At Prototek Digital Manufacturing, we take immense pride in our state-of-the-art machine shop. Moreover, we leverage the latest and most advanced technologies to consistently deliver exceptional manufacturing solutions tailored to our client’s unique needs. This blog post will overview our extensive machine shop post-processing and finishes. From prototyping to full-scale production, the dedication of our skilled team ensures every project is executed with the utmost attention to detail and quality, enabling us to exceed your expectations in manufacturing.

Machine Shop Finishes

The finishing and post-processing stages in manufacturing are crucial for improving machined parts’ quality, functionality, and appearance. These techniques involve deburring, polishing, plating, painting, and other specialized methods to ensure that the final product meets tight tolerances, has smooth surfaces, and achieves the desired aesthetic.

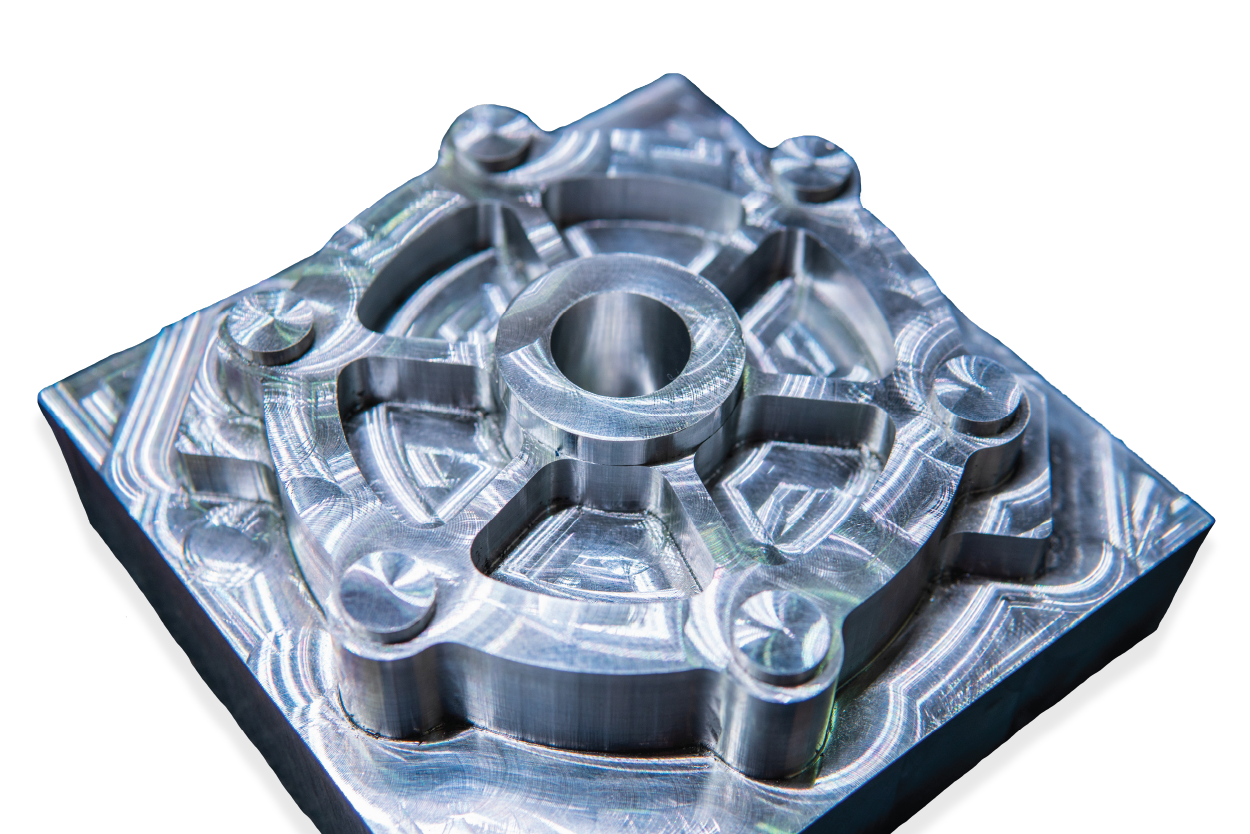

As Machined (Default)

The term “as machined” refers to the final state of a part or component after the complete manufacturing process, without additional finishing or post-processing steps. The part is delivered in its raw, unfinished condition directly from the machining operation.

