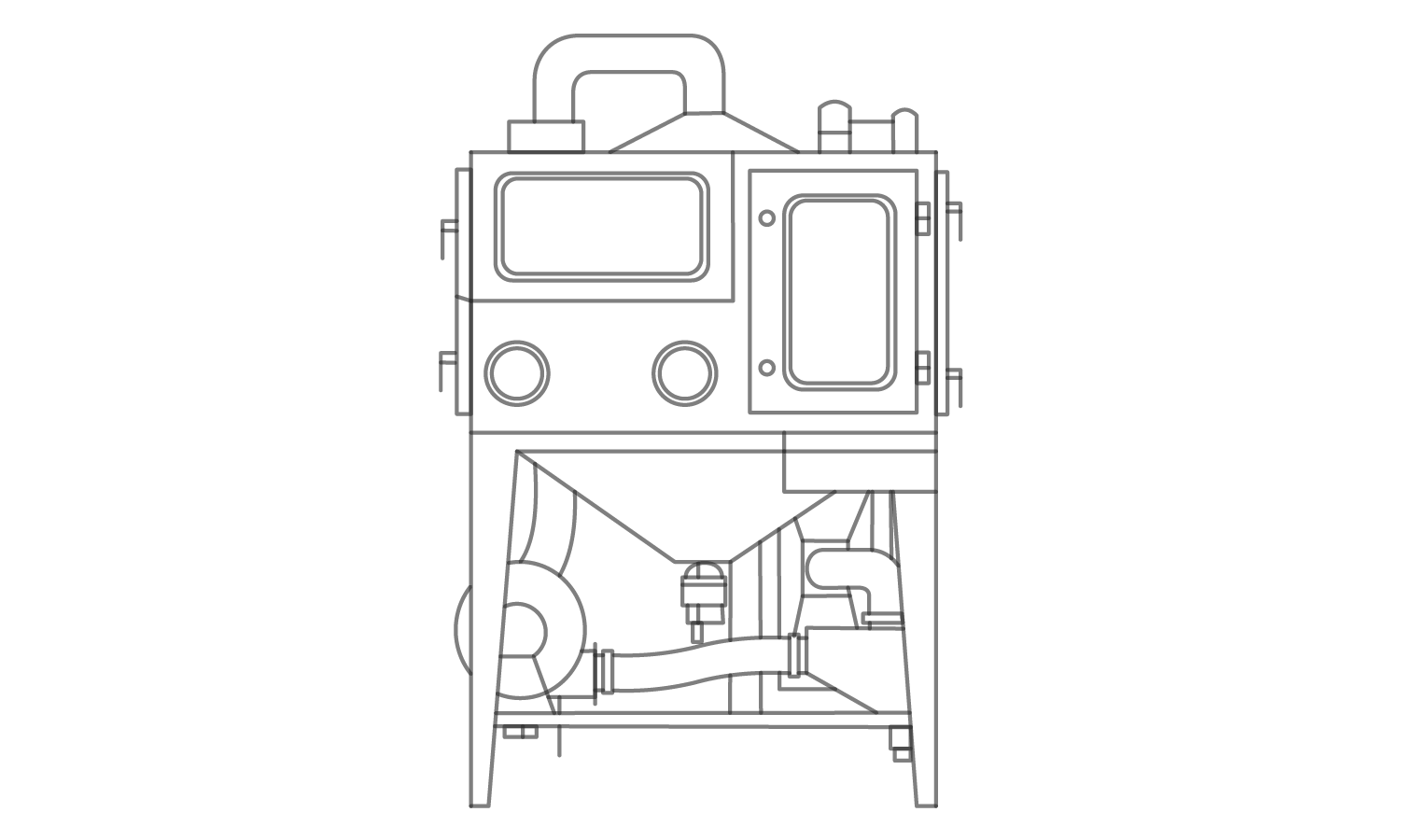

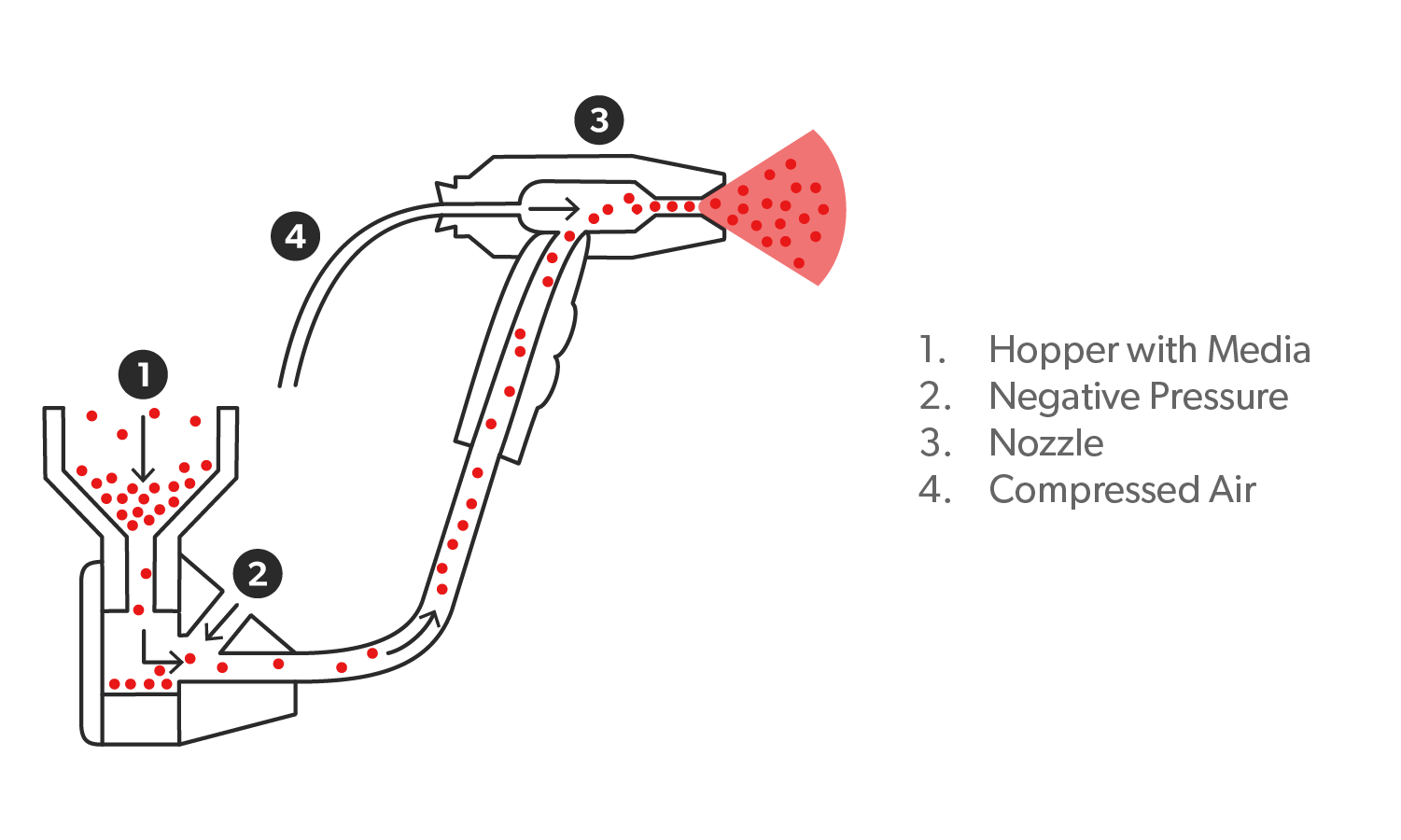

Bead blasting is a process used to clean and finish 3D-printed parts. It works by shooting small beads or particles at high speeds onto the surface of a part. Helping to remove rough areas and any leftover material from the printing process. A bead blasting machine uses compressed air to propel the beads.

The bead blasting process is gentle and does not damage the 3D-printed part. Many industries use this method, such as aerospace, automotive, and medical device manufacturing. Bead blasting effectively ensures that 3D-printed parts are smooth, debris-free, and have a consistent finish.

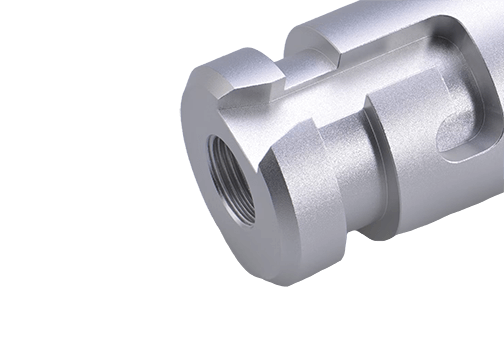

Bead blasting is a method for cleaning and smoothing metal objects. It involves shooting tiny beads made of glass, ceramic, or metal at high speed onto the object’s surface. This process helps remove dirt and change the texture of the metal.

First, the metal object is placed in a sealed chamber to contain the beads. A high-pressure air hose then spreads the beads inside the chamber, hitting the object’s surface to eliminate impurities. The beads are chosen depending on the material and the desired finish. For instance, glass beads are standard for delicate surfaces, ceramic beads for metal surfaces, and metal beads for tough stains. After the blasting, the beads are recycled and reused, making the process cost-effective and environmentally friendly.

The final result is a clean, smooth, and even surface perfect for painting or electroplating.

Bead blasting is a valuable and efficient way to clean and finish surfaces. It involves shooting tiny glass beads or abrasive particles onto a surface to remove dirt, rust, or old paint. This method produces a smooth finish without scratches, making it great for preparing surfaces for painting or coatings. You can use bead blasting on different materials, including metals, plastics, and delicate items, without causing damage. It is a cost-effective and time-saving option for manufacturing projects that need thorough cleaning and surface preparation.

AS9100D | ISO 9001 | ITAR Registered

Casting & Molding

Added Value

Connect with us: