We are thrilled to delve into the world of nickel plating for additive manufactured, CNC machined, and sheet metal fabricated parts. Join us as we explore this versatile finishing method’s fundamentals, benefits, applications, and best practices. Whether you aim to boost corrosion resistance, enhance appearance, or tap into new design opportunities, nickel plating can revolutionize your projects.

What is nickel plating?

Nickel plating is a widely used metal finishing process that involves depositing a thin layer of nickel onto the surface of another metal or plastic, such as ABS, brass, copper, nylon, polyamide, or steel. The process offers several advantages, including improved corrosion resistance, enhanced appearance, and increased durability.

Furthermore, the nickel plating process works by electrochemically bonding the nickel to the underlying substrate, creating a protective barrier that shields the base material from environmental factors such as moisture, chemicals, and abrasion. This results in a smooth, lustrous, functional, and aesthetically pleasing finish.

Moreover, this finish is known for its exceptional corrosion resistance. It acts as a barrier to prevent the base metal from reacting with the surroundings and developing rust or tarnish, making it an ideal choice for applications in harsh environments, such as the automotive, marine, and industrial equipment industries.

In addition to its protective properties, nickel plating enhances the appearance of the finished product, adding a touch of elegance and sophistication to a wide range of products, from decorative hardware to electronic components.

How is it done?

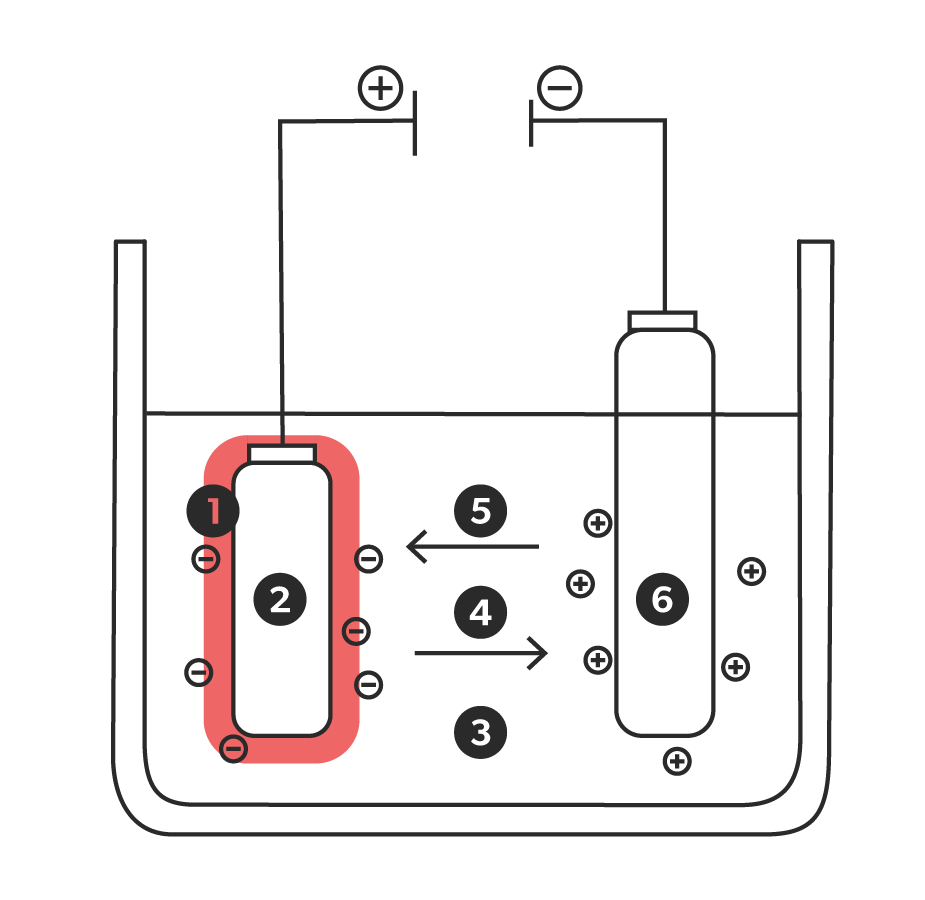

Nickel plating, also known as nickel electroplating, is an electrochemical process. In short, the process involves transferring an electric current to attract and deposit metal ions suspended in an electrolytic solution onto a surface. The plating process involves several steps:

1. Cleaning Parts: This critical step involves meticulously removing debris and contaminants from the surfaces of the components. It is essential to ensure the proper adhesion and strength of the plated deposit, so your attention to detail in this process is crucial for the success of the overall plating process.

2. Rinsing: After each step in the plating process, it’s crucial to rinse the component thoroughly to maintain the purity of the process. This step is not just a requirement but a necessity, as it removes all contaminants and chemical residue from the parts. Additionally, your vigilance in using de-ionized water for rinsing is instrumental in upholding the integrity of the process.

3. Testing for Cleanliness: This step thoroughly removes all surface contamination. Typical tests include water break-free testing and surface cleanliness verification meters.

4. Nickel Plating Bath One: This initial step of immersing parts in a chemical tank filled with a positively charged nickel electrolytic salt solution. Subsequently, once the parts are connected to the negative terminal of a rectifier, the electrochemical process begins. Additionally, an anode in the tank acts as the source of nickel metal, replenishing nickel ions in the solution. A direct current passes through the solution, causing the positively charged nickel ions to be attracted to the negatively charged components, depositing them onto the surface.