Anodizing Levels II & III

Anodizing is a surface treatment process that creates a protective oxide layer on aluminum and other metals. Levels II and III refer to different thicknesses and properties of the anodized layer:

Level II Anodizing: This process produces an anodized layer, typically 0.0002-0.0004 inches thick. The increased thickness provides enhanced corrosion and wear resistance compared to standard anodizing.

Level III Anodizing: Also known as hardcoat anodizing, this process creates an even thicker anodized layer, typically 0.001-0.003 inches thick. The resulting hard, durable finish is highly complex and resistant to abrasion, corrosion, and wear.

Bead Blasting

Bead blasting is a surface finishing technique that utilizes small, spherical glass or ceramic beads to clean, smooth, or texture various materials. The process involves propelling the beads onto the target surface at high velocity, creating a uniform and consistent finish. Bead blasting is commonly employed in aerospace, automotive, and medical device manufacturing industries to improve the appearance and performance of components.

Black Oxide

Black oxide is a protective coating applied to metal surfaces to provide corrosion resistance and a uniform dark finish. It is commonly used on steel, iron, and other ferrous metals to enhance their appearance and durability. The black oxide process involves submerging the metal parts in a heated chemical solution. Subsequently, this solution reacts with the surface to create a thin, tightly adhered black oxide layer. Consequently, this coating helps prevent rust and oxidation, making it a popular choice for various industrial and consumer applications.

Chem Film

Chem film, or chemical conversion coating, is a surface treatment process that creates a thin, protective layer on metal surfaces. This process involves a chemical reaction between the metal and a conversion solution, forming a corrosion-resistant coating. Moreover, chem film is commonly used on aluminum, steel, and other metal parts to enhance their corrosion resistance, improve paint adhesion, and provide a uniform appearance.

Dry Film

Dry film is a photoresist material for manufacturing printed circuit boards (PCBs) and other electronic components. It is a thin, flexible sheet laminated onto a substrate’s surface, such as a copper-clad board. The dry film also acts as a protective mask, allowing specific areas to be exposed and etched during manufacturing. Moreover, this technique offers several advantages, including improved resolution, better edge definition, and easier handling than liquid photoresists. Therefore, dry film is crucial in producing high-quality, reliable electronic devices.

E-Coating

E-coating, also known as electrocoating or electrophoretic deposition, is a highly effective and versatile coating process used in various industries. It involves immersing a metal part in a water-based paint or coating solution and applying an electrical current. Consequently, the paint particles deposit and adhere uniformly to the surface. The process results in a durable, corrosion-resistant, and aesthetically pleasing finish ideal for various applications, from automotive parts to household appliances.

Epoxy Priming & Painting

Epoxy priming and painting are highly effective surface preparation and coating solutions for various industrial applications. The epoxy primer provides exceptional adhesion, corrosion resistance, and durability, creating a solid foundation for the topcoat. Additionally, the epoxy paint delivers a durable, chemical-resistant, and long-lasting finish that protects the underlying surface from environmental elements. This comprehensive system is commonly used in manufacturing, fabrication, and maintenance settings to ensure optimal performance and extended service life of critical components.

Galvanizing

Galvanizing applies a protective zinc coating to steel or iron to prevent rusting and corrosion. The steel is immersed in a molten zinc bath, forming a metallurgical bond with the underlying metal, creating a durable and long-lasting protective layer. This process enhances the lifespan and durability of metal components, making it a widely used technique in various industries, from construction to automotive manufacturing.

Graining (Brushing)

Graining or brushing is a finishing technique used in manufacturing to create a uniform, textured surface on metal parts. This process involves using specialized tools to apply a consistent pattern or grain to the material, enhancing its visual appeal and providing a unique tactile experience. Depending on the application’s specific requirements, the resulting surface can range from a subtle, satin-like finish to a more pronounced, industrial-inspired look.

Laser Engraving

Laser engraving is a precise and versatile manufacturing process that utilizes a focused laser beam to remove material from the surface of a workpiece. This technique enables the creation of intricate designs, logos, and text with exceptional detail and accuracy. Moreover, laser engraving is commonly utilized in various industries, including industrial, commercial, and consumer products, to personalize and incorporate unique branding elements into multiple materials, such as metal, plastic, and wood.

Passivation

Passivation creates a thin, stable, protective oxide layer on a metal surface, typically stainless steel, to enhance its corrosion resistance. This passive layer helps prevent the metal from reacting with its environment, making it more durable and resistant to corrosion, pitting, and other forms of degradation.

