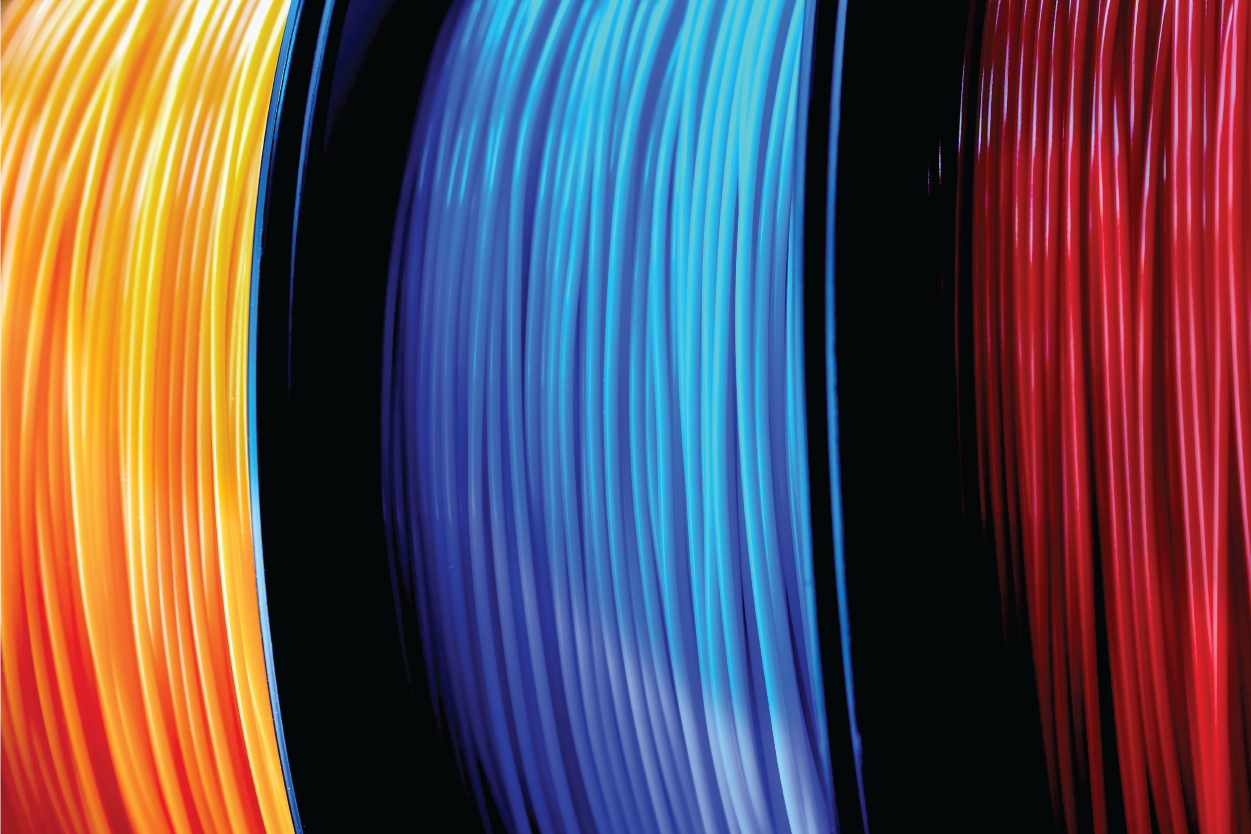

Acrylonitrile Butadiene Styrene (ABS) is a flexible plastic used in making products and designs. This blog post will examine ABS, focusing on its main features, different uses, and why it is a great choice for many industries.

What is the history of acrylonitrile butadiene styrene, and how is it made?

Acrylonitrile butadiene styrene, or ABS, is an essential plastic type in our daily lives. Its unique properties and long development history allow for many uses, from Lego bricks to car parts.

Researchers in Germany first made ABS in the 1930s. Initially, the automotive industry used it because it is strong and durable, making it perfect for different car parts.

Over the years, the way we make ABS has improved. This change has allowed manufacturers to control their properties better and expand their uses. Today, making ABS involves combining acrylonitrile, styrene, and butadiene to create a strong, lightweight, and impact-resistant material. This versatility makes it popular in many industries.

