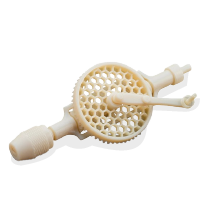

Rigid

In additive manufacturing, using materials with rigid properties can prove to be quite advantageous. Such materials are often used with additive-manufactured components to enhance their structural integrity and performance. The materials’ rigidity helps impart strength and stability to the final product, making it more durable and deformation-resistant. Additionally, using rigid materials can reduce the risk of cracking or warping during printing, resulting in a more precise and accurate final product. Overall, incorporating rigid materials into additive manufacturing processes can significantly improve the end product’s quality, reliability, and longevity.

Showing all 33 results

-

Accura® 60 for SLA

Read more -

Accura® ABS Black for SLA

Read more -

Accura® AMX Rigid Black for SLA

Read more -

Accura® AMX Tough FR V0 Black for SLA

Read more -

Accura® SL 5530 for SLA

Read more -

Accura® Xtreme

Read more -

Accura® Xtreme White 200

Read more -

Digital ABS Plus

Read more -

EPX 82 | Epoxy

Read more -

EPX 86FR | Flame Retardant Epoxy

Read more -

Fire Retardant Nylon 11 for SLS

Read more -

Glass Filled Nylon 12 for SLS

Read more -

HP Nylon 12 GB for MJF

Read more -

Loctite3D IND405 Clear

Read more -

Nylon 12 for SLS

Read more -

Nylon 12CF

Read more -

PA 602-CF

Read more -

RPU 130 | Rigid Polyurethane

Read more -

RPU 70 | Rigid Polyurethane

Read more -

Somos® PerFORM

Read more -

Somos® WaterClear Ultra 10122

Read more -

Somos® WaterShed Black

Read more -

Somos® WaterShed XC 11122

Read more -

ULTEM 9085

Read more -

Ultracur3D 3280

Read more -

UMA 90 | Urethane Methacrylate

Read more -

Vero Clear

Read more -

VeroBlackPlus

Read more -

VeroCyan

Read more -

VeroGrey

Read more -

VeroMagenta

Read more -

VeroWhitePlus

Read more -

VeroYellow

Read more