Comprehensive CNC Machining Guide

Unlock the power of CNC Machining to grow your business through innovation to scale with this guide.

This CNC Machining Guide provides an overview of Prototek’s capabilities. CNC machining is a popular method for both manufacturing and prototyping parts. However, it’s essential to understand the basics of CNC machining and consider some best practices when designing your product to ensure it can be produced quickly and cost-effectively. We have compiled some information and recommendations to help you remember these best practices while developing your product.

If you have more questions, contact a Prototek Solutions Manager.

Introduction to CNC Machining

In this part of the Machining Guide, we’ll cover:

A short History of CNC machining.

What is CNC machining?

What types of machines are there?

CNC Machining Materials

Common Materials:

Metals

Plastics

Other Material

Design Guide: CNC Machining

Recommendations for cavities and pockets, engraving, holes, internal edges, and more.

CNC Machining Finishes

Explore our range of finishes and discover the benefits each offers. Choose the perfect finish for your project.

Introduction to CNC Machining

This design guide for CNC machining will share a few tips and tricks, but first, we’ll give a tiny history lesson—just in case you like trivia or history. The CNC machine was first developed in 1949 by James Parsons, a computer engineer on a research project for the Air Force. While figuring out how to produce airplane and helicopter parts, he was able to calculate helicopter airfoil coordinates with an IBM 602A multiplier and fed the data into a punched card. He then used it on a Swiss jig borer. Using this method, he produced many helicopter blades and other aircraft parts.

From there, the evolution of CNC (Computer Numerical Control) machines takes a remarkable journey. Initially, operators controlled CNC machines using a punch card system, but with technological advancement, they are now software-powered. CNC machines are unique because they are programmed to cut, shape, and drill various materials, including metal, wood, and plastic.

One significant advantage of CNC machining is its accuracy. Unlike older NC (Numerical Control) machines, CNC machines can produce precise and accurate parts. CNC machines use a computer program to guide the cutting tools, ensuring the cuts are consistent and precise, making it easy to produce complex shapes and parts.

Another advantage of CNC machines is their speed. They can perform complex cutting operations in a fraction of a manual machine operator’s time, producing more parts in less time, making them ideal for mass production.

The evolution of CNC machines has revolutionized the manufacturing world. These machines are faster, more accurate, and more precise than their predecessors, allowing manufacturers to produce complex parts and products quickly and efficiently.

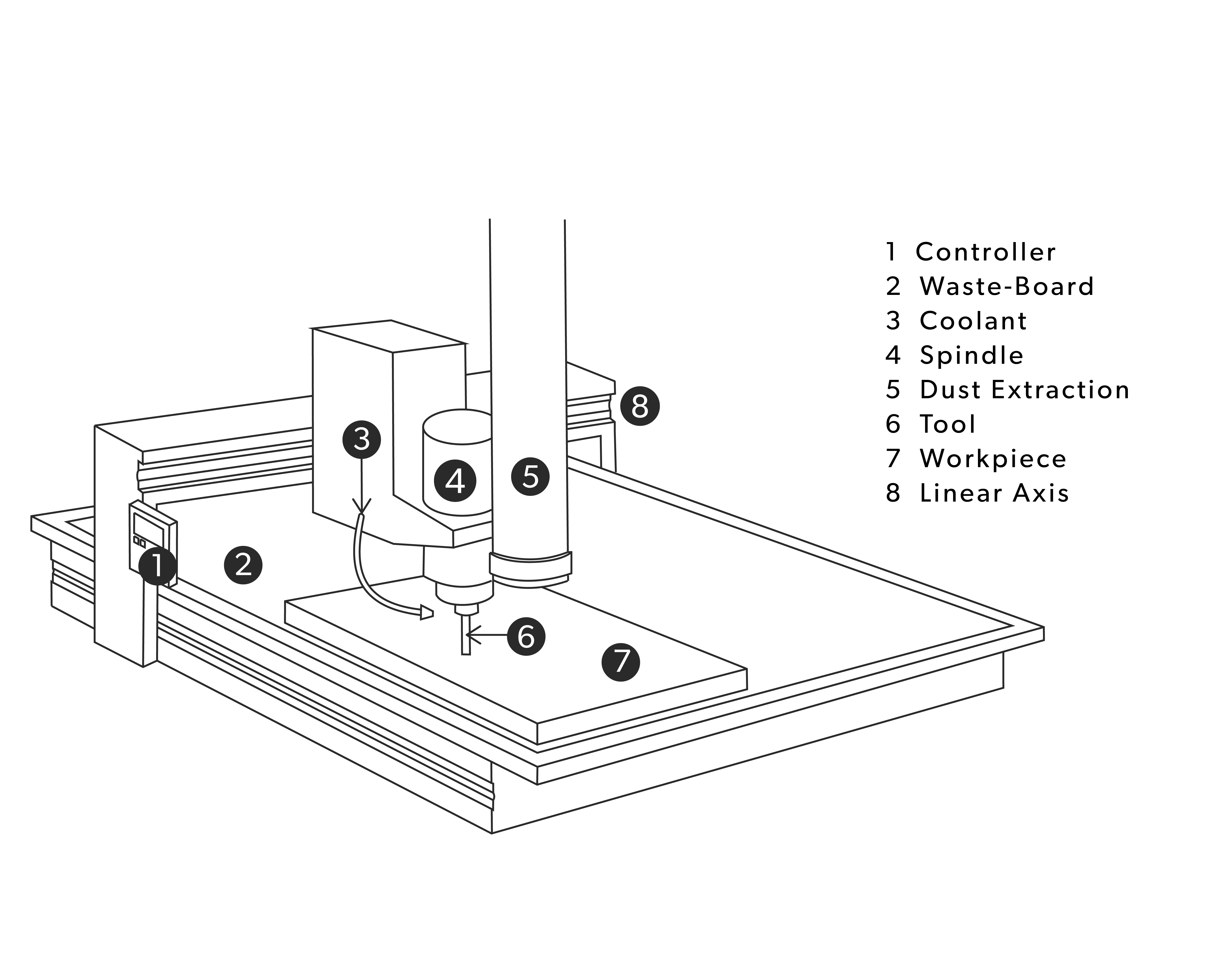

What is CNC Machining?

Computer numerical control (CNC) machining is a highly advanced manufacturing process that uses computer-guided tools such as mills and lathes. These tools can produce exact and intricate parts and products with extreme accuracy. The CNC machines are controlled by computer instructions that guide the machines’ movements, speed, and direction, ensuring that the final component meets the required specifications. The CNC machining process offers many advantages over traditional manufacturing methods, including increased precision, faster production times, and greater consistency in product quality. CNC machining is a widely used manufacturing capability in various industries, such as aerospace & defense, automotive, medical device manufacturing, etc.

CNC Machining Guide: Types of CNC Machines

Prototek maintains an extensive collection of computer numerical control (CNC) machines. These machines manufacture parts and components with high accuracy and precision, allowing for the creation of complex geometries and intricate designs for our customers. The CNC machines at Prototek are regularly maintained and updated to ensure optimal performance and maximum efficiency. Prototek can produce parts in various materials, including metals, plastics, and composites, and a wide range of machines are available.

