Temperature Resistant

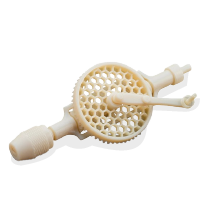

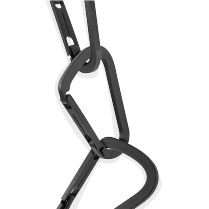

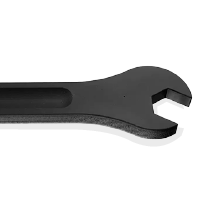

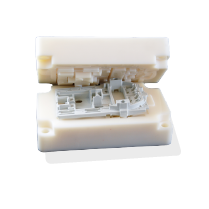

Additive manufacturing, also known as 3D printing, has revolutionized the way manufacturing is done. It has made it easier, faster, and cheaper to produce complex components that would have been difficult to make using traditional manufacturing methods. However, one of the challenges of additive manufacturing is that the components produced can often be prone to deformation or failure when exposed to high temperatures.

To address this challenge, it is essential to use materials with temperature-resistant properties to help ensure that the components retain their structural integrity and functionality in high-temperature environments. Such materials can withstand higher temperatures without degrading, warping, or losing strength and can help improve the reliability and durability of the components.

Temperature-resistant materials commonly used in additive manufacturing include thermoplastics, thermosets, and composites reinforced with ceramic or metal fibers. Choosing the suitable material for a particular component depends on factors such as the intended application, the operating temperature range, and the desired properties of the finished component.

In summary, using temperature-resistant materials can be crucial to the success of additive manufacturing, mainly when producing components exposed to high temperatures. By selecting the appropriate material for a particular application, manufacturers can ensure that their components perform reliably and meet the necessary specifications.

Showing all 15 results

-

Accura® SL 5530

Read more -

Accura® Xtreme

Read more -

Digital ABS Plus

Read more -

EPX 82

Read more -

EPX 86FR

Read more -

Glass Filled Nylon 12

Read more -

Nylon 12

Read more -

PC-ISO

Read more -

Polycarbonate PC

Read more -

RPU 130

Read more -

RPU 70

Read more -

Somos® PerFORM

Read more -

Somos® ProtoTherm

Read more -

Somos® Taurus

Read more -

Somos® WaterClear Ultra 10122

Read more