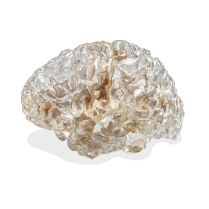

Biocompatible

Biocompatible additive manufacturing materials are a critical component in the medical industry. These materials create devices, implants, and surgical instruments that interact with the human body, so their characteristics are essential. The properties of biocompatible materials include biocompatibility, stabilizability, and durability. They should be inert, non-toxic, and not cause adverse tissue reactions. Biocompatible materials should also have the necessary mechanical strength to withstand the rigors of use in the body. Additive manufacturing techniques have enabled the creation of complex geometries that are impossible with traditional manufacturing methods. To meet these requirements, biocompatible additive manufacturing materials are continuously improving, providing the ability to design and produce custom products that meet patient-specific requirements with high precision.

Special processing may be required. Please notify us of any biocompatibility needs.

Showing all 16 results

-

Accura® AMX Rigid Black for SLA

Read more -

Accura® AMX Tough FR V0 Black for SLA

Read more -

Accura® ClearVue for SLA

Read more -

EPU 40 | Elastomeric Polyurethane

Read more -

EPU 41 | Elastomeric Polyurethane

Read more -

EPU 46

Read more -

HP Nylon 12 for MJF

Read more -

HP Nylon 12 GB for MJF

Read more -

MPU 100 | Medical Polyurethane

Read more -

Nylon 12 for SLS

Read more -

PC-ISO

Read more -

RPU 70 | Rigid Polyurethane

Read more -

SIL 30 | Silicone

Read more -

Somos® BioClear

Read more -

ULTEM 1010

Read more -

UMA 90 | Urethane Methacrylate

Read more