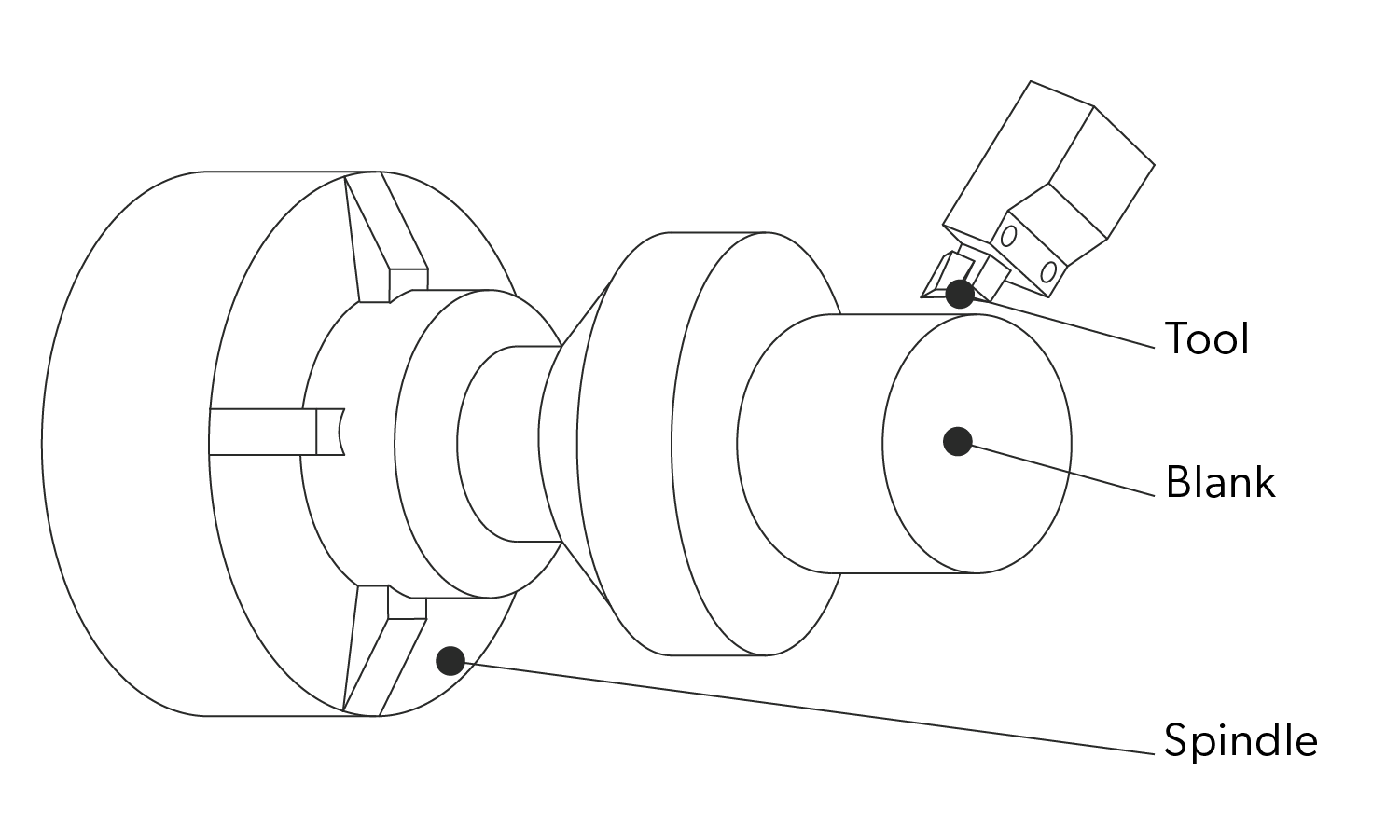

CNC turning is a manufacturing process that uses a computer-controlled machine called a CNC lathe to create cylindrical and symmetrical objects. The process involves a stationary cutting tool that removes material from a rotating workpiece. Our programmers program the CNC turning lathe to move the cutting tool along the workpiece to create the desired shape and dimensions in the software.

The raw material is secured to the lathe spindle to start the CNC turning process, which rotates the material at high speed. The cutting tool is then brought to the material, and small amounts are removed until the desired shape and dimensions are achieved. The machine clears away the removed material, which is called chips.

Once the turning process is complete, the finished part is inspected, and any necessary finishing or polishing is done. Our CNC turning service is a precise and efficient method for creating cylindrical shapes and is used in various industries, including automotive, aerospace, and medical.