ABS has many advantages. It resists chemicals, heat, and impact and is easy to mold, making it an excellent choice for various applications, such as household appliances, electronics, toys, and car parts.

As technology progresses, the ABS manufacturing process continues to improve, focusing on better performance and sustainability. At Prototek Digital Manufacturing, we offer a range of ABS manufacturing services, including additive manufacturing, CNC machining, and sheet metal fabrication, to help our clients bring their ideas to life.

What are the mechanical properties of acrylonitrile butadiene styrene?

Acrylonitrile butadiene styrene (ABS) is a strong plastic used in many products because of its rugged and durable nature. It is primarily known for its ability to resist impact, which makes it ideal for items that need to withstand force.

ABS also has excellent tensile strength, meaning it is tear-resistant, and flexural strength, which allows it to handle bending without breaking. These traits help ABS stay strong and maintain its shape under different stresses.

This material is stable in size and shape, even when temperatures or humidity change. This stability is essential for manufacturing, where accuracy is required.

Additionally, ABS can tolerate high temperatures without losing its strength or shape. Standard methods for making ABS include machining, molding, and extrusion, allowing various production techniques.

Due to its versatility and performance, ABS is a popular choice in many areas, such as automotive parts, consumer products, electronics casings, and 3D printing.

Which industries use the ABS?

ABS (Acrylonitrile Butadiene Styrene) is a flexible plastic used in many industries. Some key sectors that use ABS include:

Automotive

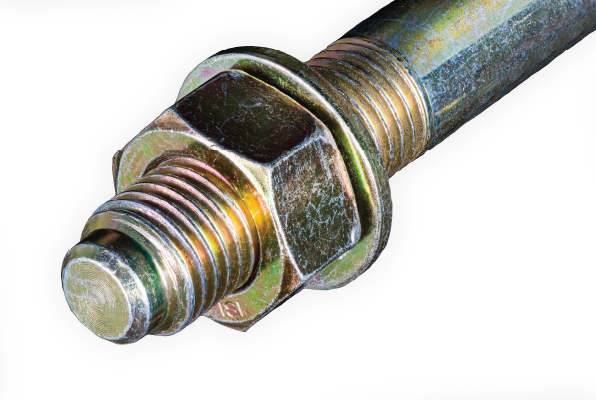

ABS is a strong and durable plastic commonly used to make car parts. It is easy to mold, making it ideal for items like dashboards, door panels, bumpers, and interior trim.

Electronics

ABS is a common material for covering electronic devices like computers, phones, and home appliances. It is popular because it insulates well and resists heat and chemicals.

Consumer Products

Manufacturers make consumer products like toys, sports equipment, and household items from ABS. They chose ABS because it is strong, resistant to impact, and looks good.

Construction

Due to its weather resistance and long-lasting performance, the construction industry uses ABS for piping, window frames, and electrical conduits.

Medical

The medical industry employs ABS to produce medical devices, prosthetics, and housing equipment, taking advantage of its biocompatibility and sterilization capabilities.

What are the benefits of using acrylonitrile butadiene styrene for your project?

Acrylonitrile butadiene styrene (ABS) is a strong and durable plastic material that is useful for many projects. It is known for its ability to resist impact, making it a good choice for items that need to be tough. ABS also keeps its shape well, keeping your parts accurate even when conditions change. It is easy to machine and can be injection molded, which helps create complex shapes and detailed designs. With many colors available, ABS can fit the look you want for your project. ABS is a dependable and affordable material that can help you reach your manufacturing goals.

Are you ready to start your project?

FAQs

Acrylonitrile Butadiene Styrene is a durable and versatile thermoplastic material in 3D printing, machining, and fabrication.

Due to its durability and versatility, the automotive, consumer electronics, and construction industries use ABS.

Automotive parts, consumer electronics, household items, and toys use ABS. This versatile material is prized for its strength, durability, and impact resistance, making it an ideal choice for manufacturers across multiple industries.

There are a variety of options for finishing ABS to enhance its appearance and durability, including, but not limited to, painting, which provides a colorful design; plating, which adds a layer of metal for a sleek look; and polishing, which creates a smooth, glossy surface that enhances the overall finish and quality of the product.