Plating (Electro - Nickel, Gold, Silver, & Zinc)

Electroplating is a versatile metal finishing process that involves depositing a thin layer of one metal onto the surface of another metal. Prototek offers electroplating services such as nickel, gold, silver, and zinc. Additionally, this process improves the appearance, corrosion resistance, and durability of the underlying metal, making it an essential technique in many manufacturing and fabrication applications.

Plating (Electroless - Nickel)

Electroless nickel plating is a chemical process that deposits a uniform, corrosion-resistant nickel coating onto various metal and non-metal surfaces without using an external electrical current. This process provides excellent wear resistance, hardness, and corrosion protection, making it a popular choice for various industrial applications.

Polishing

Polishing is a machining process that uses abrasive materials to create a smooth, glossy, and reflective surface finish on a workpiece. This process is typically performed after other machining operations, such as turning, milling, or grinding, to remove any remaining surface imperfections and achieve a desired level of surface finish. The polishing process can be done manually or using specialized machinery, and it is commonly used in various industries, including automotive, aerospace, and medical device manufacturing, to enhance the appearance and functionality of the final product.

Polishing (Electro)

Electro-polishing is an electrochemical process that smooths and brightens metal surfaces. It removes a thin material layer from the workpiece, resulting in a uniform, mirror-like finish. This process is commonly used to improve metal parts’ appearance and corrosion resistance.

Powder Coating

Powder coating is a dry finishing process that applies a durable, protective coating to a wide range of metal and plastic surfaces. The powder is electrostatically charged and then sprayed onto the item, creating a uniform, high-quality, attractive, and highly durable finish. Compared to traditional liquid paint finishes, powder coating offers superior protection against chipping, scratching, fading, and corrosion.

Priming & Painting

Priming and painting are standard finishing processes used in machining to enhance the appearance and protect the surface of the final part. Priming helps to create a smooth, uniform surface that improves the adhesion of the topcoat paint. The painting then provides a durable, protective layer to enhance the part’s resistance to corrosion, wear, and environmental elements.

Silk Screening

Silk screening is a versatile machining finish that involves applying ink or paint through a fine mesh screen. This process allows precise, high-quality graphics and patterns for various materials, including metals, plastics, and textiles. Silk screening is a popular choice for adding branding, logos, or decorative elements to finished products, providing a durable and visually appealing finish.

Smooth Machined

Smooth machining means creating a highly polished, uniform surface finish on a manufactured part. This process is typically achieved through precise control of the machining parameters, such as cutting speed, feed rate, and tool selection, to minimize surface irregularities and produce a smooth, consistent appearance.

Tumbling

Tumbling is a post-processing technique used in machining to improve metal parts’ surface finish and appearance. It involves placing the parts in a rotating barrel or drum filled with abrasive media, such as ceramic pellets or crushed walnut shells. As the barrel rotates, the parts are tumbled and polished, removing burrs, sharp edges, and improving the overall surface quality.

How to choose the right machine shop finishes or post-processing for your CNC project?

Choosing the appropriate machine shop finishes or post-processing for your CNC project is crucial for achieving your parts’ desired look, feel, and functionality. We offer various finishing options tailored to meet your requirements. Our team of experts can guide you through the selection process to ensure that your parts meet the highest quality standards. Whether you need a smooth, polished surface or a specialized coating, we have the capabilities and expertise to deliver exceptional results.

FAQs

Machine shop finishes include a variety of surface treatments to enhance appearance and functionality.

Chrome plating provides a shiny, durable metallic finish that enhances various surfaces’ appearance while offering resistance to corrosion and wear. On the other hand, chem film presents a protective, non-reflective coating that safeguards the underlying material, ensuring long-term durability and enhancing performance under various environmental conditions.

Zinc plating involves applying a thin zinc coating to a metal surface to provide some degree of corrosion resistance. In contrast, galvanizing consists in creating a thicker layer of zinc, which offers enhanced protection against rust and other forms of deterioration. This thicker layer makes galvanizing particularly suitable for items exposed to harsher environmental conditions, ensuring longevity and durability.

Painting and priming processes typically involve the application of liquid coatings that create a smooth and protective layer on surfaces. In contrast, powder coating is a distinct method that employs a dry powder that is electrostatically applied, which allows for a more durable finish. Once heated, this powder melts and forms a strong bond with the material, providing a long-lasting, more resilient protective layer than traditional liquid coatings.

Electroplating involves applying an electric current to deposit a metal coating onto a conductive surface. At the same time, electroless plating uses a chemical reduction process to deposit the coating without an external power source. The critical difference is the metal deposition method, leading to distinct advantages and applications for each technique.