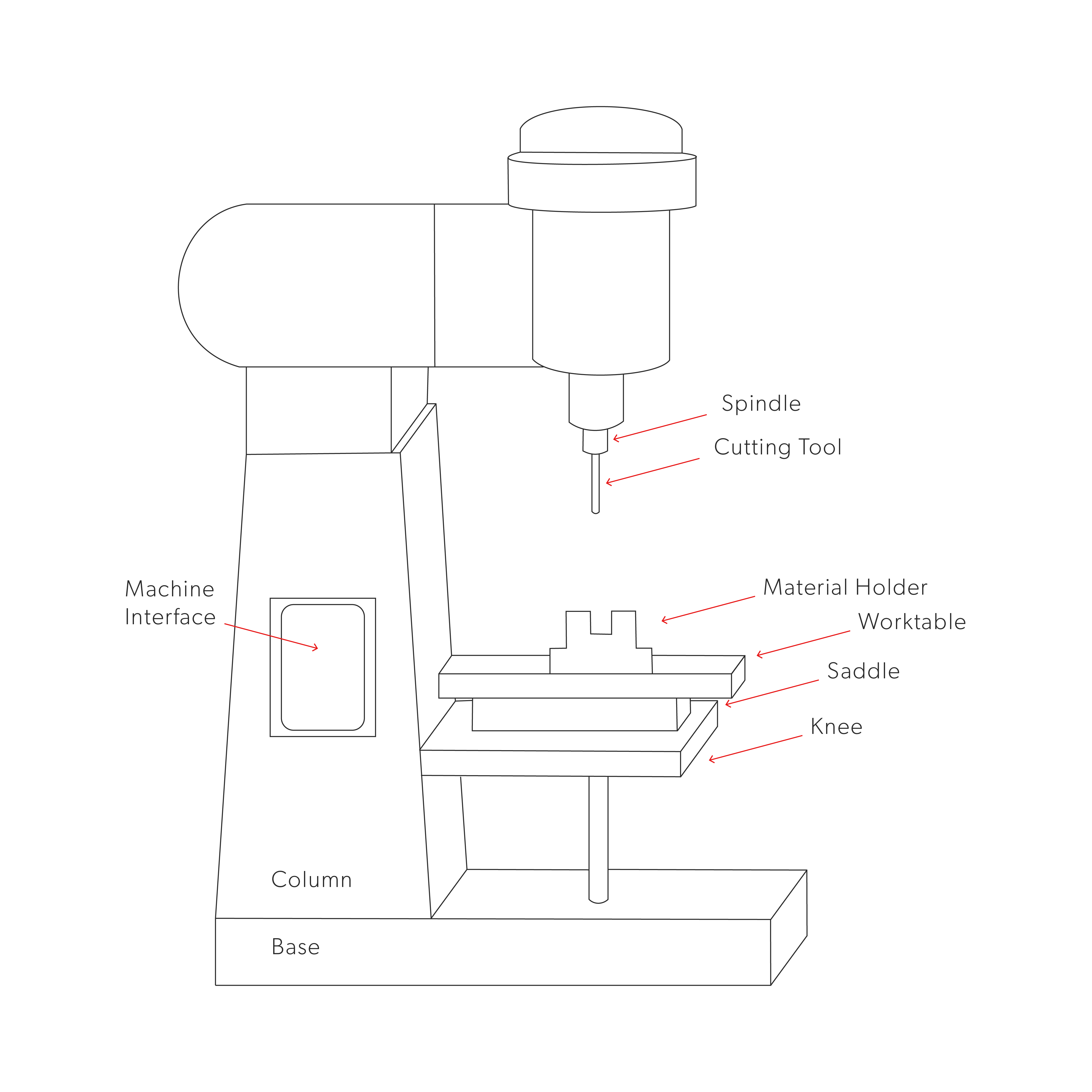

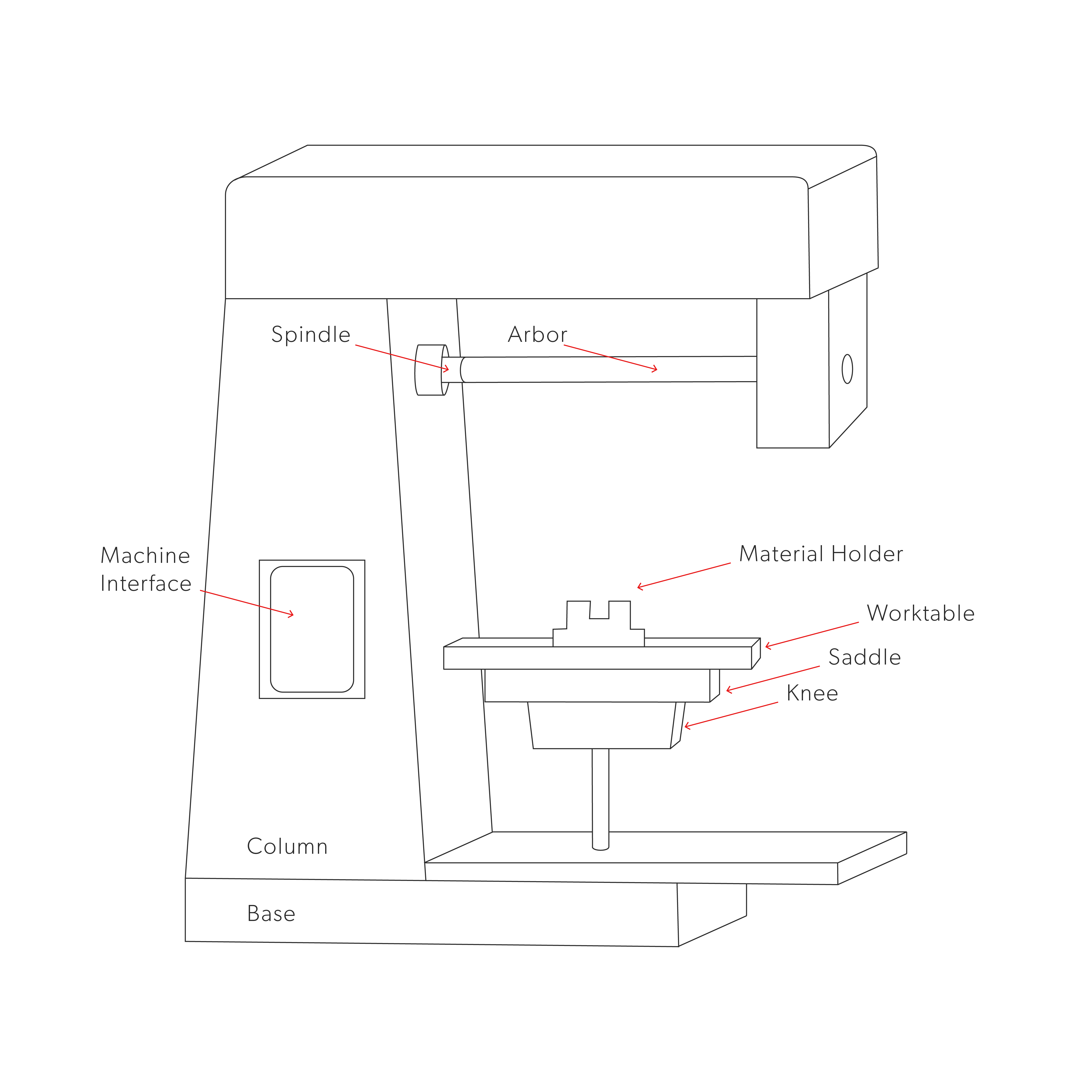

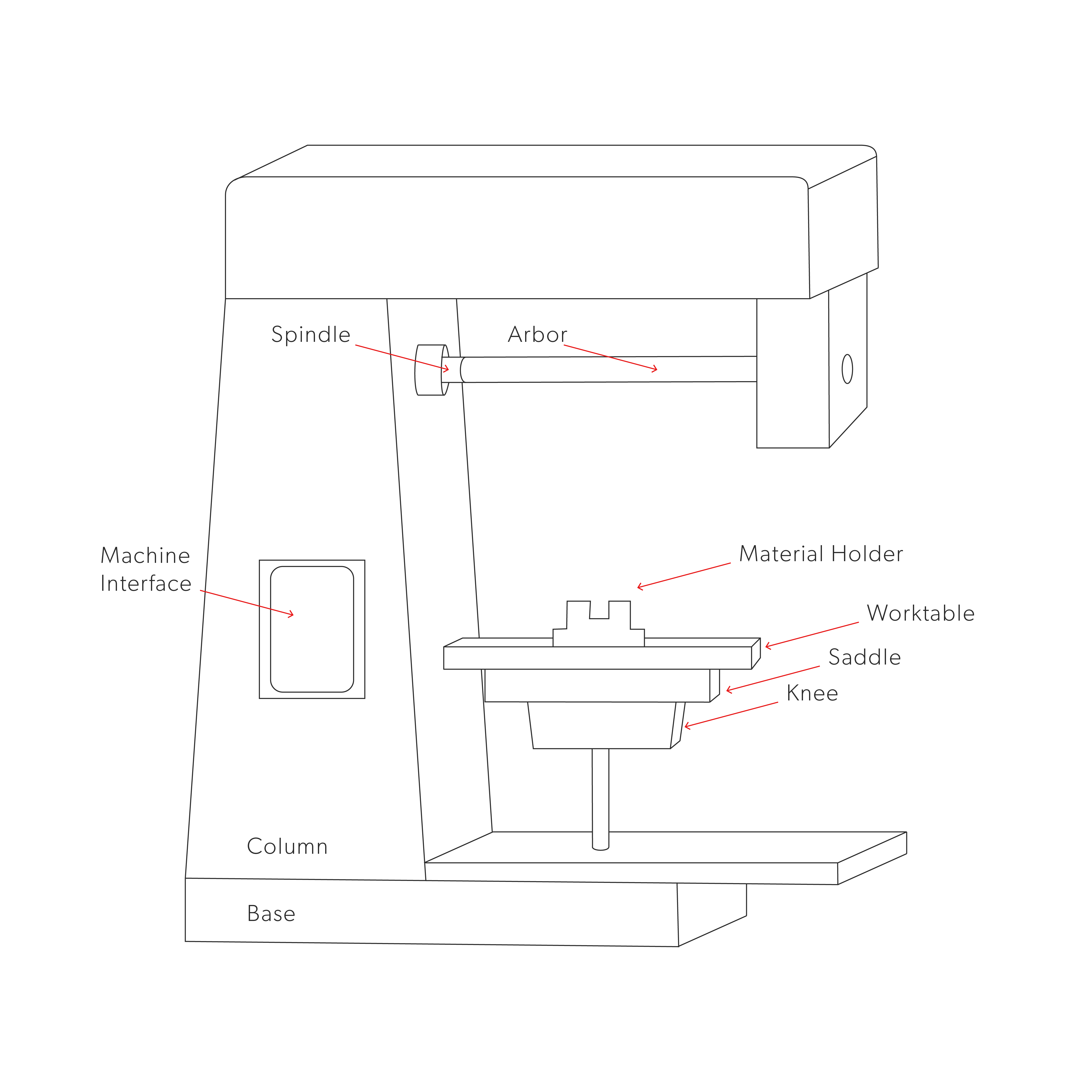

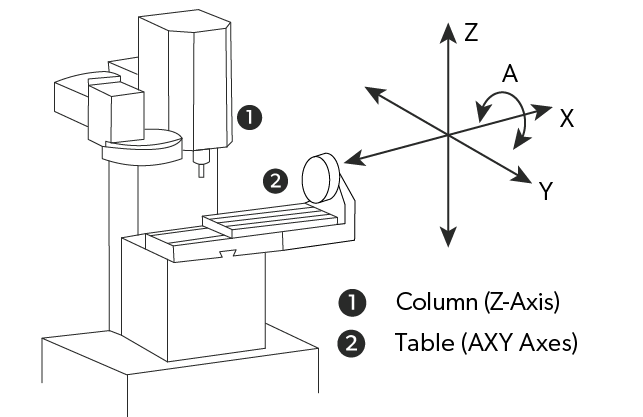

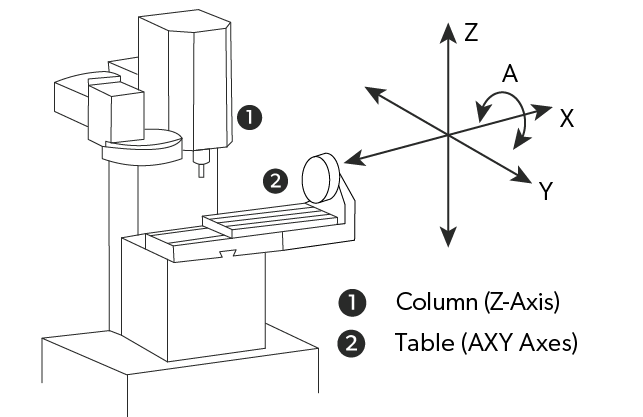

Vertical milling is a machining process that involves a drill press and tooling rotation that works primarily perpendicularly, which means that the cutting tool moves vertically, up and down.

In a typical vertical CNC milling machine, the tooling moves along the x-axis, y-axis, and z-axis. The x-axis moves the table from left to right, the y-axis moves it forward and backward, and the z-axis moves it up and down. By controlling the movement of the tool along these three axes, operators can create complex shapes and contours with high accuracy.

This process is particularly effective for creating parts with intricate features such as gears, molds, and dies. Overall, vertical milling is a versatile and precise machining process that offers many benefits for manufacturers looking to produce high-quality components.

Horizontal milling is a machining process that utilizes a horizontal spindle to machine the workpiece. It offers greater flexibility regarding the types of materials an operator can machine and the range of shapes and sizes that the machine can create. It provides more efficient machining than vertical milling, allowing for the simultaneous production of multiple pieces with larger workpieces and tools. The spindle in a horizontal milling machine is mounted parallel to the table, allowing for a broader range of milling operations, including slotting, grooving, and drilling.

The versatility of horizontal milling machines makes them an excellent choice for various industries, including aerospace, automotive, and manufacturing. They can handle a variety of materials, including metal, plastic, and wood, and can produce complex components with high precision. The machines also come equipped with various cutting tools and attachments, producing various parts with varying shapes and sizes.

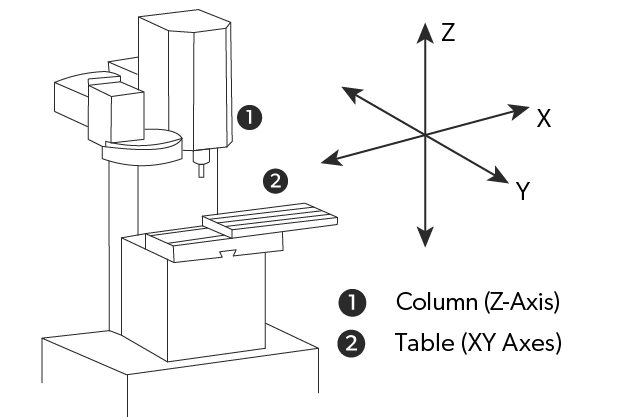

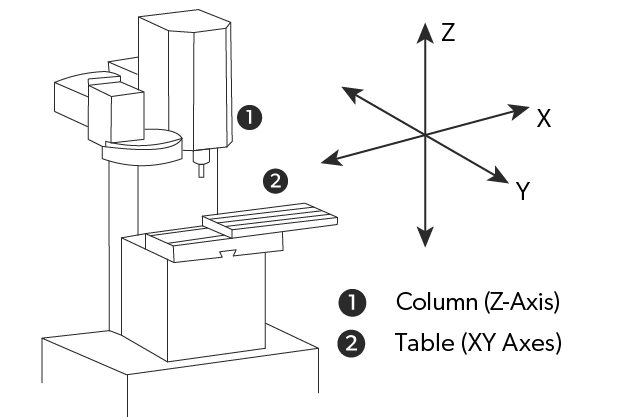

With 3-axis CNC milling, the cutting tool uses three axes to remove material from a stationary object. These three axes are typically the X, Y, and Z axes. The X-axis is horizontal and runs left to right, the Y-axis is vertical and runs up and down, and the Z-axis is perpendicular to the other two and runs forward and backward.