5. Nickel Plating Bath Two: Parts sometimes require two types of plated deposits, so they must be submerged in a secondary plating bath. The initial layer is often called an underplate or strike, whereas the subsequent layer is the top plate.

6. Final Rinse: The parts go through a series of rinses, with subsequent rinses designed to remove any remaining contaminants. The final rinse is heated to minimize staining on the plated parts.

7. Drying: The parts can be either baked in an oven or dried with forced air to ensure the absence of any water residue.

Throughout the plating process, various parameters such as pH, bath flow rate, nickel ion concentration, temperature, current density, and voltage from the rectifier are closely monitored and controlled. Maintaining these parameters within the desired range is crucial for achieving results.

Image

- Nickel Plating

- Anode

- Nickel Solution

- Cations

- Anions

- Cathode

What are the benefits for nickel plating?

The nickel plating process enhances corrosion and wear resistance in metal and plastic components, making it well-suited for the automotive, aerospace, consumer products, electronics, industrial, and healthcare sectors. Additionally, we offer reliable advanced finishing services tailored to your requirements, whether for prototypes or production runs.

Additive Manufactured

Nickel plating is a versatile surface treatment that offers numerous benefits for additive manufactured parts and components. It provides enhanced corrosion resistance, improved wear and abrasion properties, and a decorative finish that can elevate the appearance of your products. Moreover, this advanced finish is well-suited for parts exposed to harsh environments, as it creates a durable barrier against oxidation and chemical attack. Additionally, the plating process can help to improve the dimensional accuracy and surface finish of 3D printed parts, making them more suitable for critical applications.

CNC Machining

Nickel plating offers various benefits for CNC-machined parts and components. It provides a durable, corrosion-resistant finish that protects against wear, abrasion, and harsh environmental conditions. Moreover, it enhances the appearance of parts with a lustrous, uniform metallic finish. Additionally, it improves electrical and thermal conductivity, making nickel-plated components ideal for various industrial and commercial applications. With its exceptional performance characteristics, nickel plating is a trusted solution for enhancing the longevity and reliability of CNC-machined parts and components.

Sheet Metal Fabrication

Nickel plating offers numerous benefits for sheet metal fabrication parts and components. First and foremost, it provides excellent corrosion resistance, enhancing your products’ durability and lifespan. In addition, the shiny finish also enhances the aesthetic appeal, making your parts stand out. Moreover, nickel plating is highly resistant to wear and tear, ensuring that your components maintain their integrity even in demanding applications. Additionally, the plating process can improve the underlying metal’s hardness and abrasion resistance, further extending the useful life of your sheet metal fabrications.

Applications for Nickel Plating by Industry

Nickel plating is a versatile surface finishing technique for additive manufacturing, CNC machining, and sheet metal fabrication with various applications across various industries. From automotive components to electronics, it provides superior corrosion resistance, enhanced durability, and an attractive aesthetic finish. Our state-of-the-art capabilities at Prototek Digital Manufacturing can help you achieve your products’ desired performance and appearance.

The following are typical applications of nickel plating in the respective industries.

Aerospace & Defense

- Fasteners

- Landing Gear Components

- Structural Components

- Turbine Blades

Automotive

- Decorative Accents

- Fasteners

- Hardware

- Internal and External Trim

Consumer Products

- Appliances & Electronics Housings

- Cookware & Utensils

- Door Knobs & Hinges

- Faucets & Other Bathroom Fixtures

- Jewelry & Watches

Electronics & Semiconductors

- Circuitboards

- Computer Parts

- Connector Pins

- Smart Phone Components

- Switch Contacts

Energy & Industrial

- Connectors

- Fasteners

- Fittings

- Switches

- Valves

Medical & Dental

- Dental Tools

- Fixtures

- Medical Equipment

- Orthopedic Implants

- Surgical Instruments

Why choose nickel plating for your project?

Nickel plating offers many benefits, making it an excellent choice for manufacturing projects. Firstly, it provides superior corrosion resistance, enhancing the durability and lifespan of your components. Additionally, the lustrous, uniform finish delivers an attractive aesthetic that can elevate the appearance of your products. Moreover, nickel is a wear-resistant matting ideal for enhanced surface protection applications. With Prototek’s expertise in nickel plating, you can trust that your parts will receive a high-quality finish that meets your exact specifications.

Are you ready to start your project?

FAQs

It is a popular metal finishing process that provides a durable, corrosion-resistant, and decorative coating on various metal surfaces. It enhances the appearance and protects the underlying material from wear and tear.

We offer this advanced finish for different plastic and metal materials, including ABS, nylon, aluminum, and stainless steel for our additive manufacturing, cnc machining, and sheet metal fabrication services.

Absolutely! Aluminum can be nickel-plated to enhance its corrosion resistance, hardness, and aesthetic appeal. The process involves depositing a thin nickel layer onto the aluminum surface, creating a durable and long-lasting finish. This combination of materials is commonly used in various industrial applications, from automotive components to aerospace parts, where strength and corrosion protection are crucial.

This finish can be cleaned by gently wiping with a soft cloth, mild soap, and water solution. Avoid abrasive cleaners or scrubbing, as this can damage the plating. For stricter buildup, use a diluted vinegar or lemon juice solution.

It can be polished using a soft cloth and a mild metal polish. Gently rub the surface to remove any tarnish or discoloration, revealing a shiny finish.

It has a distinctive silvery-white luster. Look for an even, shiny finish to check if a component is nickel-plated. Nickel is also non-magnetic, so a magnet test can help identify it.