3-axis milling is ideal for creating complex shapes, holes, and sharp edges in metal, plastic, and wood materials. The aerospace, automotive, and manufacturing industries commonly use 3-axis CNC milling to produce components. This type of milling allows for precise cuts and a high degree of accuracy, making it a popular choice for creating intricate parts. Additionally, 3-axis milling machines are versatile and use these machines for various applications, from prototyping to full-scale production.

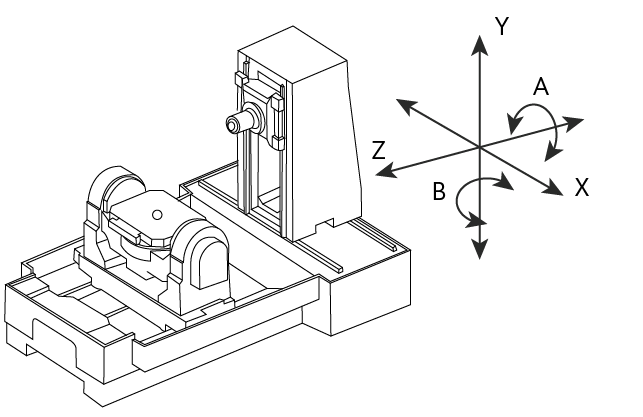

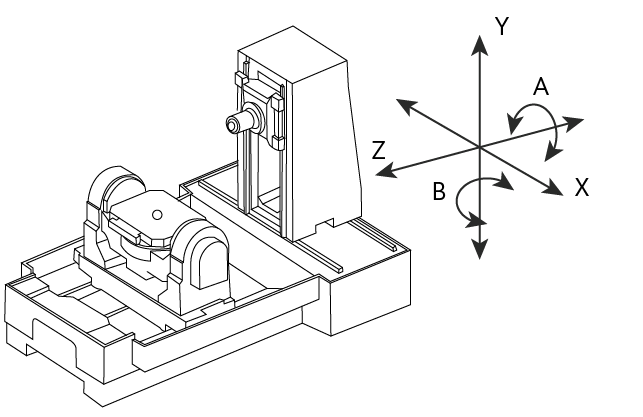

4-axis CNC milling is a machining process that involves using a machine tool with four axes that can move simultaneously to produce complex shapes and features. The machine operates on multiple axes, including the X, Y, and Z axes, and an additional rotation around one of the axes known as the A-axis. This extra rotational capability allows the machine to create intricate cut-outs on the side of a workpiece, such as slots, pockets, and other complex shapes. The A-axis can be combined with the other three axes to produce complex 3D shapes that would be difficult or impossible to create using traditional 3-axis milling techniques. Overall, 4-axis milling is a powerful and versatile machining process that allows manufacturers to produce high-quality, complex parts with precision and efficiency.

5-axis milling machines are advanced tools capable of producing complex parts for various industries. These machines incorporate four axes of 4-axis machining, which enable them to move the cutting tool along three-dimensional planes. The fifth axis is rotational (B-axis), allowing the cutting tool to move around the machined part. This additional axis gives 5-axis milling machines a level of flexibility and precision unmatched by other machines. This technology allows manufacturers to produce intricate parts with complex geometries, including parts with undercuts, radii, and steep angles. The 5-axis milling machines are an excellent choice for industries that require high precision and accuracy, such as aerospace, automotive, and medical.

A 9-axis mill-turn is a highly advanced, sophisticated precision engineering and manufacturing tool. It is similar to a 5-axis machine in its basic capabilities but offers much more. In addition to the X, Y, and Z axes, 9-axis mill-turn machines can move the workpiece along the B-axis and use additional tools to create intricate and complex parts.

One of the primary advantages of a 9-axis mill-turn machine is its ability to perform angle milling. This process cuts and shapes a workpiece at an angle, allowing for more intricate and complex designs. The machine’s additional tools, such as drills, taps, and reamers, can also be used to make holes and other features in the workpiece.

Another advantage of a 9-axis mill-turn machine is its ability to perform balance turning. This process involves turning a workpiece while maintaining balance, allowing for more precise and accurate cuts. It is beneficial when working with delicate or complex parts that require a high degree of precision.

A 9-axis mill-turn machine is a versatile and powerful tool for creating complex parts for various industries, including aerospace, automotive, and medical. Its advanced capabilities make it an essential tool for precision engineering and manufacturing.

A CNC router is a highly advanced manufacturing process that uses computer-controlled machines to cut and carve materials such as wood, plastic, and metal into desired shapes. The machines are programmed to read instructions that guide the cutting and shaping process. The CNC machines use rotating cutting tools and precise movements to remove material from the workpiece. The cutting tools are precisely positioned by the computer, ensuring that the material is removed with high accuracy. CNC routers are used in various industries, including woodworking, metalworking, and plastic fabrication. They are handy for creating complex shapes and patterns that would be difficult or impossible to produce with traditional manufacturing methods. CNC routers have revolutionized the manufacturing industry by increasing productivity, reducing waste, and improving the quality of finished products.

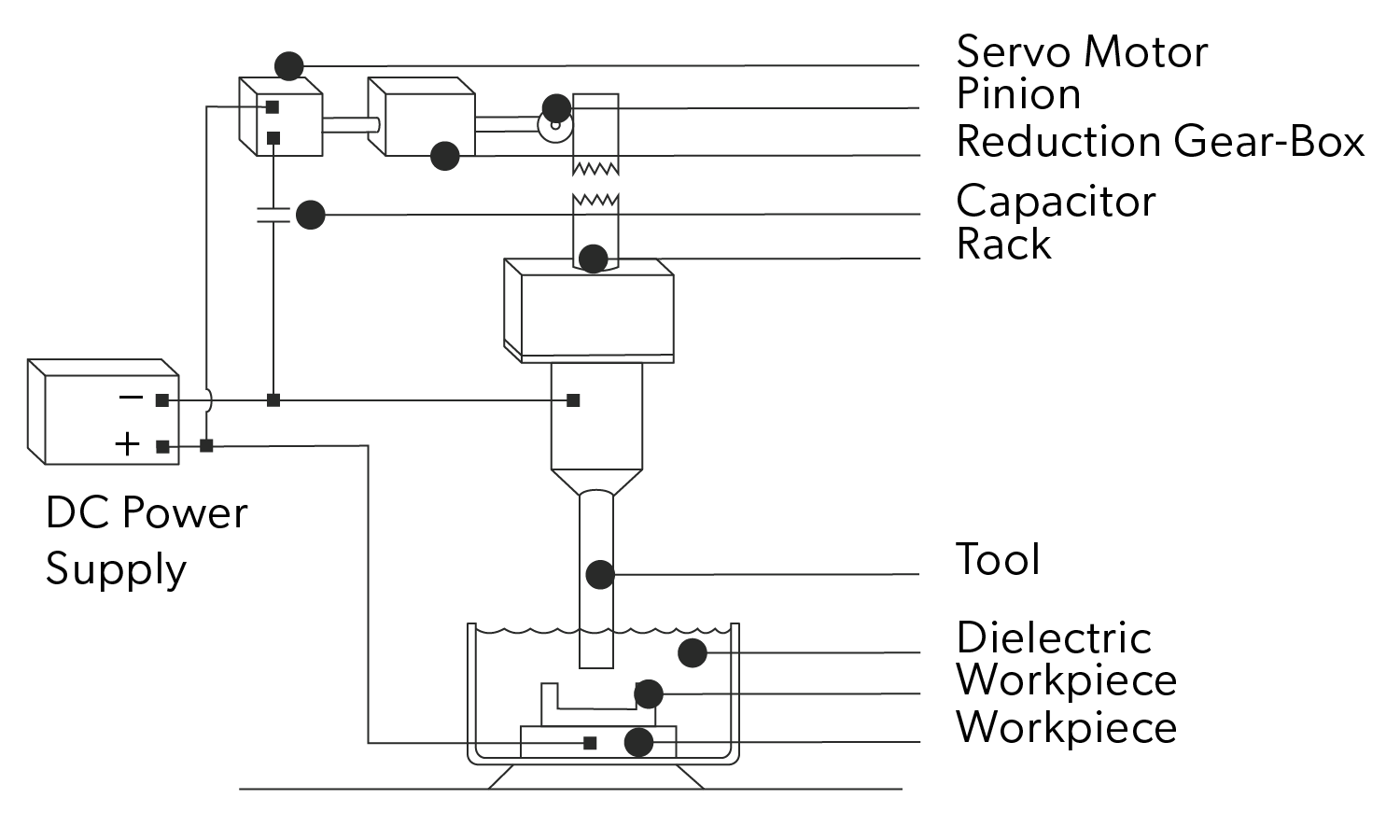

Sinker EDM is a manufacturing process that involves submerging a shaped electrode (usually made of graphite or copper) and a workpiece in an electrically conductive fluid. A controlled electrical charge passes between them. As the electrode approaches the workpiece, it creates sparks, melting the material on its surface. The fluid flushes the melted material away, and the electrode contours the shape of the design.

Although the electrical charge used is very high, it only lasts briefly. The process requires precise control since the electrical discharge can damage the workpiece to achieve the desired shape. Sinker EDM creates tools, dies, and molds for the automotive, aeronautical, and medical industries.

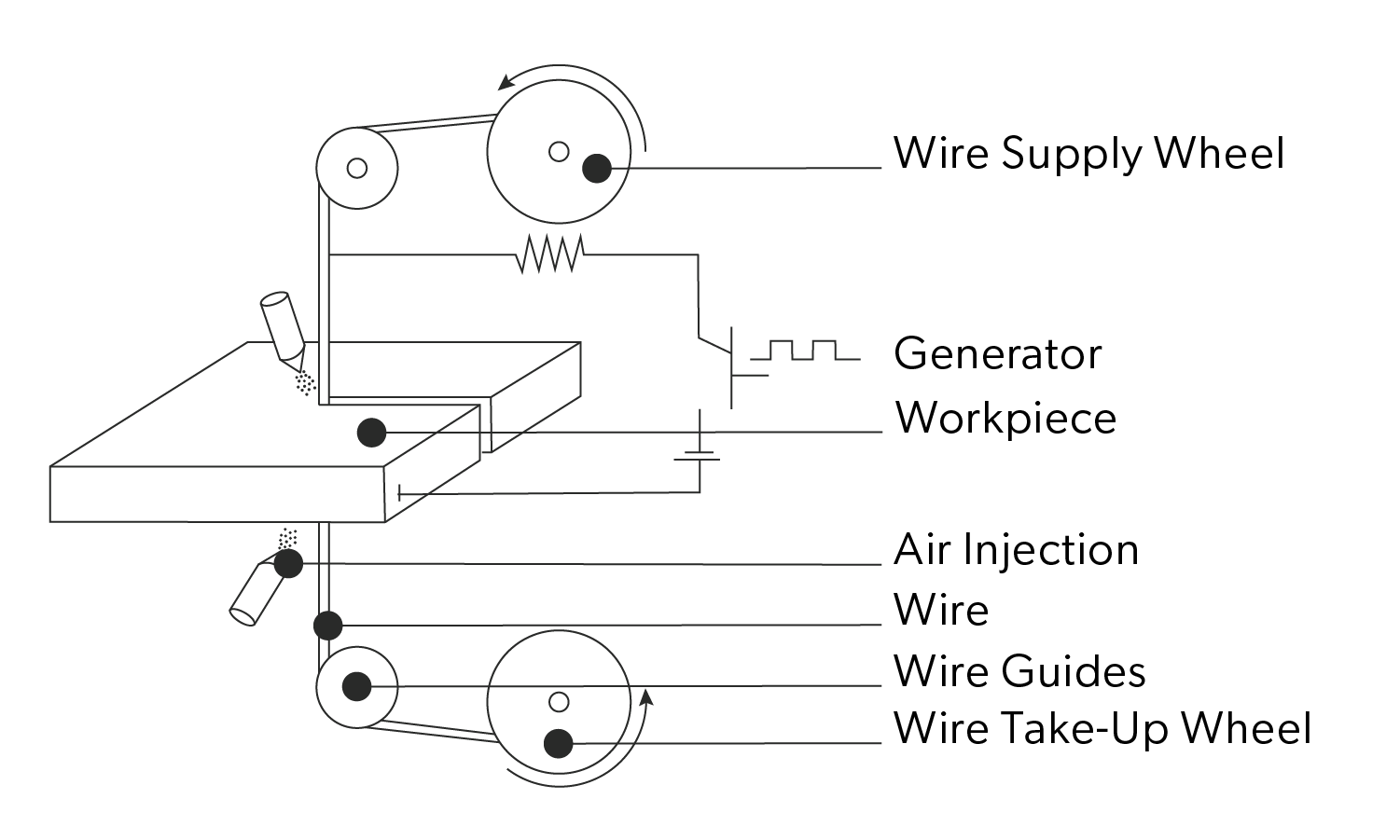

Wire EDM is a machining process that utilizes electrical energy to cut through hard materials precisely. It involves a thin, electrically charged wire that creates precise cuts through electrically conductive materials like metals. During the process, an electrical discharge is applied to the wire, creating a spark that melts the workpiece’s surface. A dielectric fluid then flushes away the melted material and circulates the cutting area. The wire electrode continuously moves while producing electrical discharges, creating a path that forms the shape of the desired final component. Its high precision and accuracy make Wire EDM ideal for aerospace, medical, and automotive applications, where tight tolerances are required.

Consider this before a CNC machining project.

Advantages to CNC Machining

- Produces parts with exceptional accuracy and precision.

- Achieves tight tolerances that meet the required specifications.

- Materials have properties for high-performance applications.

- Suitable for both prototypes and production.

Disadvantages to CNC Machining

- Start-up costs are higher than other manufacturing processes.

- Some forms of machining can be time consuming.

- Design limitations exist due to tool access, which varies with the number of axes on the machine.

CNC Machining Guide: Materials

At Prototek, we offer our customers a diverse range of high-quality materials in our machine shops. Our materials are carefully selected to meet the needs of a wide range of industries. Among our options are metals such as aluminum, brass, copper, and stainless steel, as well as plastics like ABS, polycarbonate, and nylon. If you are looking for a specialty material that your project requires, don’t hesitate to contact a Solutions Manager to find out if we can source that material. With our commitment to quality and customer satisfaction, you can trust that the materials you receive from Prototek will meet your specific needs and exceed your expectations.

Metals

Aluminum is a highly versatile material that finds its application in various industries, such as aerospace, automotive, and medical, owing to its unique blend of durability and lightness. Its high precision and flexible manufacturing properties make it a popular choice for producing components that meet specific requirements. Aluminum’s toughness and longevity make it ideal for manufacturing critical components for different industries.

Brass is a common material in manufacturing and machining processes because of its durability and excellent mechanical properties. It is highly corrosion-resistant, has good conductivity, and has high tensile strength. Brass finds numerous applications in industries like aerospace and automotive, where high-precision parts and components are required. It also creates decorative and ornamental objects such as figurines or sculptures.

Bronze is a highly corrosion-resistant metal that finds its applications in diverse industries such as aerospace, automotive, marine, and medical. It is commonly used to manufacture valve components, bearing housings, gears, and bushings. Our machinists are highly skilled and use precise equipment and techniques to shape the material per the design requirements. Bronze is a versatile material that is easy to work with and is available in various shapes and sizes.

Copper is a metal that can be shaped and stretched without breaking. It is a popular material due to its excellent mechanical properties, such as thermal and electrical conductivity, resistance to rusting, and ability to kill bacteria. Polishing, coating, and plating are methods that improve the appearance and functionality of copper. Copper’s unique properties and durability make it a popular choice in the electronics, automotive, aerospace, and medical industries.

Inconel is a superalloy made primarily of nickel, chromium, and iron. Due to its unique properties, aerospace, medical equipment, and chemical processing industries widely use Inconel. The material is available in various grades tailored to specific applications and environments. However, machining it can be challenging. High-end applications such as aircraft engines, gas turbine components, nuclear reactors, medical implants, and surgical instruments use Inconel because of its biocompatibility and resistance to corrosion.

Invar is a unique type of superalloy with a very low thermal expansion coefficient. It does not significantly expand or contract when exposed to changes in temperature, making it ideal for use in precision instruments and scientific applications where dimensional stability is critical. Invar is composed of a precise combination of nickel, chromium, and iron, with deficient levels of impurities. Its unique properties make it popular in electrical and electronic devices, scientific instruments, and aerospace engineering applications.

Kovar is a type of iron-nickel-cobalt alloy that exhibits a unique combination of properties, including low coefficient of thermal expansion (CTE), high thermal conductivity, and excellent oxidation resistance. These features make Kovar ideal for electronic and optical applications, such as airtight seals, vacuum tubes, and X-ray tubes. Additionally, Kovar is easy to machine and has good weldability, further adding to its versatility and utility in various industries.

Nitronic 60 is a high-performance austenitic stainless steel with exceptional strength, corrosion resistance, and wear resistance even at elevated temperatures. It is composed of a unique combination of elements, including chromium, nickel, silicon, manganese, nitrogen, and iron, making it ideal for various demanding industrial applications, such as aerospace, chemical processing, and marine engineering. Nitronic 60 offers superior mechanical properties to standard austenitic stainless steels, making it an excellent choice for components requiring high strength, toughness, and durability in harsh environments.

Stainless steel is a type of steel that has undergone a machining process. It is known for its high strength, corrosion resistance, and aesthetic appeal, making it a popular manufacturing choice. However, machining stainless steel can be challenging because of its hardness and rigid properties. The aerospace, automotive, and medical industries typically use stainless steel with grades 304, 316, and 420. Consequently, we machine stainless steel components in various sizes and levels of complexity for use in applications such as surgical instruments, automotive components, and industrial machinery.

Mild steel is a low-carbon metal alloy composed of iron and carbon. It is highly versatile and widely used in manufacturing due to its excellent properties, including good machinability and weldability. It offers strength, toughness, and flexibility, making it ideal for various applications.

Titanium is a strong, lightweight metal that can be shaped and cut with precision machines to create components with unique properties. These components possess exceptional strength, making them ideal for applications where durability is critical—in addition, creating lightweight machined components due to titanium’s low density without sacrificing strength. Furthermore, titanium is highly resistant to corrosion and can withstand harsh environments, such as those with high moisture levels, salt, or acid. Surface treatments such as anodizing or passivation can further enhance the properties of titanium components.

Tool steel is a durable and resilient alloy that is extensively used in precision operations and cutting machinery in various industries, such as automotive and aerospace. Its composition includes tungsten, chromium, and vanadium, which enhance its wear resistance, corrosion resistance, and strength. Engineers use heat treatment processes to increase the alloy’s hardness and toughness, improving its durability.

Other Materials

G-10 is a composite material of woven fiberglass impregnated with an epoxy resin binder. This material is known for its exceptional strength, durability, and versatility. It has high heat, moisture, and chemical resistance, making it ideal for various applications, including electrical insulation, circuit board substrates, and knife handles. Additionally, the G-10 is lightweight and easy to machine, which makes it a popular choice for creating custom parts and components. Its ability to withstand extreme conditions and maintain its structural integrity makes it a reliable and cost-effective option for various industries.

Macor is a high-performance glass-ceramic material with unique properties, including excellent electrical insulation, high-temperature resistance, and exceptional machinability. It is often used in applications that require high precision and tight tolerances, such as aerospace, semiconductor, and medical industries. Additionally, Macor is biologically inert, making it an ideal choice for medical implants and laboratory equipment use.

Wood is a common material used in CNC machining, a computerized manufacturing process that involves removing material from a workpiece using precision cutting tools. Wood is a versatile material that can be useful for creating a wide range of products, from furniture and cabinetry to musical instruments and decorative items. Its natural beauty and warmth make it popular for functional and aesthetic purposes. In addition, wood is relatively easy to work with and can be machined to exact specifications, making it ideal for CNC machining.

Plastics

ABS is a versatile thermoplastic material that blends acrylonitrile, butadiene, and styrene. It is lightweight, impact-resistant, and dimensionally stable, making it ideal for durable products. ABS is also resistant to chemicals and abrasives and can be machined efficiently, making it a popular choice for mass-produced items.

Acrylic is a lightweight, durable, and versatile plastic material, making it a preferred option in the manufacturing industry. It is also highly resistant to weather conditions, easy to maintain, and can withstand chemical damage and impact, making it ideal for a wide range of applications. Some common uses of acrylic include automotive parts, medical equipment, lighting fixtures, and display cases.

Acetal is a type of thermoplastic made from POM resin. It is highly regarded for its outstanding mechanical properties, including its resistance to abrasion, chemicals, and oils. Additionally, it has low moisture absorption and is easy to machine, making it ideal for a wide range of applications. Some of the most common uses for acetal include gears, bearings, bushings, and electrical components in industries like healthcare, automotive, aerospace, and industrial manufacturing.

High-density polyethylene (HDPE) is a strong plastic that is excellently resistant to moisture, chemicals, and weather. Due to its lightweight, it is easy to handle and widely used in various fields, including conveyor components, tanks, machinery parts, food processing equipment, medical devices, and marine components. The FDA has approved it, and it is suitable for use in environments with water. In summary, machined HDPE is the perfect plastic for those seeking strength, resistance, and versatility.

Nylon is a thermoplastic material known for its durability, strength, and lightweight properties. Due to these characteristics, it is a popular choice for various applications. It can be easily machined to produce complex shapes and parts of different sizes, making it a versatile material for multiple industries. CNC machining is a process that involves cutting, drilling, and milling nylon to create high-quality finished products with precise specifications. The aerospace, medical, automotive, consumer electronics and industrial industries use nylon because of its excellent resistance to impact, chemicals, and wear. This makes it the perfect material for use in demanding environments.

PEEK is a highly versatile polymer with excellent mechanical and thermal properties. Its high melting point of 550°F (288°C) makes it highly resistant to heat and extreme temperatures. Additionally, it exhibits excellent resistance to harsh chemicals and radiation, making it a preferred material in various industries. PEEK’s tight tolerances and accuracy in various shapes and sizes make it a popular choice in the aerospace, automotive, medical, and semiconductor industries.

Polycarbonate is a thermoplastic known for its high strength and durability, making it a popular choice in various industries. Its clear/translucent composition also makes it a sought-after material for applications that require good visibility, such as medical devices, aircraft windows, and machine parts.

Polycarbonate is also lightweight, making it an excellent choice for applications requiring solid materials that do not weigh too much. It is also resistant to impact, making it an ideal material for products prone to rough handling or accidental drops.

Polypropylene is a type of thermoplastic polymer widely used in various industries due to its versatility, durability, and chemical resistance. It is highly machinable, allowing for the creation of parts and products tailored to specific applications with high precision. In particular, the automotive, construction, and medical sectors use polypropylene for its impressive strength, lightweight construction, and tolerance to high temperatures. Owing to these exceptional attributes, polypropylene’s popularity is on the rise.

Teflon, or PTFE (Polytetrafluoroethylene), is a synthetic fluoropolymer of tetrafluoroethylene. It is a highly versatile material with a wide range of applications due to its unique properties. Teflon is known for its non-stick capabilities, high-temperature resistance, chemical inertness, and low friction coefficient. These properties make it ideal for cookware, electrical insulation, industrial piping, and many other applications. Teflon has excellent electrical insulation properties, making it a popular choice in the electronics industry.

Ultem is a highly dependable material for applications in diverse industries, including automotive, medical, and aerospace. It offers exceptional strength, durability, and unparalleled mechanical and dimensional stability. With CNC machining, Ultem components can be manufactured with great precision and reproducibility, making them ideal for both small—and large-scale manufacturing operations. Ultem components are well-known for their high-quality standards, toughness, and resilience to harsh environmental conditions such as high temperatures, chemicals, and flame resistance.

Does your project require a specialty material? Let us know, and we’ll see if we can source it for you. Quotes may take a little longer.

CNC Machining Guide:

Design Recommendations

CNC machining is an essential tool in the manufacturing industry. Prototek has a team of highly skilled machinists and programmers who use CAD drawings to create precise and accurate prototypes and parts. In this section of the CNC Machining Guide, we will explore ways to save money and achieve better project outcomes by improving design and process understanding.

Designing a part for CNC machining can be challenging due to the lack of industry-wide standards. CNC machines and tools constantly evolve, expanding the possibilities of what can be achieved. To help with this, the table below summarizes recommended and feasible values for the most common features encountered in CNC machined parts.

Limitations to CNC Machining

Machining uses different tools and equipment to shape and cut materials into a desired form. Although it can be precise and accurate, it has certain limitations that should be considered when designing a machined part. Accessibility and complexity should be carefully evaluated before machining to ensure the best possible outcome.

Tool Dimensions

CNC machining cutting tools are highly accurate for shaping and carving various materials. They come in multiple sizes and shapes to cater to different applications. When designing your part, it is essential to consider the tool’s dimensions. Since these tools are cylindrical, there will always be a radius at internal corners, irrespective of the cylinder size.

Accessibility Issues

It is essential to note that certain surfaces may be inaccessible to the cutting tool. This can limit the maximum depth of an undercut achieved during fabrication and may make it impossible to create parts with hidden internal geometries. In other words, any areas that cannot be reached by the cutting tool will not be able to be machined. This can cause a limitation in the design of parts, as the creation of internal geometries that are not easily accessible to the cutting tool can be a challenge. It is essential to consider these considerations when designing parts for CNC machining to ensure that the finished product is high quality and meets all necessary specifications.

Geometric Complexity

Complex geometries may be achievable but will increase the time and cost of your project due to the number of tool changes and machine setups required.

CNC Machining Design Guide

Designing a high-quality component suitable for CNC machining requires a thorough understanding of the manufacturing process and the design principles involved. This involves a range of considerations, including the material to be used, the machining operations required, and the intended function of the component. It is essential to consider the limitations and capabilities of the CNC machine and the potential for any errors or defects that may arise during the machining process. Additionally, the design details, such as tolerances, surface finish, and geometry, must be paid attention to, which can significantly affect the final product’s performance. Overall, designing a part for CNC machining requires a careful balance of technical knowledge, creativity, and attention to detail to ensure optimal results.

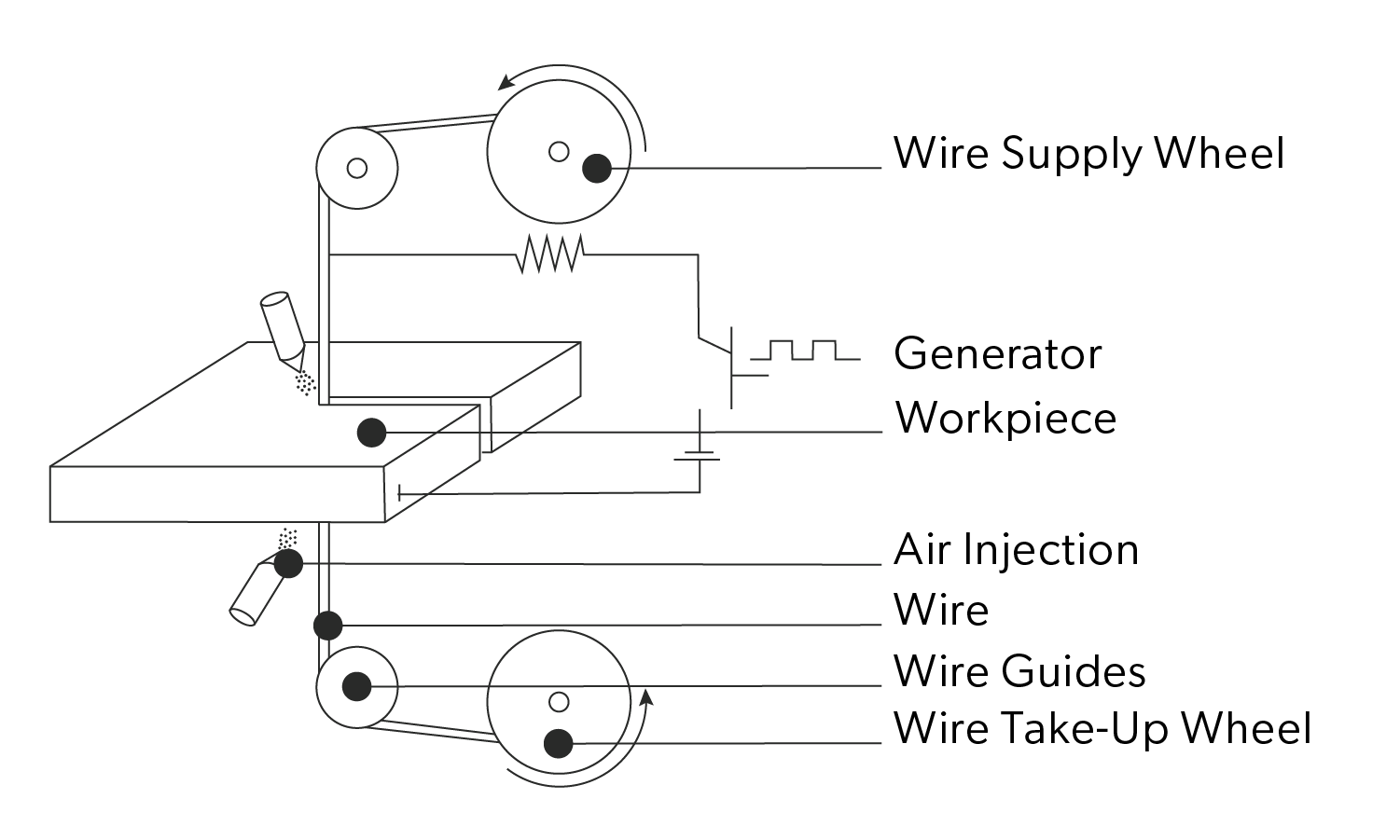

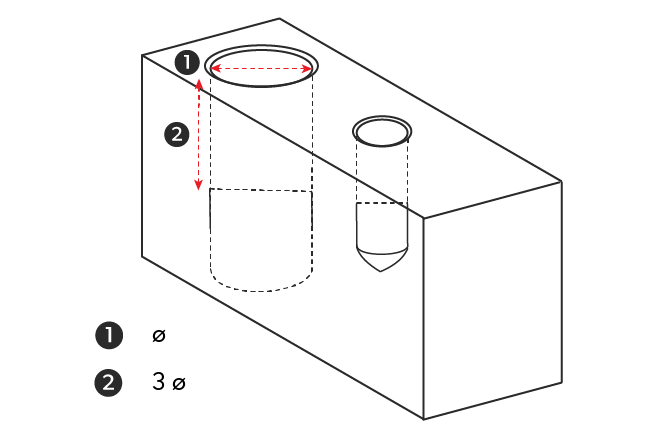

Cavities and Pockets

Recommended: Depth is less than 10ø of the tool

When designing pockets and cavities for CNC machining, it’s essential to consider the cavity’s depth, as it significantly impacts the size of the tool required. The deeper the cavity, the larger the tool needed to machine it. Additionally, the depth of the cavity can also affect the radii and fillets in the design, which should be adjusted accordingly to ensure the best possible outcome. Considering these factors, you can create a design optimized for CNC machining to produce the desired results with the best possible accuracy and efficiency.

Engraving

Recommended: .125 in high character minimum

When engraving on CNC machined pieces, consider the material, size, font, depth, location, and engraving tool. Different materials require different techniques. The text should be appropriately sized and clear to read. The engraving depth should be enough but not affect the piece’s structure. Choose a visible and aesthetically pleasing location.

Note: Use “stick” letters for the best outcome.

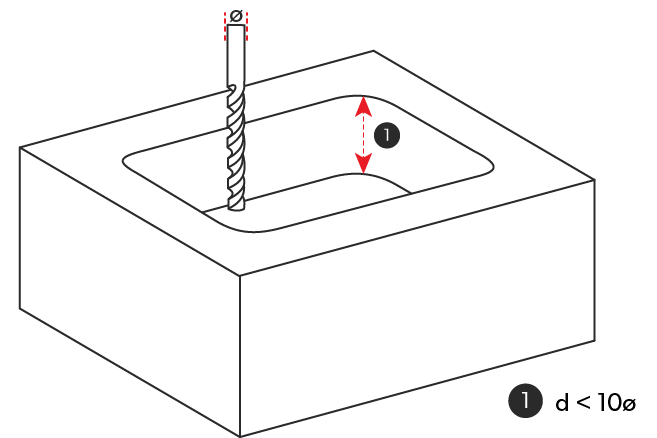

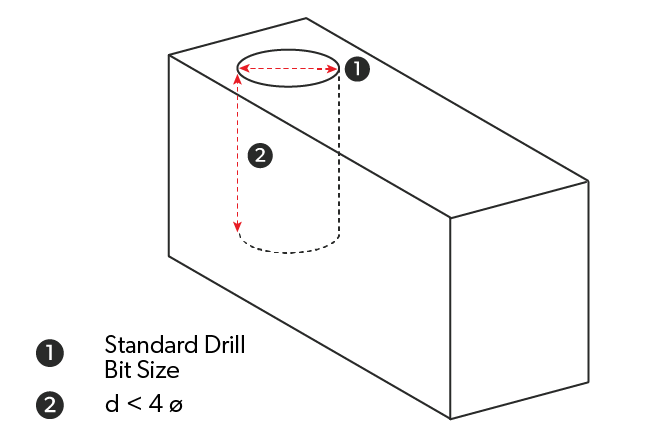

Holes

Recommended: ø = Standard Drill Bit Sizes and d > 4ø

Feasible: d ≤ 10ø

Various factors must be considered when designing parts containing holes. The hole’s size, shape, and orientation can affect the part’s structural integrity and impact functionality. The material properties and manufacturing processes can also influence the hole’s accuracy and quality. It is also essential to consider the environmental conditions and potential stresses the part may be exposed to in its intended application. Proper consideration of these factors can result in a well-designed part that meets the desired specifications and performs optimally.

Note: On blind holes, remember to account for the drill point depth. Measure the depth to diameter of the drill bit, but remember that the point will extend further.

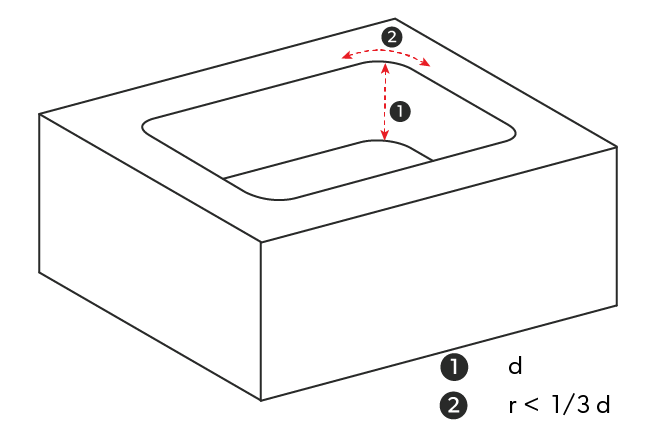

Internal Edges

Recommended: For corners r > 1/3 d, the radius is 10% greater than the closest standard tool size.

If the closest tool diameter is 0.25 in, we suggest using a 0.125 in x 1.1 = 1.375 radius to prevent tool gouging. Milling tools perform better with continuous operation.

When designing parts for CNC machining with internal edges, it is crucial to consider the radii of those edges. The radii refer to the curvature of the edges, and they play a significant role in determining the cutting tool size that should be used for the machining. If the radii are too small, a smaller cutting tool will be needed, and conversely, if the radii are too large, a significant cutting tool will be required. Standard drill bit sizes are commonly used in CNC machining, making finding the right cutting tool easier.

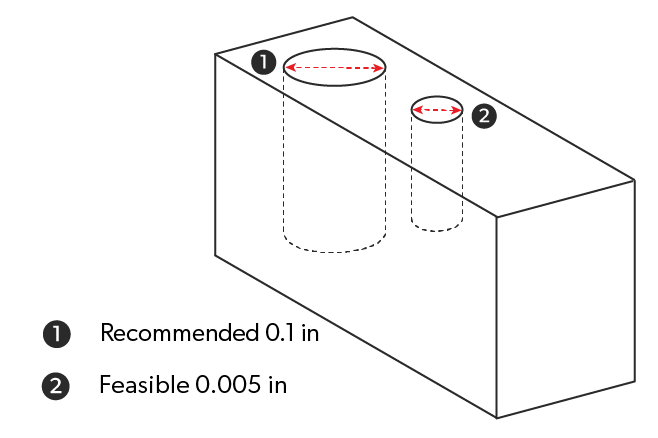

Minimum Features

Recommended: 0.10 in

Feasible: 0.005 in

When designing minimum features for CNC machining, it’s essential to consider various factors. These may include the size and complexity of the part, the type of material being used, the intended purpose of the part, and the capabilities of the specific CNC machine being used. Additionally, the designer needs to think about the type of tooling that will be required and the machining process that will be used. By taking all of these factors into account, the designer can ensure that the minimum features of the part will be accurately and efficiently machined.

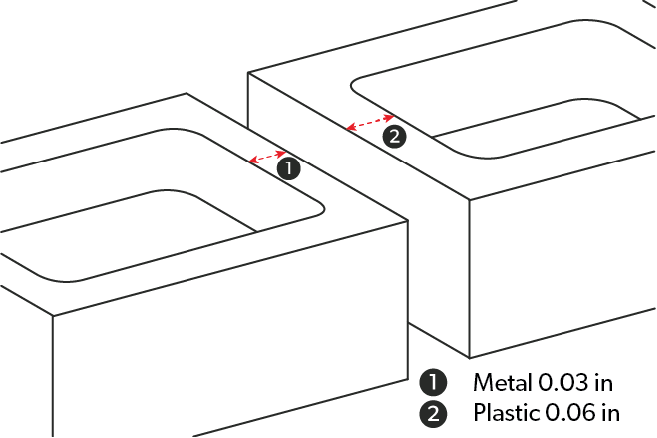

Thin Walls

Recommended: Metal materials 0.03 in and plastics materials 0.06 in

Feasible: Metal materials 0.02 in and plastic materials 0.04 in

When designing parts for CNC machining, it is crucial to pay close attention to the thickness of walls. This is because walls that are too thin can easily break or warp during the machining process, ultimately leading to a subpar final product. Additionally, overly thick walls can make the part heavier and more expensive to produce. Therefore, it’s essential to balance thickness and durability while also considering the specific needs and requirements of the designed part. By considering these factors, designers can create functional, durable, and cost-effective parts.

Threads

Recommended: The length is 3ø, and the thread size is 0-80.

When designing parts for CNC machining that require threaded features, it is essential to consider the thread type, size, and pitch. The thread type refers to the shape of the thread, whether it is a V-thread, square thread, or acme thread. The size of the thread refers to the diameter of the major and minor threads, while the pitch is the distance between consecutive threads. These factors are critical to ensure that the threads are compatible with the mating parts and that the part functions properly.

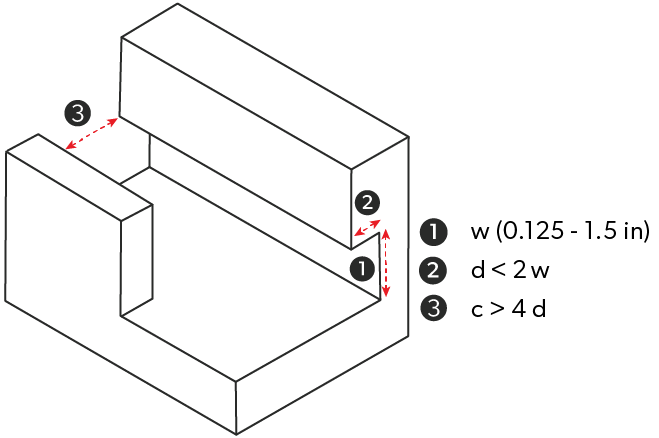

Undercuts

Recommended: The width of 0.125 in – 1.5 in, maximum depth of < 2w, and minimum clearance of > 4d.

Designers should consider specific guidelines when creating parts for CNC machining with undercuts. Undercuts require extra machining steps and can increase complexity and cost. To reduce impact, minimize depth and complexity, avoid sharp corners or abrupt transitions, and ensure clearance between feature and tool. Following these guidelines will optimize part designs for CNC machining and ensure high-quality production.

CNC Machining Guide: Finishes

Proper finishing is critical for CNC machine shop projects to ensure that the parts are functional and aesthetically pleasing. It also helps to eliminate defects. Our CNC machine shop offers a variety of finishes, including sandblasting, powder coating, anodizing, nickel plating, electroplating, painting, and polishing. Choosing the right finish for the material and application is crucial, and partnering with an experienced CNC machining service provider is essential to ensure quality. If you have any questions about our CNC machine shop finishes, please do not hesitate to contact us.

Anodizing II & III

Anodizing is a process that creates a thin oxide layer on CNC machined and sheet metal fabricated parts, which enhances their corrosion resistance and aesthetic appeal.

Bead Blasting

Bead blasting prepares surfaces by cleaning, polishing, or removing contaminants from materials such as metal, plastic, ceramic, and glass. This results in a textured or peened finish and improves the material’s appearance, strength, and durability.

Black Oxide

Black oxide coating is a chemical process that provides a colored finish to metal components. It enhances the metal’s durability, prevents rust and corrosion, improves its appearance, and increases its wear resistance.

Chem Film

Chem film is a cost-effective surface treatment used in aerospace and other industries to protect metals from corrosion and increase lifespan.

Dry Film

Dry film coatings reduce friction, prevent corrosion, and extend the part’s life. They work on all materials, improving machining performance.

Electroless Nickel Plating

Chem film is a cost-effective surface treatment used in aerospace and other industries to protect metals from corrosion and increase lifespan.

Epoxy Priming & Painting

Epoxy primer provides a base for the paint, prevents damage by harmful elements, and protects against corrosion. Once the epoxy primer cures, high-quality paint is applied, resulting in a durable finish.

Galvanizing

Galvanizing applies a zinc coating to steel or iron to prevent rust and corrosion. The construction, automotive, and manufacturing industries use it for its cost-effectiveness and ability to prolong the lifespan of metal.

Gold Plating

Gold plating improves the parts’ conductivity, corrosion resistance, and durability. Additionally, it adds an attractive finish, making them more appealing to customers.

Graining

Graining can significantly improve the surface texture and finish of CNC machined parts. It also reduces friction and wear, enhancing their longevity and performance.

Laser Engraving

Laser engraving uses a laser beam to etch, carve, or mark objects. A computer or software controls the laser beam. This method creates precise engravings with intricate designs, logos, and text.

Nickel Plating

Nickel plating is the electroplating process of coating a metal or plastic object with nickel. The automotive, aerospace, and consumer goods industries use nickel plating.

Passivation

Passivation is treating a metal surface to make it more corrosion-resistant. The process is also widely used in the automotive and electronics industries to protect parts and components from wear and tear caused by exposure to harsh environments.

Polishing

Polishing creates a smooth, reflective surface on metal or other materials. The medical and stainless steel appliance industries use polishing.

Powder Coating

Powder coating is a dry type of coating applied as a free-flowing dry powder, consisting mainly of pigments, resins, and additives. It results in a long-lasting, high-quality finish that is resistant to scratches, corrosion, and fading.

Priming & Painting

The two finishing processes, priming, and painting, can improve the durability, appearance, and branding of manufactured products by selecting colors and finishes according to aesthetic requirements.

Silk Screening

Silk screening is a cost-effective and versatile technique for improving the aesthetics of manufactured parts. It is a popular choice, and many industries use it for logos, designs, and other images.

Tumbling

Tumbling parts involve placing them in a container with an abrasive medium to remove imperfections. Different media types can be used, and the process can be done manually. Tumbling can add smooth and remove foreign debris from parts.

Zinc Plating

Zinc plating improves the corrosion resistance, appearance, wear resistance, and conductivity of CNC machined parts. It is a cost-effective method of enhancing the quality and durability of machined parts.

CNC Machining Frequently Asked Questions

Of course, we do! Prototek offers quick turn services.

Several factors should be considered to ensure that a CNC machining project is a quick-turn project. These include the design’s complexity, the specifications’ accuracy, the availability of the necessary materials and equipment.

Computer Numerical Control (CNC) machining is a manufacturing process that utilizes automated tools to control the movement and operation of machine tools. This process is widely used across different industries, such as aerospace, automotive, consumer electronics, robotics, and agriculture. CNC machining is commonly used in these industries to manufacture metal parts, such as engine components, airplane parts, electronic enclosures, and agricultural equipment parts.

Prototek offers a variety of machining services, including:

- CNC Lathes

- Vertical Milling

- Horizontal Milling

- 3-Axis

- 4-Axis

- 5-Axis

- 9-Axis Mill-Turn

- CNC Router

- Wire EDM

- Sinker EDM

CNC, NC, and DNC are all computer machine control systems. CNC stands for Computer Numerical Control, NC stands for Numerical Control, and DNC stands for Direct Numerical Control. Their main differences are in how they communicate with the machine and the user interface.

CAM (Computer-Aided Manufacturing) software controls and manages machinery in the manufacturing process. CAD (Computer-Aided Design) software, on the other hand, designs and creates digital models of products. While both are important, CAM software is focused on the production of physical objects, while CAD software is focused on digital design.

CNC machines function using a specific language known as G-code. This code issues instructions to the machine, directing it to perform accurate movements and operations. Although different machines may use slight variations of G-code, it is a standardized language widely accepted in the industry.

Helpful Links

Working with Prototek for Custom CNC projects.

Prototek is a CNC machine shop that offers reliable and high-quality services. Our team of experienced programmers and machinists ensures that all clients receive excellent service. We are committed to quality and customer satisfaction, using modern, high-precision machinery to create parts that meet and exceed our clients’ specifications. Our flexibility and willingness to adapt to our client’s unique requests make us an ideal choice for anyone looking for bespoke CNC machining services.